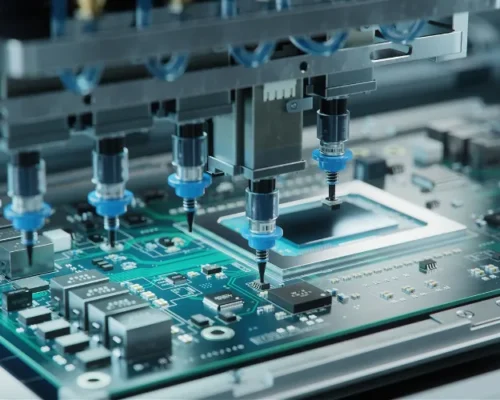

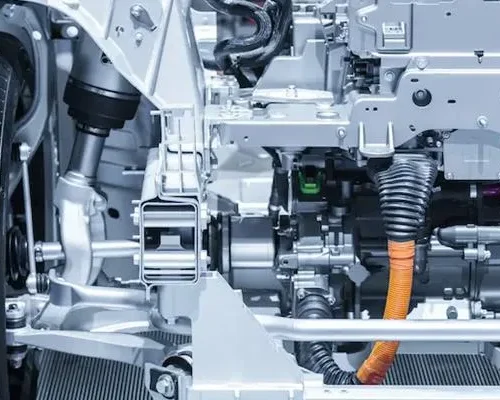

Product Applications

Used for manufacturing high and low temperature resistant parts, insulation parts, oil-free bearings, shaft sleeves, etc. The product is widely used in fields such as aerospace, semiconductor industry, and automotive industry.

Contact Us

Performance Data

Mechanical properties tested at 23°C and 260°C, including hardness, strength, density, and wear resistance using standard methods.

|

Test Features |

Test Method |

Unit |

Test Conditions |

Results |

|---|---|---|---|---|

|

Rockwell Hardness |

GB/T 3398.2-2008 |

HRE |

23°C |

86 |

|

Impact strength of unnotched simply supported beams |

GB/T 1043.1-2008 |

kJ/m² |

23°C |

73 |

|

Flexural Strength |

GB/T 9341-2008 |

MPa |

23°C 260°C |

207 96 |

|

Flexural Modulus |

GB/T 9341-2008 |

MPa |

23°C 260°C |

4314 2653 |

|

Tensile Strength |

GB/T 1040.1-2018 |

MPa |

23°C 260°C |

138 50 |

|

Elongation at break |

GB/T 1040.1-2018 |

% |

23°C 260°C |

9.5 14 |

|

Compressive Strength |

GB/T 1041-2008 |

MPa |

1% Deformation 5% Deformation |

32 169 |

|

Coefficient of thermal expansion |

ASTM D-696 |

µm/m/k |

296~573K |

58 |

|

Shear Strength |

HG/T 3839-2006 |

MPa |

23°C |

124 |

|

Poisson's ratio |

ASTM D638-10 |

/ |

23°C |

0.32 |

|

Surface Resistance |

IEC 61340 |

Ω |

23°C |

>10¹² |

|

Density |

GB/T 4472-2011 |

g/cm³ |

23°C |

1.39 |

|

Friction coefficient |

GB/T 3960-2016 |

/ |

2h |

0.17 |

|

Mass of wear |

GB/T 3960-2016 |

mg |

2h |

3.3 |

|

Absorption |

GB/T 1034-2008 |

% |

24h 48h |

0.11 0.21 |

The above data are product sample measurement values, not guaranteed values; All products are formed by compression, with a certain degree of directionality.