Feature Analysis of PEEK Films

High Temperature Resistance

Can withstand temperatures from lead-free soldering processes. The film thickness ranges from 25 to 155 microns. For mechanical applications without impact, the RTI (Relative Thermal Index) is 220°C, and for electrical applications, it is 200°C. It remains stable up to 500°C at its carbonization point.

Excellent Mechanical Properties:

A balanced plastic film with both toughness and rigidity, particularly outstanding in fatigue resistance under alternating stresses, making it comparable to alloy materials.

Chemical Resistance:

Exhibits excellent chemical resistance. Among typical chemicals, only concentrated sulfuric acid can dissolve or destroy it. Its corrosion resistance is similar to nickel steel.

Self-Lubricating Properties:

Outstanding sliding characteristics among all plastic films, ideal for applications requiring low friction coefficients and wear resistance. PEEK films modified with a mix of carbon fiber and graphite exhibit enhanced self-lubricating properties.

Radiation Resistance:

Has strong resistance to high radiation doses, maintaining excellent insulating properties even under extreme irradiation levels.

High Sound Clarity:

Avoids ""auditory fatigue"" caused by metallic film noise, providing better acoustic performance.

Hydrolysis Resistance:

Not affected by water or high-pressure steam. Products made from this film material can retain excellent properties even in high-temperature, high-pressure water environments.

Melt Processing Capability:

When heated above its melting point, it integrates with metals. Ultrasonic sealing is easy (similar to PET films). Laser welding and printing are also possible.

Flame Retardancy:

An extremely stable polymer that achieves the highest flame-retardant standards without adding any flame retardants. It is halogen-free and meets IEC 61249-2-21 standards.

Performance table of PEEK film produced by Allstar Material

| Item | Material Grade | |||||

|---|---|---|---|---|---|---|

| Pure PEEK | GF30 PEEK | CF30 PEEK | Bearing grade PEEK | |||

| Test Standard or Instrument | Unit | 100% PEEK | PEEK + 30% Glass Fiber | PEEK + 30% Carbon Fiber | PEEK + 10% Carbon Fiber + 10% Graphite + 10% PTFE | |

| Tensile strength (23°C) | ISO 527 | MPa | 100 | 155 | 220 | 134 |

| Bending strength (23°C) | ISO 178 | MPa | 163 | 212 | 298 | 186 |

| Compressive strength (23°C) | ISO 604 | MPa | 118 | 215 | 240 | 150 |

| Izod impact strength (no gap) | ISO 180/IU | kJ/m² | No Crack | 51 | 46 | 32 |

Allstar Materials peek films stock

| Thickness (mm) | Width (mm) | Approx. Weight per Meter (g/m)* |

|---|---|---|

| 0.03 | 600 | 23.6 |

| 0.05 | 600 | 39.3 |

| 0.075 | 600 | 59 |

| 0.1 | 600 | 78.6 |

| 0.125 | 600 | 98.3 |

| 0.15 | 600 | 117.9 |

| 0.2 | 600 | 157.2 |

| 0.25 | 600 | 196.5 |

| 0.3 | 600 | 235.8 |

| 0.4 | 600 | 314.4 |

| 0.5 | 600 | 393 |

| 0.75 | 600 | 589.5 |

| 1 | 600 | 786 |

| 1.5 | 600 | 1179 |

| 2 | 600 | 1572 |

| 2.5 | 600 | 1965 |

| 3 | 600 | 2358 |

- 0.03–0.1mm: Ideal for flexible electronics and precision insulation

- 0.125–0.5mm: Perfect for acoustic diaphragms and sealing applications

- 0.75–3mm: Designed for structural applications and thick insulation barriers

Main Grades and Properties of PEEK Tubes

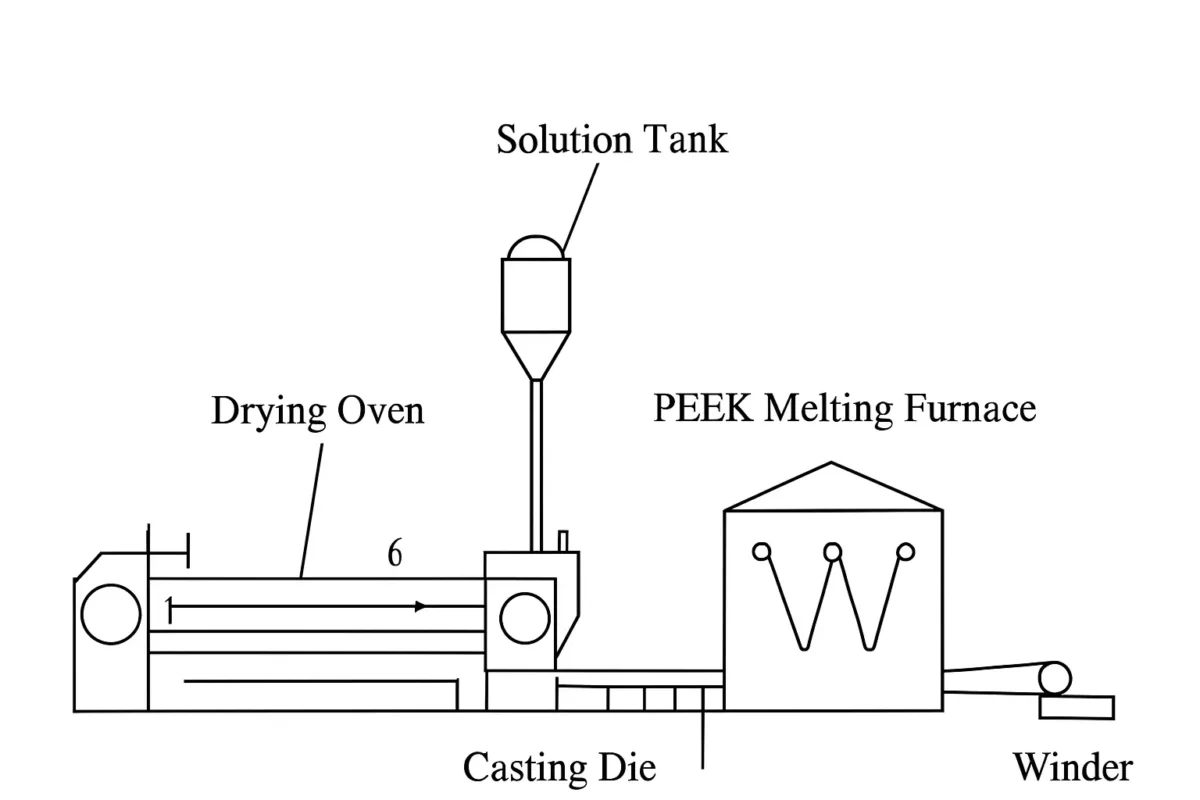

Basic Steps of the Casting Process:

Resin Melting: First, PEEK resin is heated to its molten state, typically around 350°C. It is important to ensure the PEEK resin is completely melted to ensure uniform flow and film formation.

Extrusion: The molten PEEK resin is extruded through an extruder and passed through a flat die (also known as a casting die) to form a film. During this process, the PEEK resin is stretched into film form on the casting die.

Cooling and Solidifying: The film is quickly cooled by a cooling roller or water-cooling system, causing the molten PEEK resin to cool and solidify into film form.

Winding: The cooled PEEK film is wound into rolls for subsequent processing, transportation, and use.

Advantages of the Casting Process:

High Precision Films:

The casting process produces films with uniform thickness and smooth surfaces, making it suitable for high-demand applications.”

Higher Production Efficiency:

This process is ideal for large-scale production and is suitable for high-performance polymers like PEEK.

Customizability:

By adjusting parameters such as temperature and stretching speed, various film properties like thickness, hardness, and transparency can be tailored.