Main Grades and Properties of PEEK Tubes

Pure PEEK Tube

Properties: No reinforcement material, maintaining the base properties of PEEK. It offers excellent mechanical strength, high-temperature resistance (up to 250°C), chemical resistance (acid, alkali, solvent resistance), and electrical insulation.

Applications: Suitable for general industrial applications, electronic devices, medical equipment, aerospace, and other fields.

CF30 PEEK Tube (30% Carbon Fiber Reinforced PEEK)

Properties: Contains 30% carbon fiber reinforcement, significantly enhancing the rigidity, wear resistance, and compressive strength of the PEEK tube. The carbon fiber reinforcement also reduces the thermal expansion coefficient and improves material stability under high load conditions.

Applications: Suitable for high-load, high-pressure environments such as automotive engine components, aerospace structures, and precision mechanical parts.

GF30 PEEK Tube (30% Glass Fiber Reinforced PEEK)

Properties: Contains 30% glass fiber, enhancing the material’s rigidity, strength, and temperature resistance. The glass fiber increases the compressive strength and dimensional stability of the PEEK tube, making it suitable for long-term use at high temperatures.

Applications: Used for components requiring high-temperature resistance, strong rigidity, and the ability to withstand large loads, such as seals, gaskets, and mechanical parts.

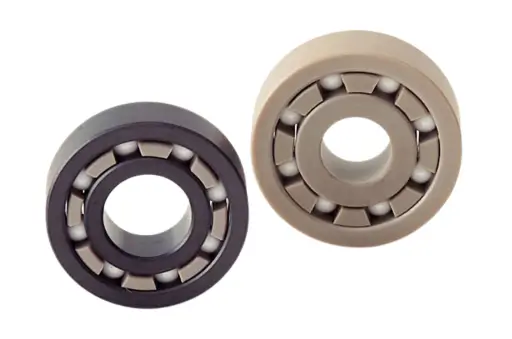

Bearing Grade PEEK (10% Graphite, 10% Carbon Fiber, 10% PTFE Reinforced)

Properties: Self-lubricating, high strength, high-temperature resistance (up to 250°C), excellent wear resistance, and chemical resistance.

Applications: Suitable for high-load, high-temperature, and non-lubricated environments. Widely used in bearings, sliding components, pumps, valves, automation equipment, and industrial parts requiring corrosion resistance and wear resistance.

Properties of Different Grades of PEEK Plates

| Item | Material Grade | |||||

|---|---|---|---|---|---|---|

| Pure PEEK | GF30 PEEK | CF30 PEEK | Bearing grade PEEK | |||

| Test Standard or Instrument | Unit | 100%PEEK | PEEK+30%Glass Fiber | PEEK+30%Carbon Fiber | PEEK+10%Carbon Fiber+10%Graphite+10%PTFE | |

| Tensile strength(23°C) | ISO527 | MPa | 100 | 155 | 220 | 134 |

| Bending strength(23°C) | ISO 178 | MPa | 163 | 212 | 298 | 186 |

| Compressive strength(23°C) | ISO 604 | MPa | 118 | 215 | 240 | 150 |

| Lzod impact strength( no gap) | ISO 180/IU | kJ/m² | No Crack | 51 | 46 | 32 |

| Item | Material Grade | |||||

|---|---|---|---|---|---|---|

| Pure PEEK | GF30 PEEK | CF30 PEEK | Bearing grade PEEK | |||

| Test Standard or Instrument | Unit | 100%PEEK | PEEK+30%Glass Fiber | PEEK+30%Carbon Fiber | PEEK+10%Carbon Fiber+10%Graphite+10%PTFE | |

| Melting point | DSC 11357 | °C | 343 | 343 | 343 | 343 |

| Distortion temperature | ISO 75-1/2 | °C | 163 | 315 | 315 | 293 |

| Continuous using temperature | UL 74685 | °C | 260 | 260 | 260 | 260 |

| Coefficient of thermal expansion | ASTM D696 | 10 -5°C | 4.7 | 2.2 | 1.5 | 2.2 |

| Flammable level | UL 94 | V-0@mm | 1.5 | 1.5 | 1.5 | 0.75 |

| Item | Material Grade | |||||

|---|---|---|---|---|---|---|

| Pure PEEK | GF30 PEEK | CF30 PEEK | Bearing grade PEEK | |||

| Test Standard or Instrument | Unit | 100%PEEK | PEEK+30%Glass Fiber | PEEK+30%Carbon Fiber | PEEK+10%Carbon Fiber+10%Graphite+10%PTFE | |

| Dielectric strength | IEC 60243-1 | kV/mm | 18 | 19 | ||

| Dielectric constant | IEC60250 | – | 3.2 | 3.3 | ||

| Surface resistivity | Ω | 1015 | 1015 | 3*106 | 5*106 | |

| Item | Material Grade | |||||

|---|---|---|---|---|---|---|

| Pure PEEK | GF30 PEEK | CF30 PEEK | Bearing grade PEEK | |||

| 100%PEEK | PEEK+30%Glass Fiber | PEEK+30%Carbon Fiber | PEEK+10%Carbon Fiber+10%Graphite+10%PTFE | |||

| Test Standard or Instrument | Unit | |||||

| Density | ISO 1183 | g/cm³ | 1.3±0.01 | 1.5±0.01 | 1.4±0.01 | 1.43±0.01 |

| Rockwell hardness | ISO 2039 | HRR | 118 | 119 | 121 | 108 |

| Friction coefficient | μ | 0.30-0.38 | 0.38-0.46 | 0.28 | 0.18 | |

| Water Abs. (25°C.24Hrs) | ISO 62 | % | 0.5 | 0.11 | 0.06 | 0.06 |

| Mould shrinking percentage | 3mm,170°C, Flow direction | % | 1.2 | 0.4 | 0.1 | 0.3 |

| Perpendicular to flow direction | % | 1.5 | 0.8 | 0.5 | 0.5 | |

Allstar Material PEEK tubes stock specifications

Standard Size Ranges Available:

- Outer Diameter: 20-300mm (stock sizes)

- Inner Diameter: 12-280mm

- Wall Thickness: 2-50mm

- Standard Length: 3000mm (custom lengths available)

Machining Methods for Allstar Material PEEK Rods

Extrusion

Extrusion became our go-to process after we solved the dimensional consistency challenges that plagued our early attempts. The breakthrough came when we realized that PEEK's narrow processing window required much tighter temperature control than our original equipment could provide.

Compression Molding

We developed compression molding capabilities after customers began requesting tube sizes that were impossible to extrude consistently. Large diameter tubes (>200mm OD) and thick-wall applications pushed us beyond extrusion's practical limits.

Injection Molding

Our injection molding capability evolved from customer requests for tubes with integrated features - flanges, threads, or stepped diameters that would require expensive secondary operations if made from extruded tube stock.