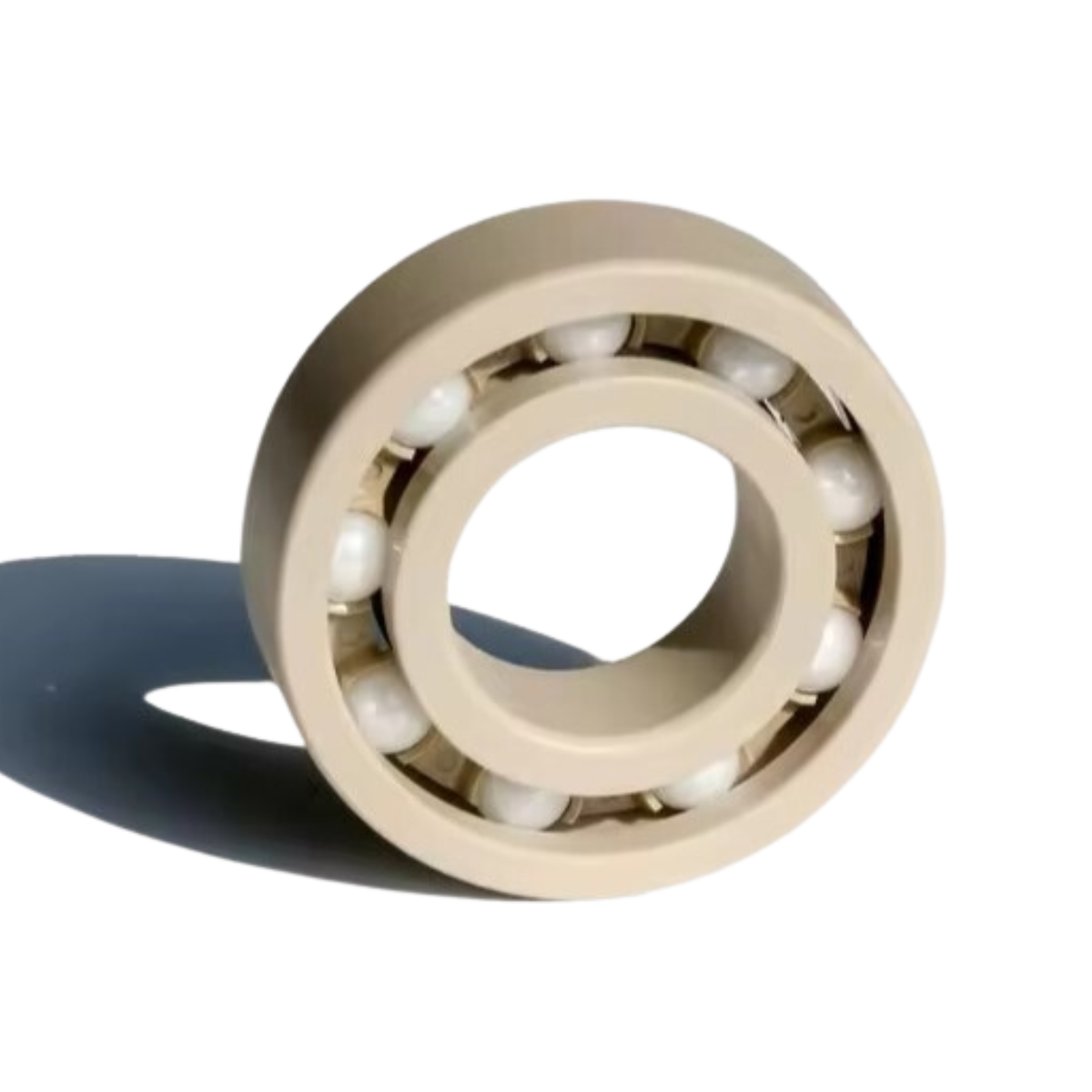

Performance Table of Bearing Grade PEEK

Mechanical Behavior

| Item | Tensile strength(23℃) | Bending strength(23℃) | Compressive strength(23℃) | Lzod impact strength(no gap) | ||

|---|---|---|---|---|---|---|

| ISO527 | ISO 178 | ISO 604 | ISO 180/IU | |||

| Test Standard or Instrument | Unit | MPa | MPa | MPa | kJ/m² | |

| PEEK+10%Carbon Fiber+10%Graphite+10%PTFE | 134 | 186 | 150 | 32 |

Thermal Performance

| Item | Melting point | Distortion temperature | Continuous using temperature | Coefficient of thermal expansion | Flammable level | ||

|---|---|---|---|---|---|---|---|

| DSC 11357 | ISO 75-1/2 | UL 74685 | ASTM D696 | UL 94 | |||

| Test Standard or Instrument | Unit | ℃ | ℃ | ℃ | 10 -5℃ | V-0@mm | |

| PEEK+10%Carbon Fiber+10%Graphite+10%PTFE | 343 | 293 | 260 | 2.2 | 0.75 |

Electrical Performance

| Item | Dielectric strength | Dielectric constant | Surface resistivity | ||

|---|---|---|---|---|---|

| IEC 60243-1 | IEC60250 | ||||

| Test Standard or Instrument | Unit | kV/mm | – | Ω | |

| PEEK+10%Carbon Fiber+10%Graphite+10%PTFE | 5*106 |

Other Performance

| Item | Density | Rockwell hardness | Friction coefficient | Water Abs. (25°C.24Hrs) | Mould shrinking percentage | |||

|---|---|---|---|---|---|---|---|---|

| ISO 1183 | ISO 2039 | ISO 62 | 3mm,170 ℃, Flow direction | Perpendicular to flow direction | ||||

| Test Standard or Instrument | Unit | g/cm³ | HRR | μ | % | % | % | |

| PEEK+10%Carbon Fiber+10%Graphite+10%PTFE | 1.43±0.01 | 108 | 0.18 | 0.06 | 0.3 | 0.5 | ||

Differences Between Various Grades of PEEK Materials and Their Typical Applications

| Property | Bearing Grade PEEK | Virgin PEEK | CF30 PEEK (30% Carbon Fiber) | GF30 PEEK (30% Glass Fiber) |

|---|---|---|---|---|

| Main Function | Wear resistance, low friction | High toughness, high purity | High strength, high stiffness, conductivity | High strength, high stiffness, high heat resistance |

| Core Filler | 10% PTFE, 10% graphite, 10% carbon fiber | None | 30% carbon fiber | 30% glass fiber |

| Advantages | Extremely low friction coefficient, excellent wear resistance, self-lubricating | Highest toughness and ductility, excellent impact resistance, good biocompatibility | Maximum mechanical strength and stiffness, creep resistance, conductive | High mechanical strength, excellent dimensional stability, superior heat resistance |

| Disadvantages | Lower mechanical strength than reinforced PEEK | Relatively high friction coefficient, lower wear resistance | Lower toughness, more brittle than virgin PEEK | Lower toughness, abrasive to tools, electrically insulating |

| Typical Applications | Bearings, bushings, seals, piston rings | Medical implants, food processing parts, high-impact components | Aerospace structures, semiconductor fixtures, automotive high-load parts | Industrial gears, high-load structural parts, pump and valve components |