One-Stop Solution for PEEK & PI: Materials and Machining

Fast Turnaround: In-stock standard shapes; OEM orders typically ship in 7 days.

Advanced R&D supported by collaboration with Dalian University of Technology.

ISO 9001 & AS9100 Certified Quality Management System.

Contact Us

Allstar Material - Main Product Series

Dalian Allstar Material was established in 2008 and is among the first batch of Chinese factories to produce polyetheretherketone materials. Since our establishment, our main product series include polyetheretherketone PEEK materials, polyimide PI materials, and deep processing of these two materials, including CNC, automatic lathe processing, injection molding, compression molding, etc.

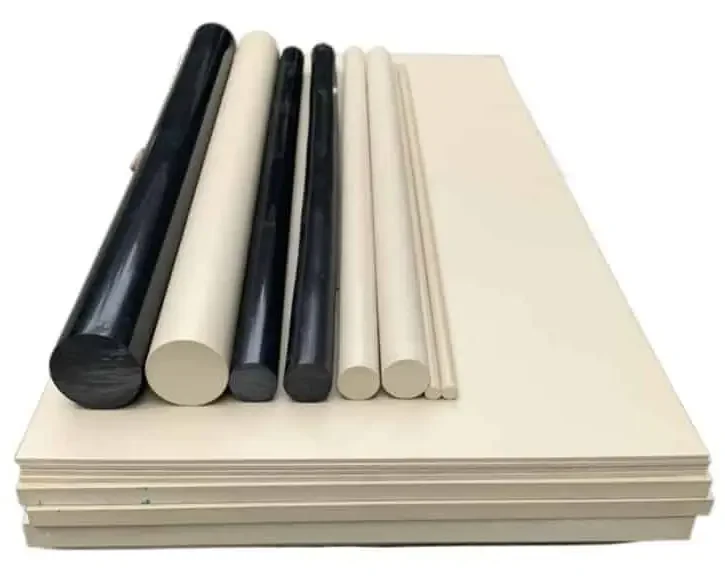

PEEK (Polyetheretherketone) Material Series

Polyetheretherketone PEEK material is one of our advantageous products. We can provide pure PEEK, CF30 carbon fiber reinforced, GF30 glass fiber reinforced, and bearing-grade PEEK products. Product forms include plates (0.5-100mm), rods (Φ1-200mm), tubes, and films, and we can provide injection molding, compression molding, precision machining, etc. At Allstar Material, we can solve all your PEEK needs.

PEEK materials can work normally at temperatures below 260 degrees Celsius, with high mechanical strength and good chemical stability, widely used in medical implants, automotive components, petroleum equipment, and other fields. Our company maintains large inventories to meet your selection needs. We cooperate with Dalian University of Technology in research and development to ensure stable product quality.

PI (Polyimide) Material Series

Polyimide PI is our specialty product. We can provide PI plates, PI rods, PI films, and other products, and can develop new products according to customer requirements. PI materials can be used continuously at 400 degrees Celsius, with excellent electrical insulation and dimensional stability.

Polyimide PI materials are mainly used in high-tech fields such as flexible circuit boards and aviation insulation components. Through years of research and development and practical application, we are well-versed in the core modification technology of PI materials and can customize different modified PI materials according to different customer needs. Just tell me your application environment, and I will recommend suitable PI materials for you. Trust me.

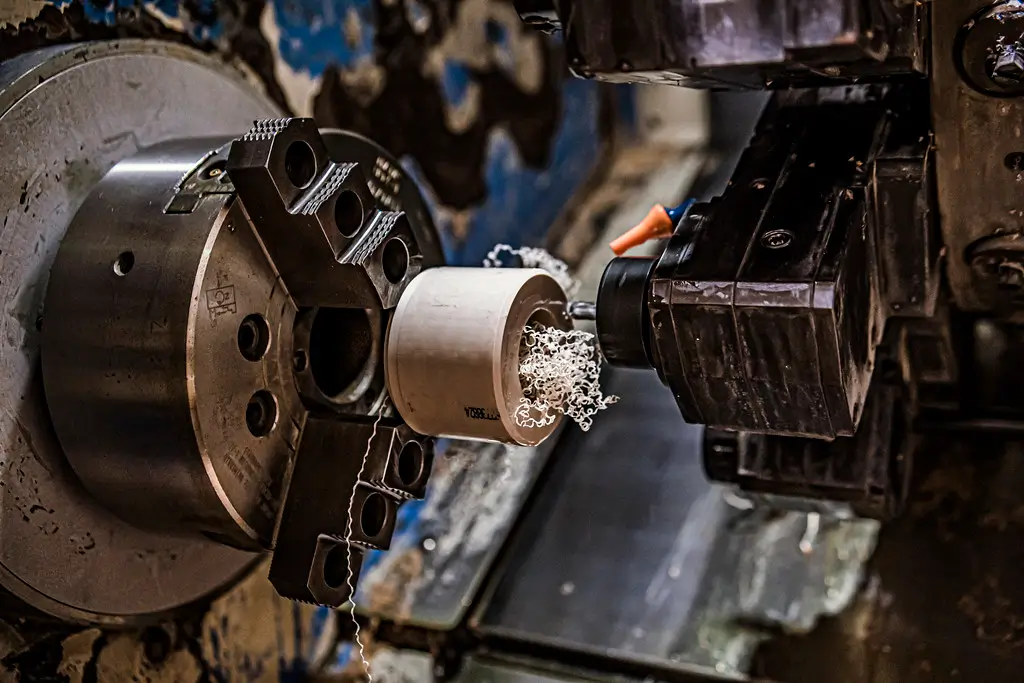

PEEK and PI Machining Services

We can not only provide PEEK and PI profiles such as plates, rods, and tubes, but also provide injection molded products, compression molded products, and precision CNC machining services. We can complete complex processes such as turning, milling, drilling, and grinding, covering everything from simple parts to complex structural components.

Our production and technical team has rich experience in engineering plastic processing, deeply understands material characteristics and process difficulties, and provides one-stop services from drawing design, industrial optimization to mass production. We support orders starting from 1 piece, meeting needs from small batches to large-scale production.

Pricing and Cost Advantages

Cost comparison display

Compared to products from other countries, saves 30-40% in costs

Outstanding cost-effectiveness

Compared to other global PEEK factories, same performance, better price

Volume discount policy

As a Chinese PEEK material factory, Dalian Allstar offers price discounts for bulk products, ensuring customer satisfaction with pricing.

About Dalian Allstar Material

Dalian Allstar has been deeply cultivating the engineering plastics field for over 15 years. With profound technical accumulation and market insights, it has developed into one of the top three PEEK material manufacturers in China. The company always adheres to innovation-driven development and maintains close industry-academia-research cooperation with Dalian University of Technology, ensuring a leading position in PEEK material research and production. We are committed to providing customers with excellent PEEK and PI products and customized solutions, having successfully served over 2,000 customers worldwide.

Contact Us

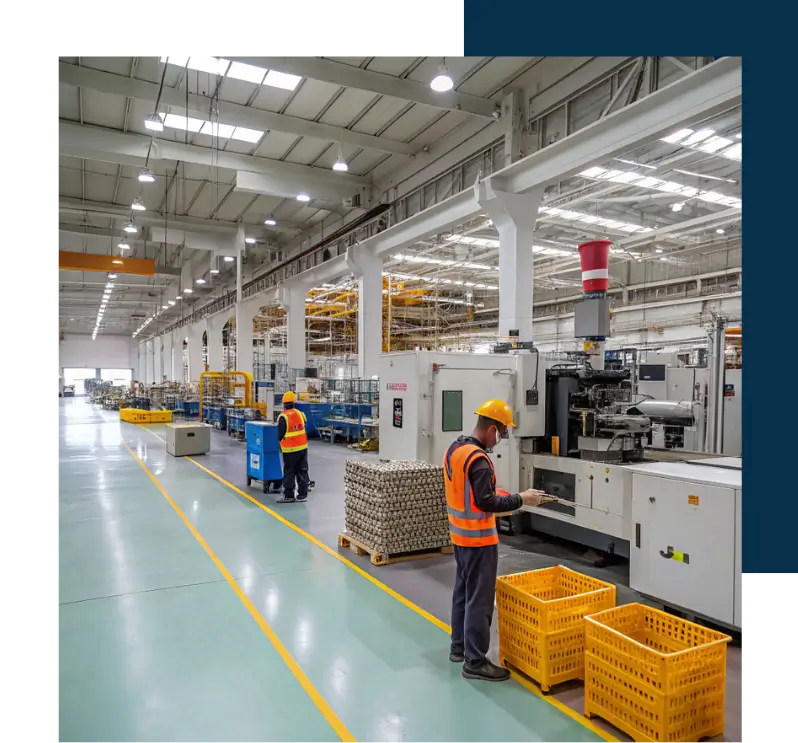

Work Shop

Dalian Allstar Material has four specialized production workshops equipped with over 150 pieces of precision machinery. These facilities cover the entire processing chain, including CNC machining, compression molding, injection molding, and precision turning.

We can achieve a processing accuracy of ±0.003mm and have a single-shift capacity of more than 5,000 units. We provide clients with a one-stop, precision machining service, from raw materials to finished products, ensuring a product quality stability of over 99.5%.

CNC Work Shop

Equipped with over 20 German-imported multi-axis CNC machining centers, we specialize in processing precision PEEK and PI components. Our processing accuracy can reach ±0.005mm, with a maximum machining size of 2000×1500×800mm. We are capable of handling complex processes such as turning, milling, drilling, and grinding, producing everything from simple parts to complex structural components that meet strict aerospace-grade tolerance requirements.

Moulding Work Shop

Injection Work Shop

Turning Work Shop

Applications of PEEK

Polyetheretherketone (PEEK) material, with its various performance advantages, has become one of the indispensable key materials in modern high-tech fields. Based on our company's years of production and application experience, we will deeply explore the specific applications of PEEK materials in core industries such as healthcare, new energy vehicles, petrochemical and natural gas, and electronic semiconductors.

Healthcare

In the medical field, PEEK has become a preferred material for human implants due to its high biocompatibility, sterilization resistance, and X-ray translucency. It is widely used in spinal fusion cages (its elastic modulus of about 3.8 GPa is close to that of human bone, reducing stress shielding and promoting bone healing), trauma fixation plates, and dental implants. The material's transparency to X-rays allows for clear post-operative observation. Furthermore, it can withstand repeated high-temperature sterilization, ensuring patient safety and a smooth recovery.

New Energy Vehicles

The new energy vehicle industry has high demands for lightweight and high-performance materials. PEEK has become a primary alternative to metal, thanks to its high strength, wear resistance, heat resistance, and chemical inertness. It is often used to manufacture engine piston rings, transmission gears, fuel system seals, and electrical connectors. PEEK not only increases the service life of components but also improves fuel efficiency.

Petrochemical and Natural Gas

PEEK material excels in petrochemical and natural gas applications due to its high resistance to chemical corrosion, high temperatures and pressures, and its self-lubricating properties. It is widely used to manufacture seals, valve seats, bearings, and pump components for downhole oil equipment. PEEK can effectively withstand hydrocarbons, corrosive fluids, and high-pressure environments, which reduces maintenance costs and extends the lifespan of equipment.

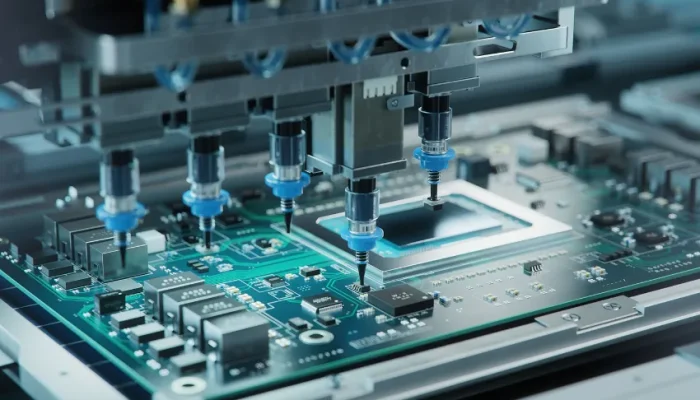

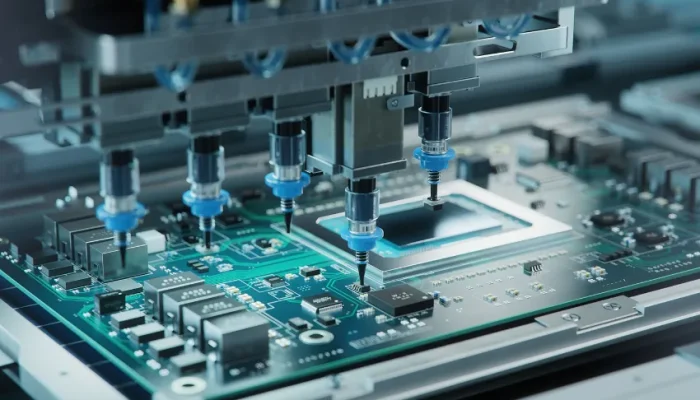

Electronics and Semiconductors

In the electronics and semiconductor industries, PEEK's high-temperature resistance, low moisture absorption, high purity, and low particle generation are crucial for its applications. It is used to manufacture wafer carriers and test sockets, among other components. The use of PEEK effectively improves wafer yield and production efficiency, meeting the stringent material requirements of the semiconductor industry.

Service Guarantees & Risk Elimination

After-Sales Service

24/7 response with dedicated customer service follow-up.

Quality Assurance

100% replacement for all non-conforming products.

Technical Support

Free lifetime technical consultation.

Delivery Guarantee

We take responsibility for delayed deliveries, with an on-time delivery rate of 99.5%.

Product Delivery

All products are 100% inspected at the time of shipment, including dimensions and appearance.

Allstar Material: Our Advantageous PEEK Products

PEEK Films

Advanced Film Solutions for Modern Technology

Applications in Electric Vehicles

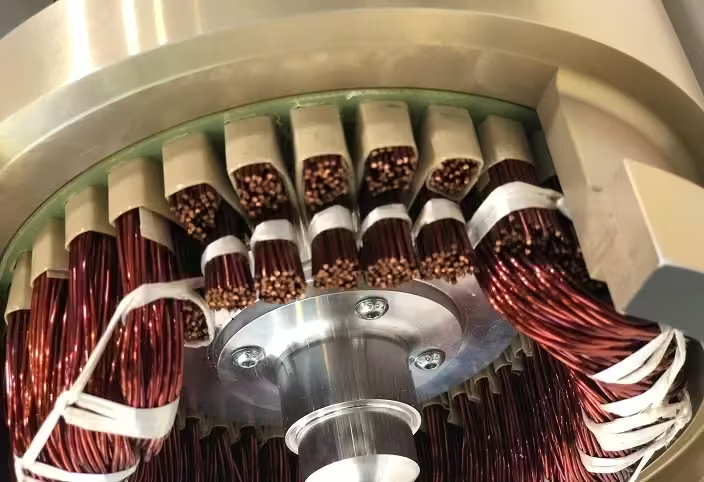

PEEK film is mainly used in electric vehicles for battery separators, motor insulation layers, cable sheaths, etc. Due to PEEK material's excellent electrical insulation and high temperature resistance, it can ensure safety during operation and prevent loss of control due to excessive temperature.

As insulation film in motor windings, PEEK can provide reliable electrical isolation. PEEK film is used as insulation layer for high-voltage cables to prevent high-voltage breakdown.

Contact Us

Applications in the Audio Field

PEEK film is the best material for manufacturing high-performance speaker diaphragms. It has unique rigidity and flexibility, can effectively control the resonant frequency of the diaphragm, achieve broader frequency response and more accurate sound reproduction while reducing distortion. PEEK diaphragms can withstand high energy input and long-term use without easy deformation or fatigue, ensuring long-term sound quality stability.

Contact Us

PEEK Cable Ties

High-Performance Bundling for Extreme Environments

Aerospace

PEEK cable ties are used for wire harness bundling and fixation in aircraft, especially in high-temperature, high-pressure, fire-resistant, and corrosion-resistant environments such as engine compartments and avionics equipment.

KEY APPLICATIONS:

- Engine compartments

- Avionics equipment

- High-temperature environments

- Fire-resistant zones

- Corrosion-resistant areas

Automotive Industry

In automotive engine compartments, transmissions, and electrical systems, PEEK cable ties are used to secure cables and pipelines. Their high temperature resistance, oil contamination resistance, and chemical corrosion resistance characteristics enable them to maintain reliability in harsh automotive operating environments.

KEY APPLICATIONS:

- Engine compartments

- Transmission systems

- Electrical harnesses

- Pipeline securing

- High-temperature zones

Contact Us

PEEK Cables

Mission-Critical Performance in Extreme Conditions

Nuclear Power

In nuclear power plant reactor interiors and surrounding areas, PEEK cables are used for control systems, sensors, and monitoring equipment. Due to PEEK material's excellent radiation resistance and high temperature performance, ensuring safety and reliability in strong radiation environments.

Electric Vehicles

In electric vehicle battery modules, motor windings, and high-voltage distribution systems, PEEK cables are used to enhance electric vehicle safety, efficiency, and lifespan due to their high temperature resistance, high voltage insulation, and flame retardant characteristics.

Oil & Gas Downhole

In deep-sea drilling, high-temperature high-pressure oil and gas downhole exploration and production equipment, PEEK cables serve as sensor cables, data transmission lines, and power cables, capable of resisting extreme temperatures, high-pressure fluids, and various corrosive chemical erosion, ensuring long-term stable operation.

PEEK Cable Ties

High-Performance Bundling for Extreme Environments

Water-Lubricated Bearings

Water-lubricated bearings are critical components of pumps. They bear the axial force of the pump's rotating parts and stabilize the rotation of the impeller. If the bearing wears excessively or is severely damaged, it can lead to increased axial play in the unit, severe vibration, and even impeller rubbing.

Most pump failures during operation are due to water-lubricated bearing failures. Therefore, these bearings are a key controlling factor for a pump's reliability, service life, and planned overhaul cycle.

Plunger Pumps

Our company's modified PEEK materials offer a range of advantages, including high mechanical strength, high-temperature resistance, self-lubricating properties, corrosion resistance, and excellent dimensional stability.

When our modified PEEK is paired with stainless steel as a plunger and slipper pad, the pump operates with high efficiency and stability while minimizing wear.

Contact Us

cooperative clients

In 2011, we collaborated with the Victrex to jointly develop composite material applications with Sulzer, and achieved mass production in 2013. Replace the import of WR300/AR1/ARHT bearings from the United States to achieve localization; BB3/BB4 series pumps have a large number of applications for pump body sealing rings.

In 2023, became a qualified supplier of Andritz, successfully replaced Weir’s Vanchem composite materials produced in South Africa, and achieved full coverage application in Andritz’s new pump production and spare parts maintenance market.

In 2022, became a qualified supplier of Desmi, applied new composite materials to replace traditional metal materials, achieving the application effects of no seizing, small clearances, and high pump efficiency, which received high recognition from the Danish headquarters and global promotion. Meanwhile, in 2023, continued to develop the magnetic pump containment shell project with them, and the products are currently undergoing operational verification in Denmark.

“Our company provides PEEK continuous carbon fiber composite material seal rings to Dalian Leo Pump, a subsidiary of Leo Group, to replace imported Greene Tweed WR525 series products for export to Russia and Europe.

Our company provides PEEK composite material wear rings to Hunan Leo Pump, a subsidiary of Leo Group, to replace traditional metal materials and improve low-temperature seizing conditions.”

Global OEM Solutions Partner

We manufacture high-performance, reliable PEEK and PI products for global Original Equipment Manufacturers (OEMs). We offer comprehensive solutions, from standard stock shapes (rods/sheets/tubes) to precision-machined parts.

Contact Us

FAQ

What's the minimum order quantity for PEEK materials?

We understand that different projects have varying material requirements. At Dalian Allstar Materials, we offer flexible ordering options:

Standard Stock Shapes (rods, sheets, tubes): 1 piece minimum order – Perfect for prototyping, testing, or small-scale projects

Custom Machined Parts: 1 piece minimum – We support everything from single prototypes to large-scale production runs

Bulk Raw Materials: 10kg minimum for granules and powders

Special Grades/Modifications: Minimum quantities may vary based on specific requirements

What certifications do your materials have?

Quality and compliance are fundamental to our operations. Our comprehensive certification portfolio includes:

Company Certifications:

ISO 9001:2015 – Quality Management System

AS9100D – Aerospace Quality Management System

ISO 14001 – Environmental Management System

ISO 45001 – Occupational Health & Safety Management

Testing Standards Compliance:

ASTM D638 (Tensile Properties)

ASTM D790 (Flexural Properties)

ASTM D256 (Impact Resistance)

ISO 11357 (Thermal Analysis)

Can you provide material test certificates?

Absolutely! Documentation and traceability are core to our quality assurance system.

Certificate of Compliance (CoC) – Confirms material meets specified standards

Material Specification Sheet – Detailed technical properties

Batch/Lot Traceability – Complete production history

Dimensional Inspection Report – For machined parts