Properties of pure polyimide (PI) materials

High-temperature stability

Mechanical properties

Electrical insulation properties

Chemical stability and corrosion resistance

Dimensional stability

Allstar Material's processing method for pure polyimide

Molding

Casting

Lamination

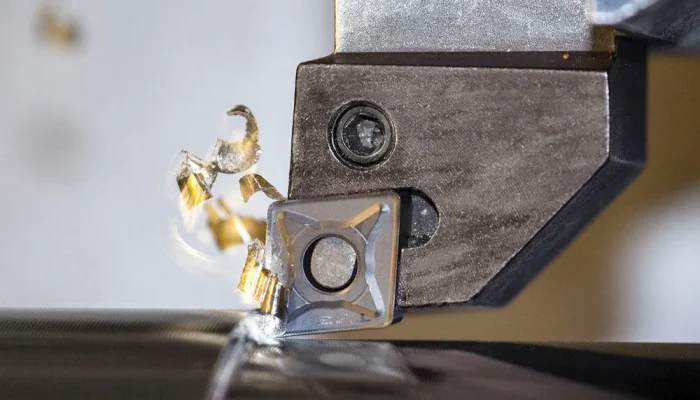

Machining

Advantages of Pure PI

Pure PI (Pure Polyimide) is a core material for extreme operating conditions. It maintains excellent dimensional stability and mechanical strength at temperatures exceeding 260°C. Its superior electrical insulation (dielectric strength 15-25 kV/mm), combined with chemical and radiation resistance, allows for wide application. Extremely low outgassing in vacuum (TML<1%) ensures its reliability in high-purity applications such as aerospace and semiconductors.

High temperature stability

Glass transition temperature (Tg): 250–400 ℃

Decomposition temperature (5% mass loss): 500–600 ℃

Continuous use temperature: Approximately 250–300 ℃

Many thermoplastics (such as PEEK) begin to degrade near 250 ℃, while PI retains its properties even under prolonged exposure to high temperatures.

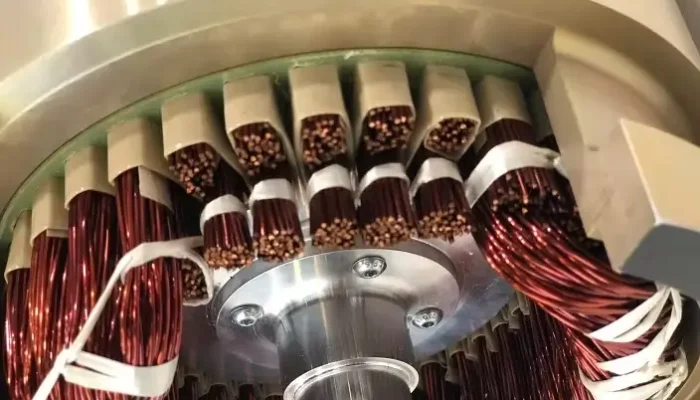

Electrical insulation properties

Dielectric constant: Approximately 3.0–3.5 (1 kHz, 25°C)

Dielectric loss factor: Approximately 10⁻³–10⁻², exhibiting low loss at high frequencies

Insulation breakdown strength: Approximately 100–300 kV/mm

Electrical strength: Can reach 20–30 kV/mm, ensuring its insulation performance in high-voltage environments.

Mechanical properties

Pure polyimide (PI) exhibits outstanding mechanical properties, particularly maintaining high strength and rigidity even at high temperatures.

Tensile strength: 50-125 MPa (data may vary slightly depending on the grade)

Flexural strength: 80-180 MPa

Elongation at break: 1–5%

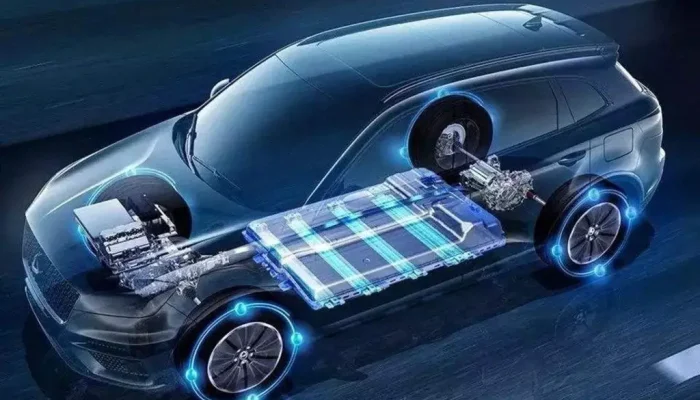

Creep resistance: PI's high-temperature creep resistance makes it ideal for applications subjected to prolonged mechanical stress, such as high-strength components in the aerospace and automotive industries."

Dimensional stability

Pure polyimide exhibits excellent dimensional stability, maintaining its shape even under high temperature or humid conditions.

Coefficient of Thermal Expansion (CTE): Approximately 20–50 × 10⁻⁶ /K, significantly lower than most thermoplastics (e.g., PEI ≈ 47 × 10⁻⁶ /K).

Water Absorption: Typically less than 1%, maintaining stable physical dimensions even in high humidity environments.

Long-Term Stability: PI maintains stable dimensions and properties even in high temperature and high humidity environments.

Advantages: Minimal dimensional changes, making it particularly suitable for high-precision parts, such as electronic components and aerospace precision parts.

Chemical stability and corrosion resistance

Pure polyimide exhibits excellent resistance to a wide range of chemicals, including strong acids, strong bases, and various solvents, thus performing exceptionally well in harsh chemical environments.

Acid resistance: It has excellent resistance to strong acids such as sulfuric acid, hydrochloric acid, and hydrofluoric acid, and can be exposed to these acids for extended periods without degradation.

Alkali resistance: It is resistant to most alkaline solutions and remains stable even in concentrated sodium hydroxide.Solvent resistance: Resistant to a variety of organic solvents, including alcohols, ketones, and hydrocarbons.

Oxidation resistance: PI exhibits excellent oxidative stability and can withstand high-temperature oxidizing environments.

Advantages: Highly reliable in chemically corrosive environments, commonly used in chemical equipment, automotive parts, and aerospace applications.

Your Trusted Pure PI Precision Machining Partner from China

As a professional manufacturer in the field of high-performance engineering plastics, Dalian Allstar Material Co., Ltd. possesses significant advantages in the precision machining of Pure PI (Pure Polyimide), aiming to provide exceptional value to global customers, including wholesale options.

Integrated Solution

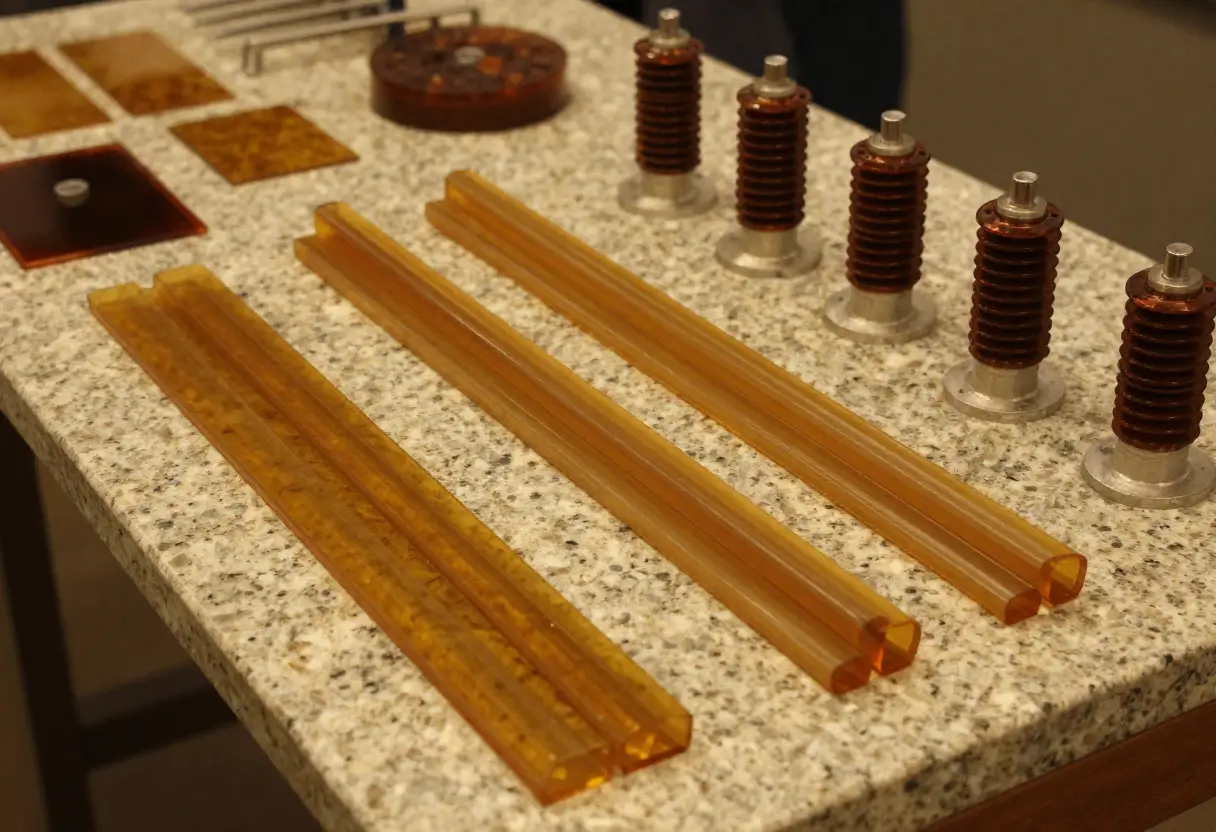

From the supply of Pure PI raw materials (sheets, rods) from our factory to the custom machining of precision components, we offer a complete service chain. Customer procurement processes are simplified, and consistency between material and machining is guaranteed.

Specialized Processing

We have a deep understanding of Pure PI’s unique machining challenges (e.g., material hardness, susceptibility to chipping) and optimized processing techniques. This ensures precise tolerances and high-quality surface finishes, including the exterior of parts.

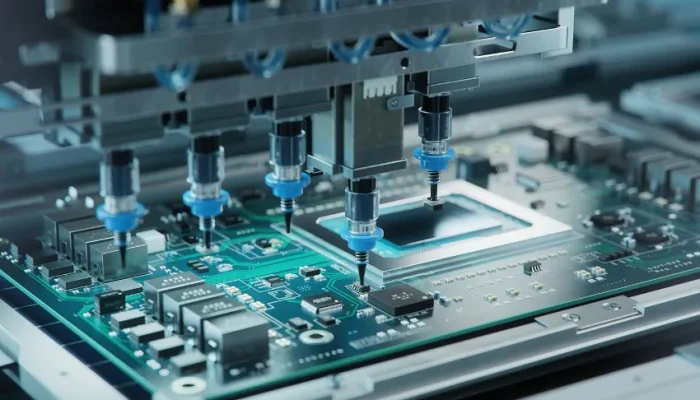

Advanced Equipment

Our company is equipped with precision CNC machine tools, injection molding machines, lathes, and auxiliary equipment suitable for processing high-performance polymers. This allows us to meet complex geometric shapes and stringent design requirements.

Rigorous Quality Control

Over 20 inspection instruments are used for final inspection. From raw materials to finished products, quality at every stage is strictly controlled to ensure parts meet drawing specifications and performance requirements.

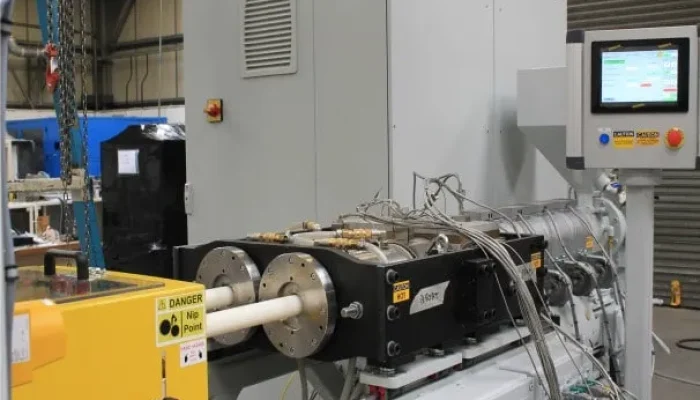

Application Experience

Our experience serving demanding industries such as nuclear power, military, automotive, and electronics has provided us with a profound understanding of Pure PI’s performance and machining considerations in specific applications.

Customization Capability

Whether for small-batch prototype production or large-scale manufacture orders, our flexible production capacity can meet the customized needs of different customers.

Choosing Allstar Material for Pure PI component machining means choosing reliability, precision, and professionalism. We are committed to being your long-term, trustworthy partner in demanding engineering plastics applications. Contact

Applications of Pure PI in Various Industries

Pure PI is widely used in aerospace, electronics, automotive, nuclear, and semiconductor industries for its high heat resistance, electrical insulation, chemical stability, and low outgassing properties, ensuring reliable performance in extreme environments.

Pure Polyimide Resins from Allstar Material

Allstar Material offers a complete range of pure polyimide resins, delivering exceptional performance for advanced engineering applications: