PEEK + 30% Carbon Fiber

Technical Specifications & Performance Data

Mechanical Behavior

| Item | Tensile Strength (23°C) | Bending Strength (23°C) | Compressive Strength (23°C) | Izod Impact Strength (no gap) |

|---|---|---|---|---|

| Test Standard or Instrument | ISO527 | ISO 178 | ISO 604 | ISO 180/1U |

| Unit | MPa | MPa | MPa | kJ/m² |

| PEEK+30%Carbon Fiber | 220 | 298 | 240 | 46 |

Thermal Performance

| Item | Melting Point | Distortion Temperature | Continuous Using Temperature | Coefficient of Thermal Expansion | Flammability Level |

|---|---|---|---|---|---|

| Test Standard or Instrument | DSC 11357 | ISO 75-1/2 | UL 74685 | ASTM D696 | UL 94 |

| Unit | °C | °C | °C | 10⁻⁵C | V-0@mm |

| PEEK+30%Carbon Fiber | 343 | 315 | 260 | 1.5 | 1.5 |

Electrical Performance

| Item | Dielectric Strength | Dielectric Constant | Surface Resistivity |

|---|---|---|---|

| Test Standard or Instrument | IEC 60243-1 | IEC60250 | — |

| Unit | kV/mm | — | Ω |

| PEEK+30%Carbon Fiber | — | — | 3×10⁵ |

Other Performance

| Item | Density | Rockwell Hardness | Friction Coefficient | Water Abs. (25°C, 24Hrs) | Mould Shrinking Percentage (3mm, 170°C, Flow direction) | Mould Shrinking Percentage (Perpendicular to flow direction) |

|---|---|---|---|---|---|---|

| Test Standard or Instrument | ISO 1183 | ISO 2039 | — | ISO 62 | — | |

| Unit | g/cm³ | HRR | μ | % | % | % |

| PEEK+30%Carbon Fiber | 1.4±0.01 | 121 | 0.28 | 0.06 | 0.1 | 0.5 |

Note: All values are typical properties and may vary depending on specific processing conditions and testing methods. Please consult with technical support for application-specific requirements.

What is CF30 PEEK?

CF30 PEEK vs. unfilled PEEK:

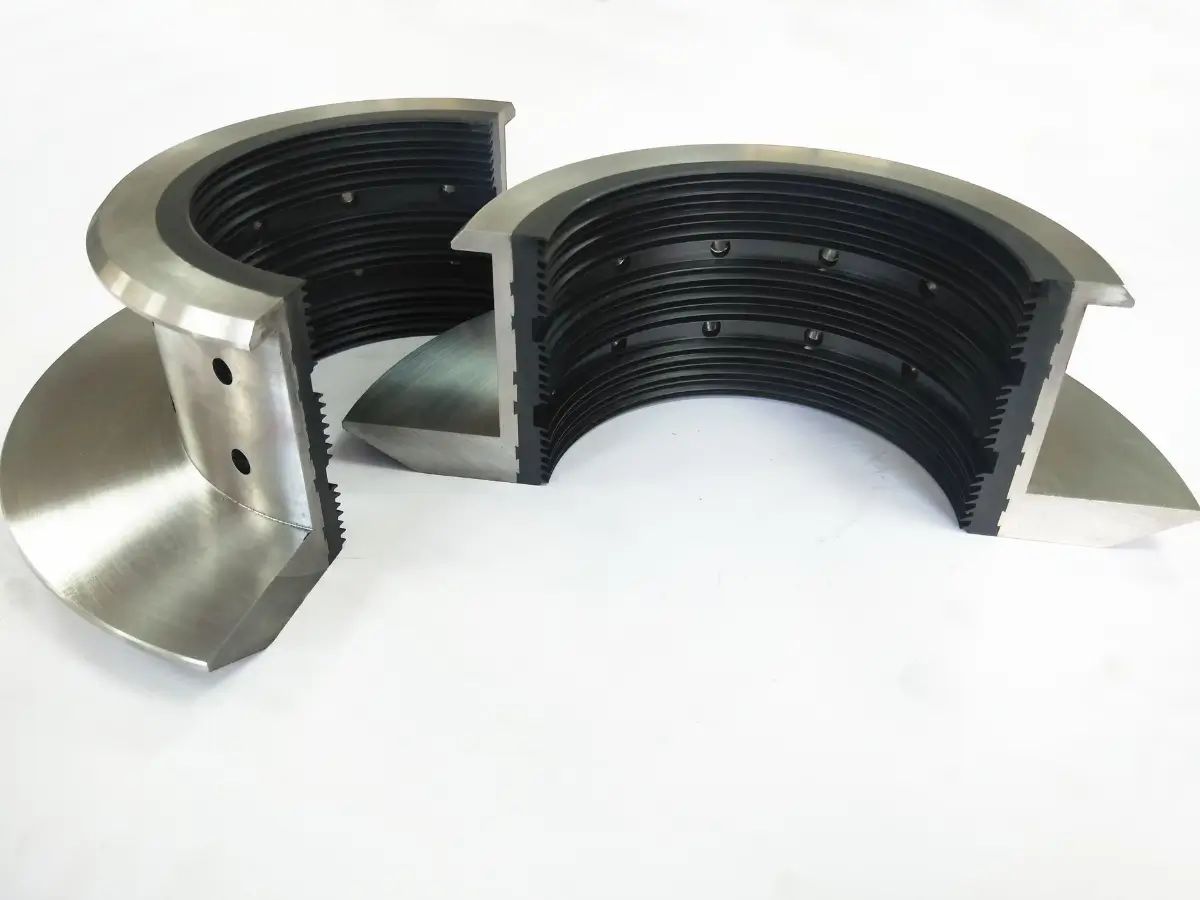

Compared to virgin PEEK, CF30 PEEK sacrifices some toughness but provides significantly higher strength, stiffness, and wear resistance, making it better suited for demanding structural and tribological applications.

CF30 PEEK vs. Glass Fiber Reinforced PEEK:

While both materials improve strength and dimensional stability, CF30 PEEK generally offers higher strength and stiffness, along with the unique benefit of electrical conductivity, which GF30 PEEK lacks.

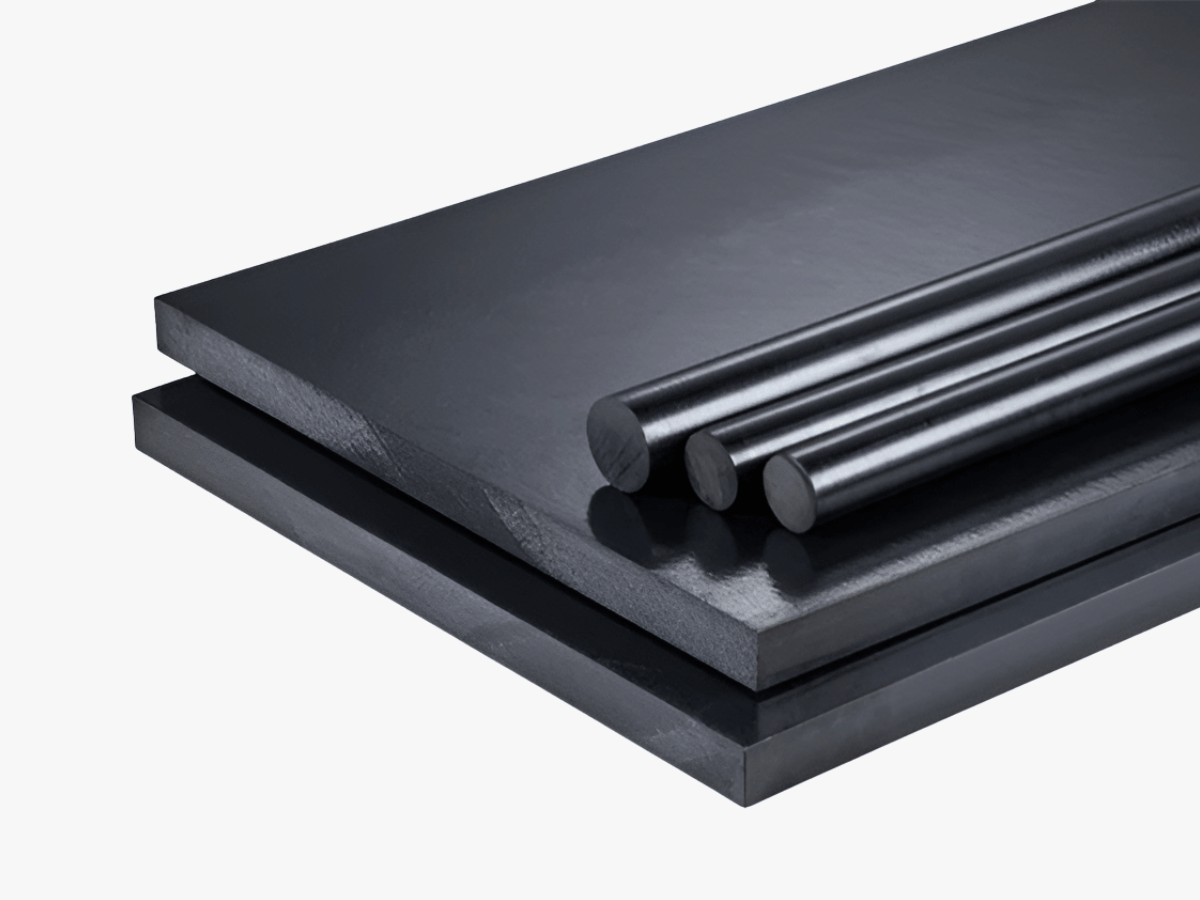

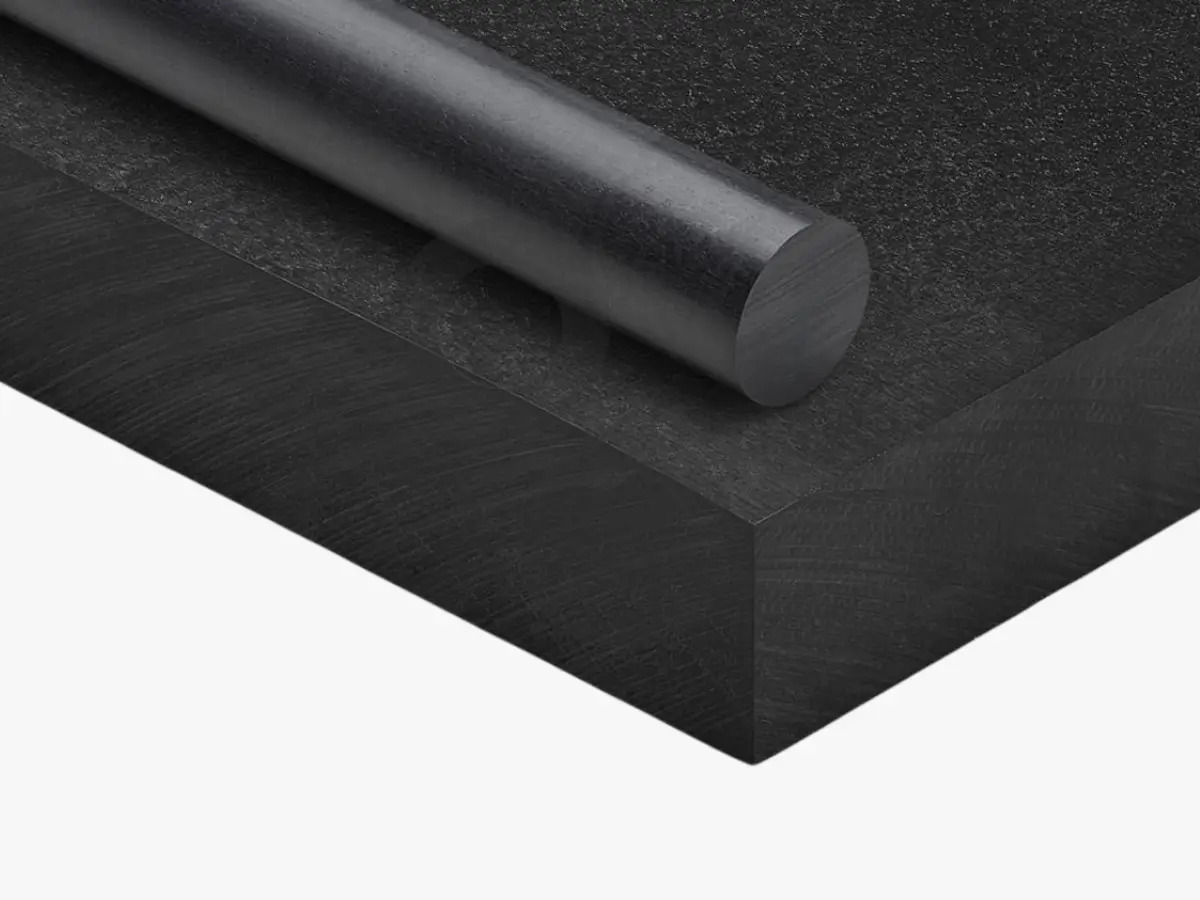

Product Forms and Specifications Available

Peek Tubes:

- Inner Diameter (ID): 12 - 400 mm

- Outer Diameter (OD): 23 - 450 mm

- Length: Custom (Per customer requirements)