A-PI-380 Polyimide

A-PI-380 is a high-performance polyimide resin, the product has advantages such as high temperature resistance, high insulation, self-lubricating, low friction coefficient, low dielectric constant, chemical resistance, radiation resistance, heat deformation resistance, high mechanical strength, and good machining performance.

Product Applications

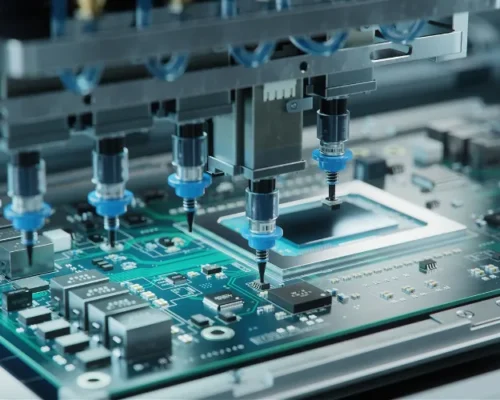

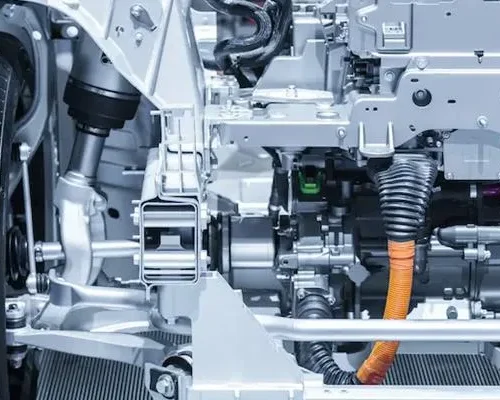

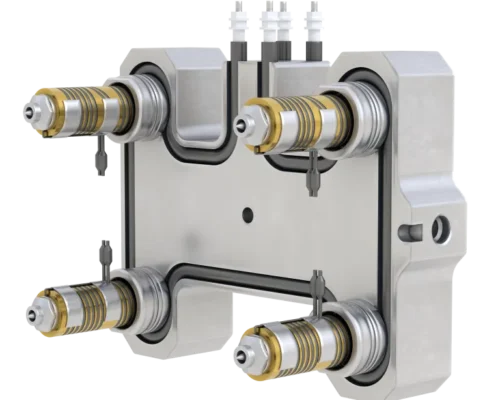

Used for manufacturing components such as high and low temperature resistant parts, wear-resistant parts, insulation parts, oil-free bearings, valve seats, seals, chip test bases, etc. The product is widely used in aerospace, semiconductor industry, automotive industry, hot runner and other fields.

Contact Us

Performance Data

Mechanical properties tested at 23°C and 260°C, including hardness, strength, density, and wear resistance using standard methods.

|

Test Features |

Test Method |

Unit |

Test Conditions |

Results |

Competitor 1 |

Competitor 2 |

|---|---|---|---|---|---|---|

|

Rockwell Hardness |

GB/T 3398.2-2008 |

HRE |

23°C |

51 |

45 |

46 |

|

Impact strength of unnotched simply supported beams |

GB/T 1043.1-2008 |

kJ/m² |

23°C |

65 |

73 |

49 |

|

Flexural Strength |

GB/T 9341-2008 |

MPa |

23°C 260°C |

112 65 |

110 62 |

113 59 |

|

Flexural Modulus |

GB/T 9341-2008 |

MPa |

23°C 260°C |

3031 1886 |

3100 1724 |

3040 1667 |

|

Tensile Strength |

GB/T 1040.1-2018 |

MPa |

23°C 260°C |

82 42 |

86 41 |

88 41 |

|

Elongation at break |

GB/T 1040.1-2018 |

% |

23°C 260°C |

7.8 6.7 |

7.5 7 |

8 6 |

|

Compressive Strength |

GB/T 1041-2008 |

MPa |

1% Deformation 10% Deformation |

26 129 |

24 133 |

24 128 |

|

Coefficient of thermal expansion |

ASTM D-696 |

µm/m/k |

296~573K |

54 |

54 |

55 |

|

Shear Strength |

HG/T 3839-2006 |

MPa |

23°C |

91 |

89 |

/ |

|

Poisson's ratio |

ASTM D638-10 |

/ |

23°C |

0.43 |

0.41 |

0.37 |

|

Surface Resistance |

IEC 61340 |

Ω |

23°C |

>10¹² |

>10¹² |

>10¹² |

|

Density |

GB/T 4472-2011 |

g/cm³ |

23°C |

1.43 |

1.43 |

1.38 |

|

Friction coefficient |

GB/T 3960-2016 |

/ |

2h |

0.27 |

0.29 |

0.32 |

|

Mass of wear |

GB/T 3960-2016 |

mg |

2h |

4.2 |

7.6 |

/ |

|

Absorption |

GB/T 1034-2008 |

% |

24h 48h |

0.18 0.31 |

0.23 0.32 |

0.21 0.5 |

The above data are product sample measurement values, not guaranteed values; All products are formed by compression, with a certain degree of directionality.