PEEK Injection Molding

PEEK (polyether ether ketone) injection molding is a process in which high-temperature PEEK resin pellets are melted and injected under high pressure into precision mold cavities and then cooled and cured to produce the final product. This process allows for the production of complex geometries and tight tolerances.

This process is particularly suitable for high volume production of parts, and the excellent properties of PEEK, combined with the high efficiency and repeatability of injection molding, make it an ideal choice for many demanding industrial applications.

Allstar Material's Advantages in PEEK Injection Molding

Allstar Materials offers advanced expertise in PEEK injection molding, delivering high-precision, durable components with excellent thermal and chemical resistance for critical industrial applications.

In-depth Profound Material Expertise

Expert in a wide range of PEEK grades, including unfilled, glass fiber, carbon fiber reinforced, and abrasion-resistant types. We offer deep material knowledge to help you choose the best grade for your application.

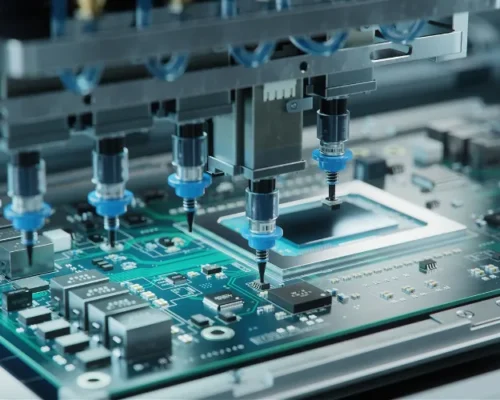

Advanced Processing Capabilities

We have high-precision injection molding equipment designed specifically for high-temperature engineering plastics such as PEEK.

Stringent Quality Assurance

Each product is inspected from raw material to final product.

Precision Mold Design & Manufacturing

We can provide or assist in the design and manufacture of precision molds to ensure mold accuracy and life.

Custom PEEK with support.

Experienced engineering teams provide technical support from design optimization to volume production, dedicated to meeting our customers' unique performance and cost requirements.

Reliable Delivery Capability

42 injection molding machines and an efficient operations management team ensure on-time delivery of high-quality PEEK injection molded parts.

Allstar Material's PEEK Injection Molding Process

Allstar's PEEK injection molding process has been carefully designed and strictly controlled to ensure the highest quality:

Material Preparation

PEEK resin must be dried before use. OSTAR's process generally consists of drying the peek pellets in a vacuum dryer at 150°C to 160°C (302°F - 320°F) for 4-6 hours to eliminate moisture and prevent hydrolytic degradation of the material during high temperature processing. (This is a critical step.)

Precise Melting & Injection

Dried PEEK pellets are temperature controlled in the barrel of the injection molding machine in segments: rear (feed zone): 340°C - 360°C, middle (compression zone): 350°C - 380°C, front (metering zone): 360°C - 400°C, and nozzle: 360°C - 400°C (slightly lower to prevent drooling). Molten PEEK is injected under high pressure into a mold cavity preheated to a specific temperature in a fast and stable manner.

Optimized Mold Temperature Control

Mold temperature is critical to the crystallinity, dimensional stability and surface finish of PEEK parts. Mold temperatures typically need to be set between 150°C and 200°C (302°F - 392°F) in order to achieve highly crystalline parts. Mold temperatures (<150°C) result in amorphous or low crystallinity parts, which are typically brittle and have poor chemical and fatigue resistance.

Controlled Cooling & Demolding

After the injection and pressure holding phases, sufficient cooling time is required to allow the part to fully cure in the hot mold and achieve a certain level of rigidity so that it can be smoothly demolded without distortion. The cooling time depends mainly on the wall thickness of the part, the larger the wall thickness, the longer the cooling time.

Post-Processing & Inspection

Depending on the customer's requirements, de-gating, trimming or other secondary processes may be performed. All products are inspected for dimensions and appearance and, if necessary, are tested for performance.

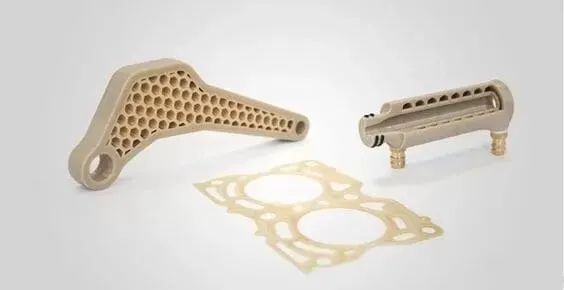

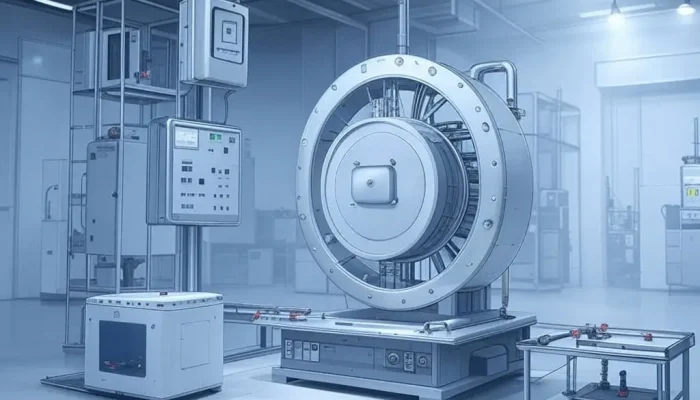

Applications of PEEK Injection Molding

PEEK injection molded parts are widely used in aerospace, automotive (including electric vehicles), medical devices, electrical and electronic and industrial equipment and other fields. It is characterized by high temperature resistance, abrasion resistance, chemical resistance and high strength. Dalian Ou Shi Da can provide customized PEEK injection molding solutions for specific markets such as nuclear power, military and bearings.

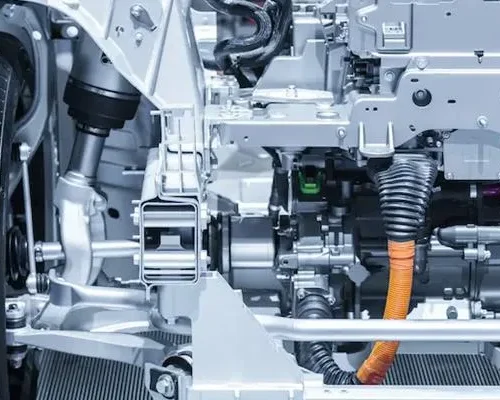

Automotive

engine components, transmission parts (e.g. thrust washers, sealing rings), high temperature and high voltage insulation, sensor housings.

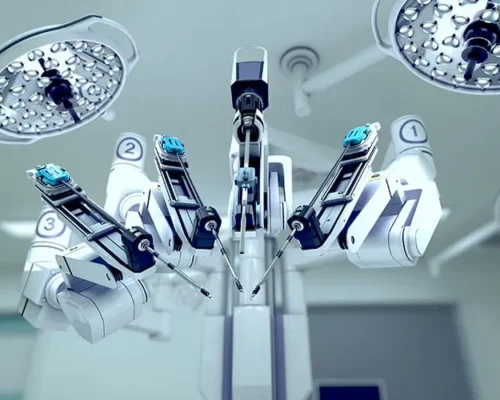

Medical Devices

Implantable grade PEEK is used for orthopedic implants, surgical instrument handles, and re-sterilized parts.

Electrical & Electronic

High temperature connectors, coil bobbins, insulators, wafer carriers.

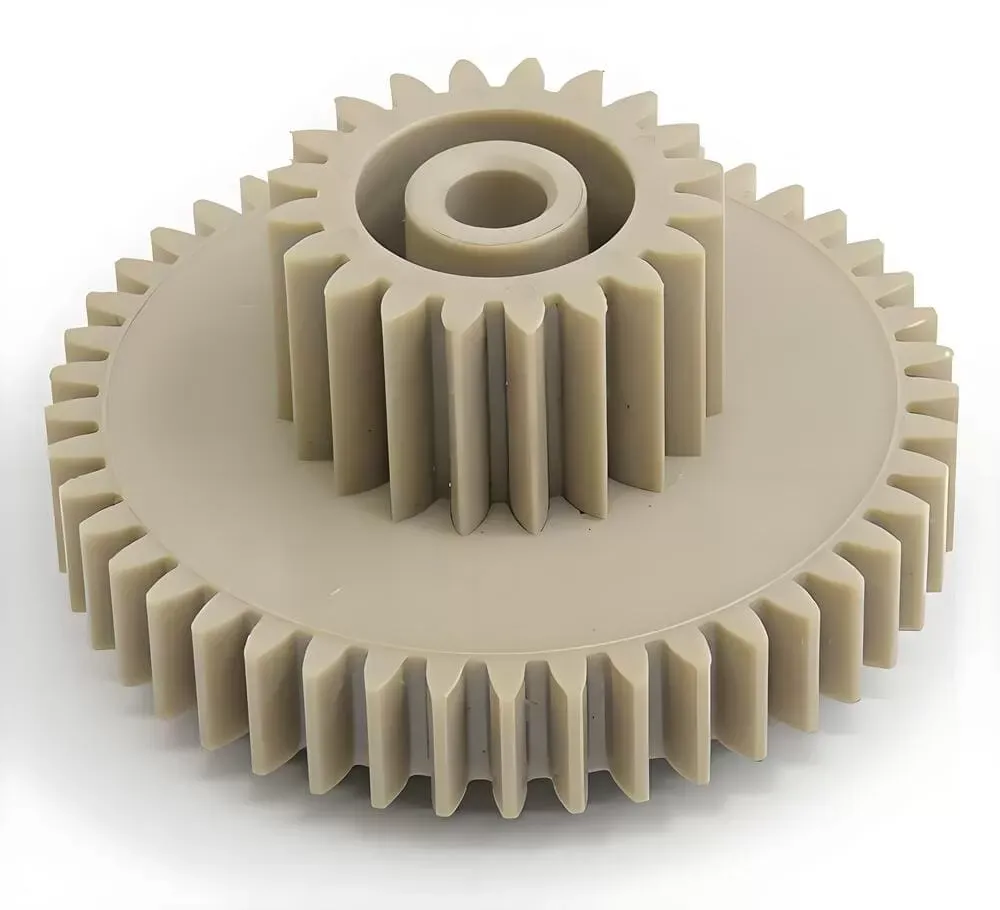

Industrial Equipment

Pump and valve components, gears, bearing cages, compressor valve plates, seals.

Oil & Gas

Downhole tool components, seals, corrosion and high pressure resistant components.

Sustainability and Environmental Protection in PEEK Injection Molding

PEEK materials are durable, which reduces the number of part replacements and increases service life. The lightweight nature of PEEK helps to reduce energy consumption in end-use applications. Dalian Ouestar is committed to optimizing production processes to minimize energy consumption and waste generation. We aim to provide PEEK injection molding solutions that combine high performance with environmental friendliness.

Material durability

PEEK materials have an inherently long life, reducing the frequency of part replacement and helping to reduce long-term resource consumption.

Lightweighting potential

The use of PEEK as a replacement for metal parts allows for lightweighting, which contributes to lower energy consumption for transportation and operation (especially in the automotive and aerospace sectors).

Process efficiency optimization

Production processes are continuously optimized to minimize energy consumption and waste generation. Clean trimmings from production are considered for recycling where technology permits.

Long-term cooperation

The aim is to establish a long-term relationship with our customers to jointly develop more environmentally friendly and efficient solutions.

Choose Dalian Allstar to get the high-performance PEEK injection molded parts you need.

We look forward to working with you to drive the success of your project. Contact us today to discuss your specific needs.