Detailed Advantages of PEEK Injection Molding

Large-Scale Efficient Production

Injection molding is a highly automated, short-cycle manufacturing method that enables large-scale, efficient production of complex-shaped parts.

High Precision and Complexity

PEEK injection molding can produce parts with extremely high precision and complex geometries, reducing the need for secondary processing, thereby lowering overall costs.

Consistency and Repeatability

The injection molding process uses molds, ensuring that the size and performance of each part are highly consistent, which is critical for mass production.

Cost-Effectiveness

Injection molding reduces material waste and enables large-scale production, which lowers the unit cost of each part, especially when compared to machined parts.

Customizable Design

Injection molding molds can be designed to meet specific customer requirements, enabling highly customized products to meet a wide range of unique application scenarios.

Disadvantages of PEEK Injection Molding

High Mold Investment, Low Quantity Unit Cost

PEEK Injection Molding Process Introduction by Allstar Material

Preparation of Raw Materials

Choose the appropriate PEEK material pellets, dry at 160°C high temperature. The drying time depends on the material humidity and ambient air humidity.

Injection Molding Equipment Setup

PEEK injection molding requires a high-temperature injection molding machine capable of withstanding higher melt temperatures (typically 380°C-400°C). Adjust the temperature of the screw and heating zones to meet the high-temperature requirements of PEEK, ensuring smooth melting of the material.

Injection Molding Process Parameters

Melt Temperature: The melt temperature for PEEK usually ranges from 340°C to 380°C, with slight adjustments based on the material and product requirements.

Injection Pressure: Due to the high viscosity of PEEK, injection pressure is generally high, usually between 1000 and 1500 bar.

Injection Speed: Control the injection speed to ensure uniform filling of the mold, avoiding bubbles and defects.

Holding Pressure: After injection, maintain a certain pressure to ensure the mold is completely filled, ensuring the final product’s density and surface finish.

Cooling and Demolding

Cooling Time: Due to PEEK’s poor thermal conductivity, cooling time is relatively long. The cooling time depends on the mold thickness and part shape, usually ranging from 30 to 90 seconds.

Demolding: After cooling, open the mold and remove the formed PEEK part. PEEK injection molded parts typically have high dimensional accuracy and smooth surfaces.

Post-Processing and Finishing

Deburring and Polishing: Post-molding parts typically need deburring to ensure smooth edges.

Surface Treatment: In high-demand applications, PEEK injection molded parts may require surface coatings, spraying, or other treatments to enhance wear resistance, corrosion resistance, or appearance.

PEEK Injection Molding Precautions

Equipment: Standard injection molding machines can be used, but since the processing temperature for PEEK reaches 350-400°C, it is recommended to use ceramic heating bands and barrel insulation sleeves. The screw should be of a universal type, and copper or copper alloys should be avoided.

Drying: PEEK pellets must be dried before processing to ensure the residual moisture content is below 0.02%. A circulating oven or dehumidifying dryer can be used for drying.

Cleanliness: Since most other polymers degrade at PEEK’s processing temperature, contamination must be avoided. All equipment must be thoroughly cleaned, and it is recommended to use dedicated equipment for recycling material.

Gate Design: To ensure the components are fully filled, large gates should be used as much as possible, as PEEK has a high shrinkage rate. The gate size and design should be selected based on the component’s maximum cross-sectional thickness and geometry.

Temperature Control: Proper mold temperature control is critical to ensure that PEEK components maintain a semi-crystalline state, allowing it to exhibit its unique properties. The mold surface temperature should be kept between 170-200°C.

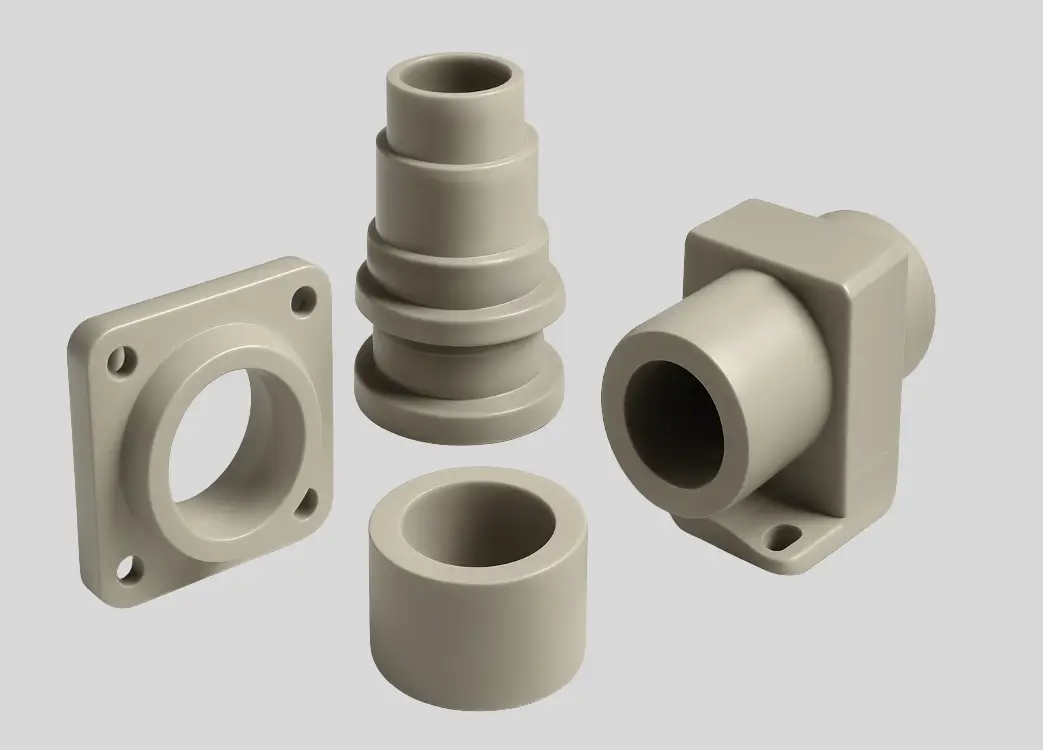

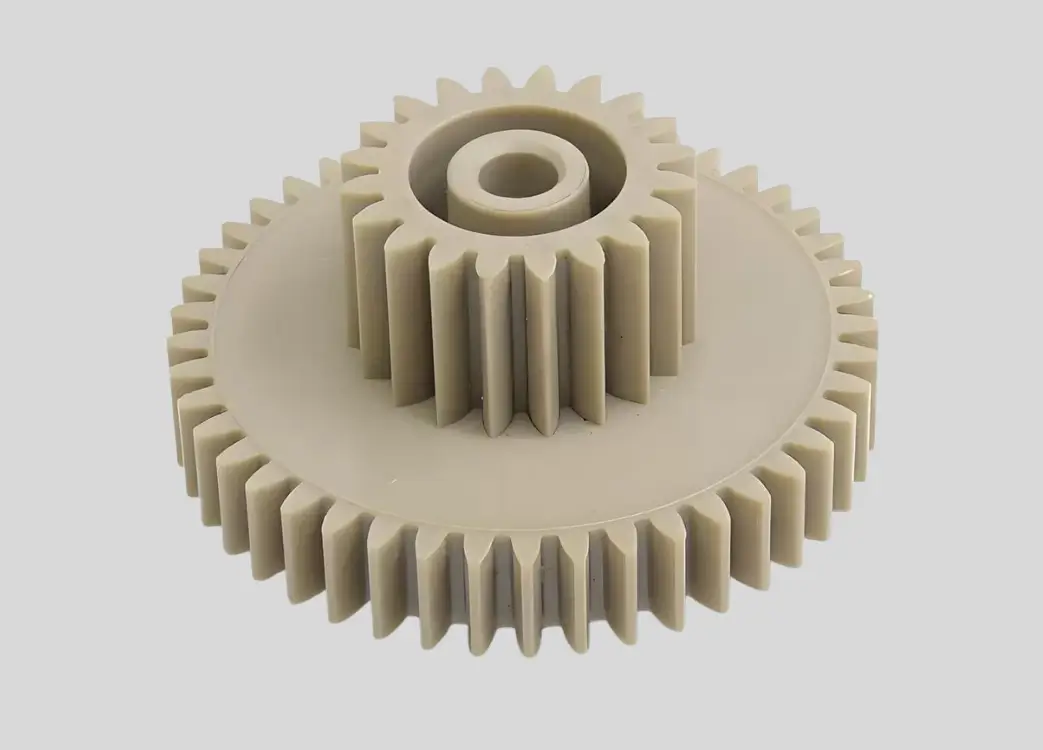

PEEK Injection Molding Products Display