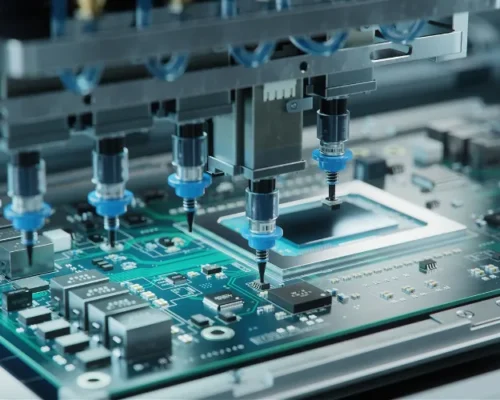

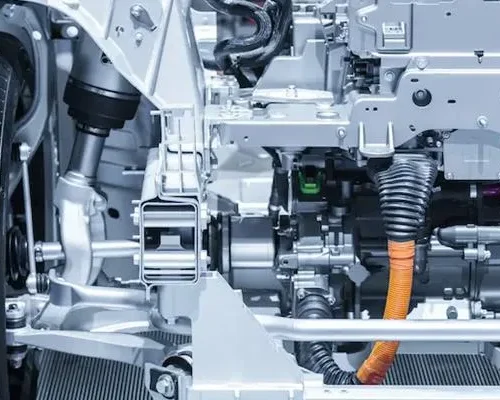

Product Applications

Used to manufacture high temperature resistant seals, wear resistant parts, transmission parts, insulation parts, chip test fixtures and other precision parts. Mainly used in aerospace, semiconductor industry, automobile industry, petroleum industry, special industry and other fields.

Contact Us

Performance Data

Mechanical properties tested at 23°C and 300°C, including hardness, strength, density, and wear resistance using standard methods.

|

Test Features |

Test Method |

Unit |

Test Conditions |

Results |

|---|---|---|---|---|

|

Rockwell Hardness |

GB/T 3398.2-2008 |

HRE |

23°C |

92 |

|

Impact strength of unnotched simply supported beams |

GB/T 1043.1-2008 |

kJ/m² |

23°C |

98 |

|

Flexural Strength |

GB/T 9341-2008 |

MPa |

23°C 300°C |

237 78 |

|

Flexural Modulus |

GB/T 9341-2008 |

MPa |

23°C 300°C |

5119 2417 |

|

Tensile Strength |

GB/T 1040.1-2018 |

MPa |

23°C 300°C |

135 53 |

|

Elongation at break |

GB/T 1040.1-2018 |

% |

23°C 300°C |

7.2 37.1 |

|

Compressive Strength |

GB/T 1041-2008 |

MPa |

1% Deformation 10% Deformation |

22 118 |

|

Poisson's ratio |

ASTM D638-10 |

/ |

23°C |

/ |

|

Surface Resistance |

IEC 61340 |

Ω |

23°C |

10¹⁴-10¹⁵ |

|

Density |

GB/T 1033.1-2008 |

g/cm³ |

23°C |

1.43 |

|

Friction coefficient |

GB/T 3960-2016 |

/ |

2h |

0.15 |

|

Mass of wear |

GB/T 3960-2016 |

mg |

2h |

4 |

|

Absorption |

GB/T 1034-2008 |

% |

24h 48h |

0.11 0.18 |

The above data are product sample measurement values, not guaranteed values; All products are formed by compression, with a certain degree of directionality.