What is CF30 PEEK?

| Feature | Bearing Grade PEEK | Virgin PEEK | CF30 PEEK (30% Carbon Fiber) | GF30 PEEK (30% Glass Fiber) |

|---|---|---|---|---|

| Color | Black or Dark Gray | Natural (off-white, beige) | Black | Beige / Light Brown |

| Surface Finish | Self-lubricating, low friction | Glossy, smooth | Matte, carbon fiber rich | Slightly rough/Matte |

| Density (g/cm³) | 1.43±0.01 | 1.3±0.01 | 1.4±0.01 | 1.5±0.01 |

| Wear Resistance | Excellent | Good | High | High |

| Friction Coefficient (μ) | 0.18 | 0.30–0.38 | 0.28 | 0.38–0.46 |

| Electrical Properties | Insulating | Insulating | Conductive | Insulating |

| Machinability | Good | Excellent | Good | Moderate |

Comparison of Pure PEEK vs Filled PEEK

Pure PEEK vs Glass Fiber Reinforced PEEK:

Pure PEEK: Offers the highest toughness and elongation, better fatigue resistance.

Glass Fiber Reinforced

PEEK: Provides higher rigidity and strength, reduces thermal expansion.

Pure PEEK vs Carbon Fiber Reinforced PEEK:

Pure PEEK: Better ductility and impact toughness.

Carbon Fiber ReinforcedPEEK: Higher compressive strength and conductivity.

Pure PEEK vs PTFE Filled PEEK:

Pure PEEK: Higher mechanical strength.

PTFE Filled PEEK: Lower friction coefficient and better wear resistance.

Pure PEEK Quality Certifications

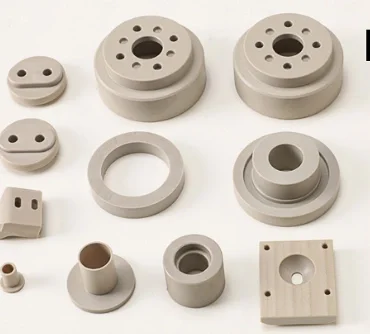

Applications of Pure PEEK

Applications of Pure PEEK

| Peek Plates/sheets: | |

| Thickness: | 4 – 120 mm |

| Max. Width: | 600 mm |

| Length: | 1000 – 3000 mm |

| Peek Rods: | |

| Diameter: | 5 – 200 mm |

| Length: | 1000 – 3000 mm |

| Peek Tubes: | |

| Inner Diameter (ID): | 12 – 400 mm |

| Outer Diameter (OD): | 23 – 450 mm |

| Length: | Custom (Per customer requirements) |

| Peek Films: | |

| Thickness: | 0.03 – 3 mm |

| Max. Width: | 600 mm |

| Peek Capillary Tubes: | |

| Inner Diameter (ID): | 0.3 – 7.9 mm |

| Outer Diameter (OD): | 0.5 – 8.2 mm |

| Format: | Supplied in Coils / On Spools |

| Peek Filaments: | |

| Diameter: | 0.008 – 3 mm |