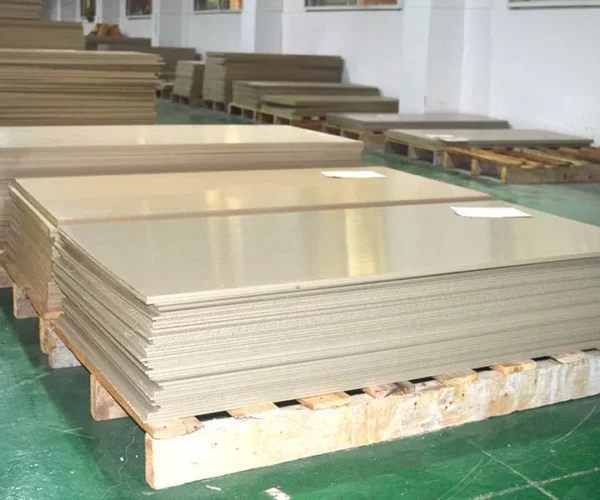

PEEK Plates and Sheets

PEEK (Polyetheretherketone) plates and sheets are semi-finished profiles manufactured from high-performance PEEK thermoplastic resin via extrusion or compression molding. These forms offer flat stock material in defined thicknesses, providing a base for subsequent precision machining (e.g., milling, turning, drilling) to create diverse high-performance engineering components.

The material exhibits exceptional high-temperature resistance, excellent mechanical strength and stiffness, outstanding chemical resistance, and good dimensional stability.

PEEK plates are widely utilized in industrial sectors demanding performance under harsh environmental conditions (e.g., high temperature, high pressure, corrosion, radiation).

Common Classifications of PEEK Plates and Sheets

According to diverse application requirements, PEEK plates are commonly modified through the addition of reinforcing fillers to optimize specific properties. Key classifications include:

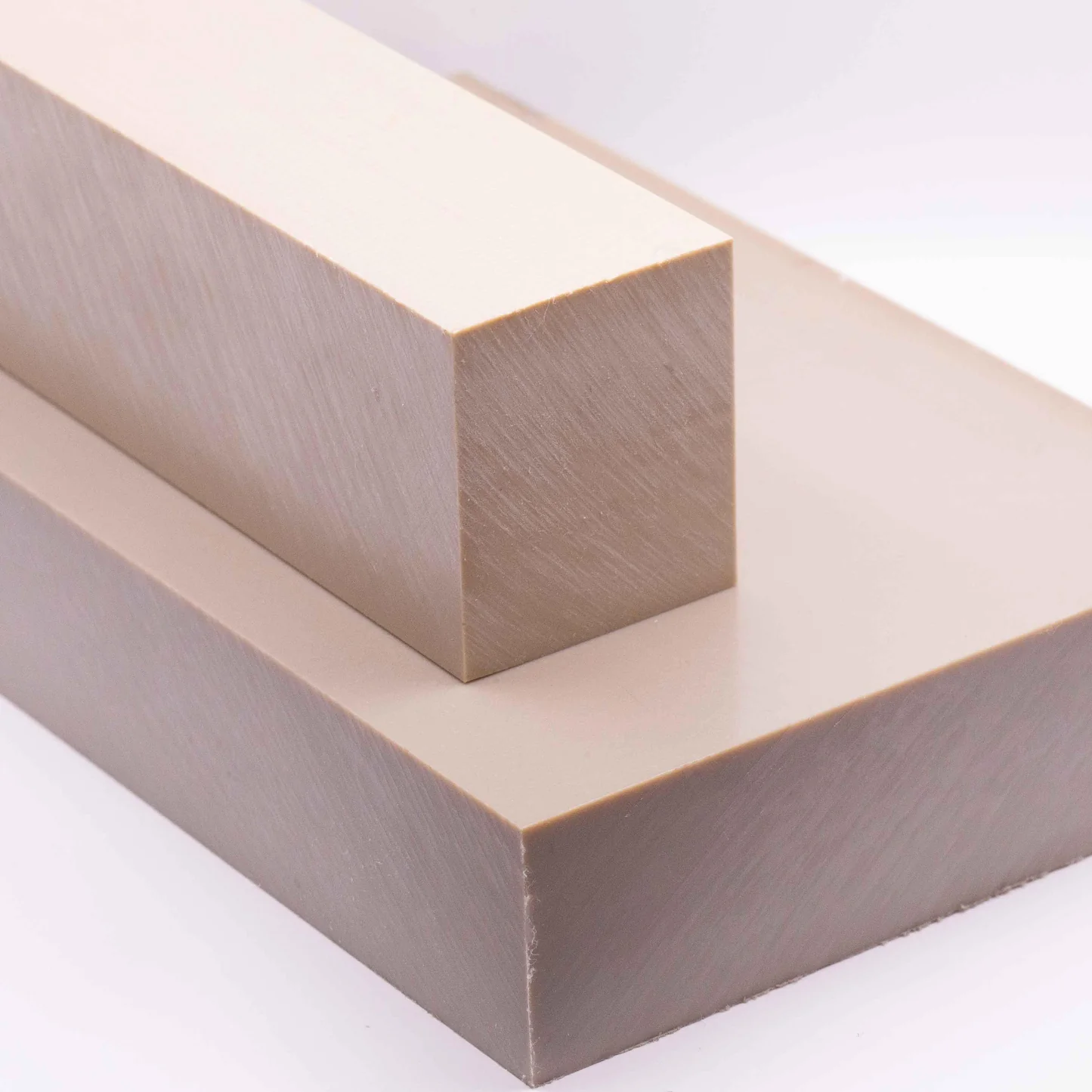

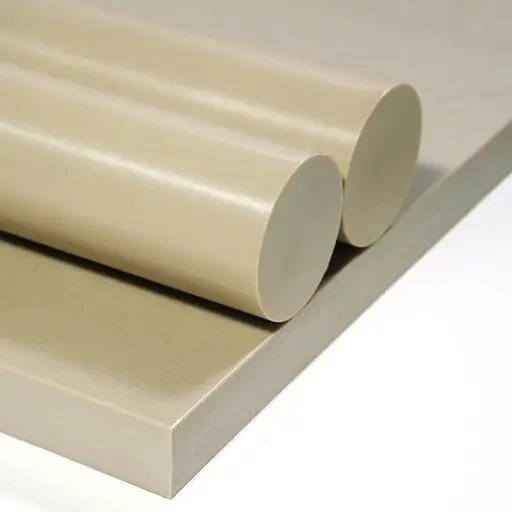

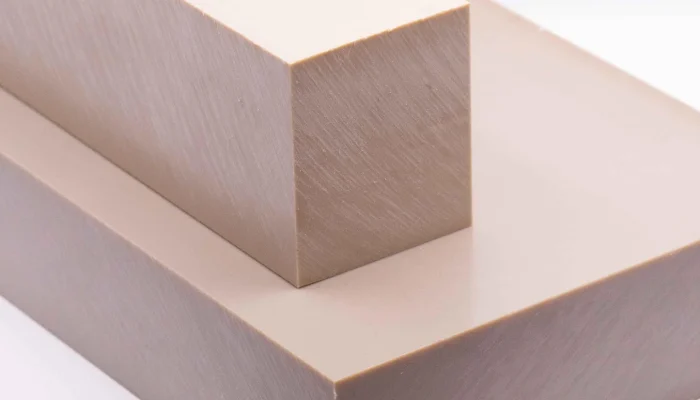

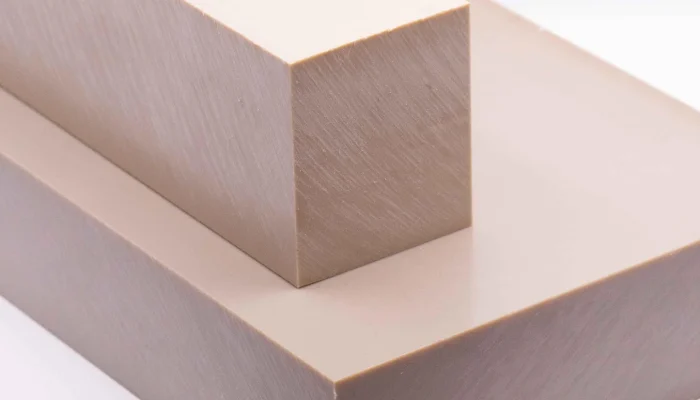

Unfilled PEEK Plate (Natural PEEK)

These plates are manufactured from pure PEEK resin without added reinforcing fibers or fillers. They exhibit the inherent, well-balanced properties of PEEK, including good toughness, ductility, excellent electrical insulation, and availability in FDA-compliant grades for food and medical contact applications.

30% Glass Fiber Reinforced PEEK Plate

Uniformly compounded with 30% (by weight) short glass fibers within the PEEK resin. The inclusion of glass fibers significantly enhances the material's stiffness (modulus), mechanical strength, and creep resistance. It also reduces the coefficient of linear thermal expansion (CLTE), improving dimensional stability, particularly at elevated temperatures. Toughness is slightly reduced compared to unfilled PEEK.

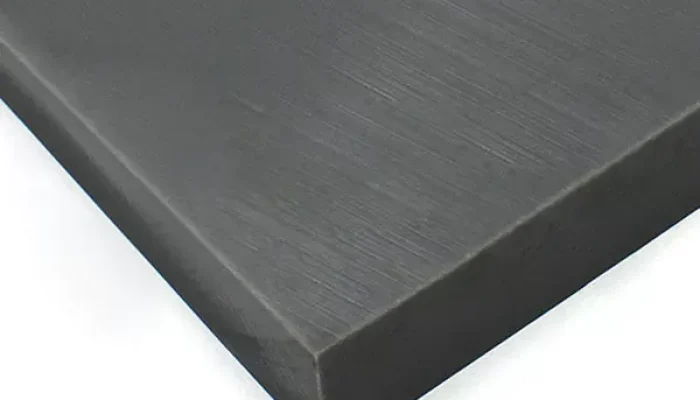

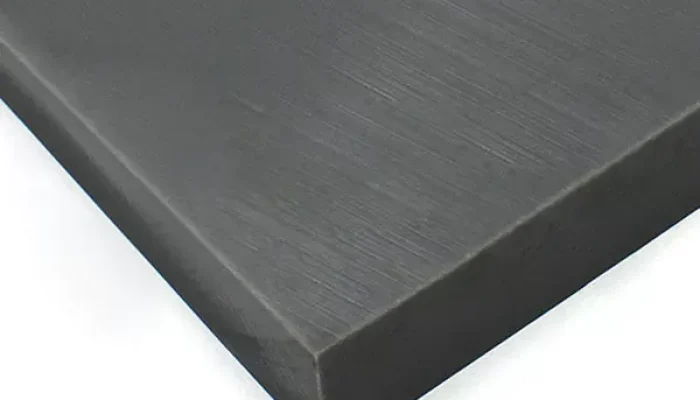

30% Carbon Fiber Reinforced PEEK Plate

Uniformly compounded with 30% (by weight) carbon fibers within the PEEK resin. Carbon fibers provide higher stiffness and strength compared to glass fibers, coupled with excellent wear resistance and a lower coefficient of thermal expansion. A key characteristic is that the addition of carbon fiber makes the material conductive or anti-static; it is no longer an electrical insulator. This grade exhibits the highest hardness but may be more brittle than GF30 PEEK.

Key Classification Performance Data Comparison

The following table outlines typical physical property data for these three common PEEK plate classifications for reference purposes. Specific values can vary slightly based on grade and testing conditions. For precise data, please refer to the specific product Technical Data Sheet (TDS) provided by Dalian Oushida.

|

Property |

Unit |

Unfilled PEEK |

PEEK GF30 |

PEEK CF30 |

|---|---|---|---|---|

|

Density |

g/cm³ |

~ 1.31 |

~ 1.51 |

~ 1.41 |

|

Tensile Strength |

MPa |

~ 95 |

~ 155 |

~ 210 |

|

Tensile Modulus |

GPa (MPa) |

~ 3.7 (3700) |

~ 9.7 (9700) |

~ 18.0 (18000) |

|

Flexural Modulus |

GPa (MPa) |

~ 3.9 (3900) |

~ 8.5 (8500) |

~ 16.0 (16000) |

|

Heat Deflection Temp (HDT) @ 1.8MPa |

°C |

~ 152 |

~ 315 |

~ 315 |

|

Continuous Use Temperature |

°C |

~ 250 |

~ 250 |

~ 250 |

|

Coefficient of Linear Thermal Expansion (CLTE, 23-150°C) |

µm/(m·°C) |

~ 50 |

~ 22 |

~ 18 |

|

Volume Resistivity |

Ohm·cm |

> 10¹⁴ (Insulated) |

> 10¹³ (Insulated) |

10³ - 10⁶(Antistatic/conductive) |

30% Glass Fiber Reinforced PEEK Plate

Note: Weight per meter is calculated based on the density of unfilled PEEK (approx. 1.31 g/cm³) and is provided for reference only. The actual weight of filled-grade PEEK plates will vary due to different densities. Please contact us for precise weight information regarding specific grades.

Dalian Allstar PEEK Plate Stock Specifications

Dalian Allstar regularly stocks the following standard PEEK plate specifications to ensure a rapid response to customer needs. Custom production services are also available according to your specific size or grade requirements.

|

Thickness(mm) |

Width(mm) |

Length(mm) |

Approx. Weight per Meter (kg/m)* |

|---|---|---|---|

|

0.3 |

600 |

3000 |

3.14 |

|

5 |

600 |

3000 |

3.93 |

|

6 |

600 |

3000 |

4.72 |

|

8 |

600 |

3000 |

6.29 |

|

10 |

600 |

3000 |

7.86 |

|

12 |

600 |

3000 |

9.43 |

|

15 |

600 |

3000 |

11.79 |

|

20 |

600 |

3000 |

15.72 |

|

25 |

600 |

3000 |

19.65 |

|

30 |

600 |

3000 |

23.58 |

|

35 |

600 |

3000 |

27.51 |

|

40 |

600 |

3000 |

31.44 |

|

45 |

600 |

3000 |

35.37 |

|

50 |

600 |

3000 |

39.3 |

|

55 |

600 |

3000 |

43.23 |

|

60 |

600 |

3000 |

47.16 |

|

65 |

600 |

3000 |

51.09 |

|

70 |

600 |

3000 |

55.02 |

|

75 |

600 |

3000 |

58.95 |

|

80 |

600 |

3000 |

62.88 |

|

85 |

600 |

3000 |

66.81 |

|

95 |

600 |

3000 |

70.74 |

|

95 |

600 |

3000 |

74.67 |

|

100 |

600 |

3000 |

78.6 |

|

105 |

600 |

3000 |

82.53 |

|

110 |

600 |

3000 |

86.46 |

|

115 |

600 |

3000 |

90.39 |

|

120 |

600 |

3000 |

94.32 |

Note: Weight per meter is calculated based on the density of unfilled PEEK (approx. 1.31 g/cm³) and is provided for reference only. The actual weight of filled-grade PEEK plates will vary due to different densities. Please contact us for precise weight information regarding specific grades.

Application Areas and Typical Products for Different PEEK Plates

PEEK plates are used across various industries, with applications ranging from medical implants to aerospace, automotive, and semiconductor components, depending on the plate type and grade.

Unfilled PEEK Plate:

Application Areas

Situations requiring good toughness, chemical resistance, hydrolysis resistance, electrical insulation, and biocompatibility (specific grades). Commonly found in medical devices, food processing, semiconductor, aerospace, chemical equipment, etc.

Typical Products

Seals, gaskets, bushings (low load), valve seats, electrical insulators, connectors, medical implants (certified grades required), food contact parts, wafer carriers, etc.

GF30 PEEK Plate:

Application Areas

Structural applications demanding high rigidity, high strength, excellent dimensional stability (especially at high temperatures), and good chemical resistance. Suitable for aerospace, automotive, oil & gas, industrial equipment, etc.

Typical Products

High-temperature structural components, pump bodies, impellers, valve components, bearing cages, gears, mechanical parts requiring tight tolerances, high-temperature insulating parts (still offers some insulation).

CF30 PEEK Plate:

Application Areas

Applications requiring extreme rigidity and strength, outstanding wear resistance, low coefficient of friction, and static dissipative or conductive properties. Common in high-performance industrial, motorsports, aerospace, semiconductor manufacturing equipment, etc.

Typical Products

High-load bearings, bushings, wear strips/sliders, gears, seal rings (dynamic seals), compressor piston rings, wafer handling components (anti-static required), high-strength lightweight structural parts (non-insulating).

Choosing Dalian Allstar as your PEEK plate supplier ensures reliable material quality, stable stock availability, and professional technical support.

Feel free to contact us anytime to discuss your specific application needs, request samples, or obtain a quotation.