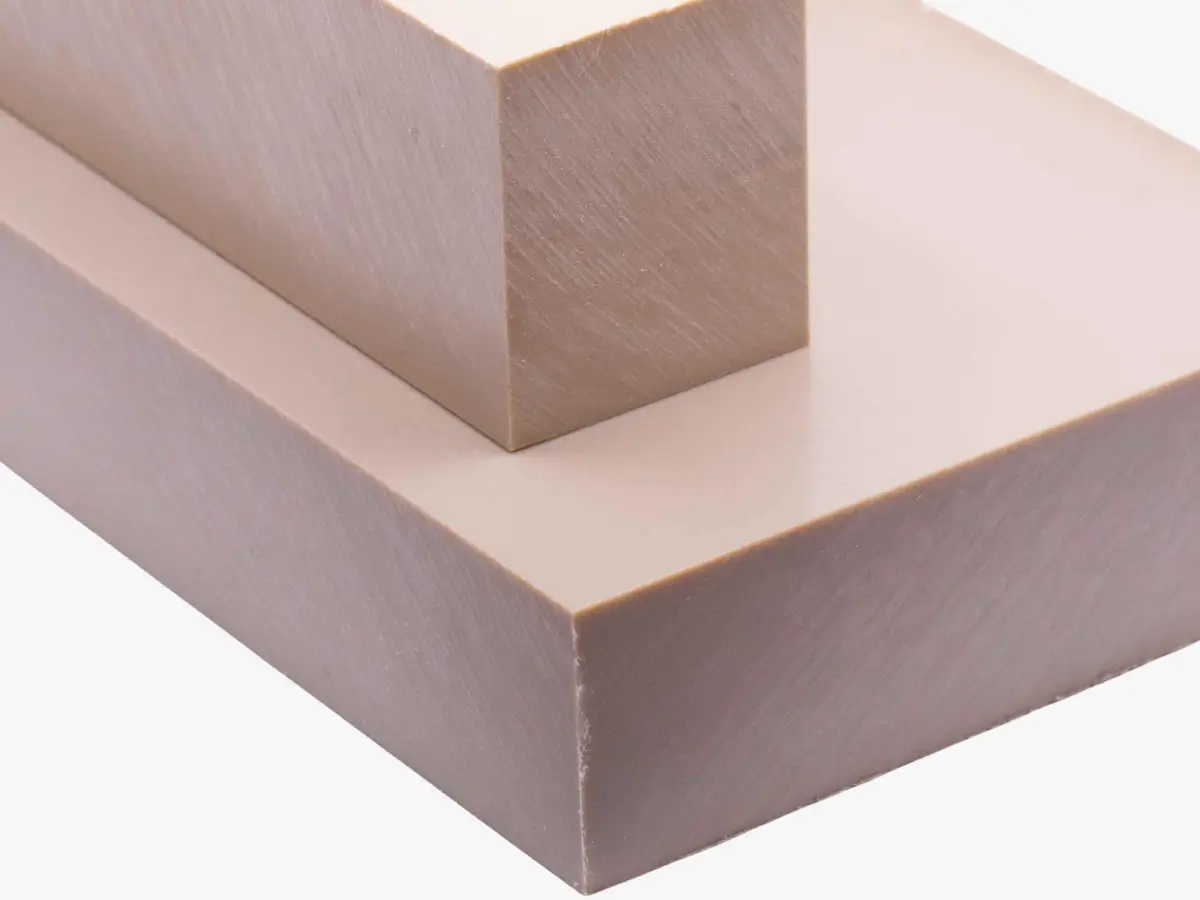

GF30 PEEK + 30% Glass Fiber

Technical Specifications & Performance Data

Mechanical Behavior

| Item | Tensile Strength (23°C) | Bending Strength (23°C) | Compressive Strength (23°C) | Izod Impact Strength (no gap) |

|---|---|---|---|---|

| Test Standard or Instrument | ISO527 | ISO 178 | ISO 604 | ISO 180/IU |

| Unit | MPa | MPa | MPa | kJ/m² |

| PEEK+30%Glass Fiber | 155 | 212 | 215 | 51 |

Thermal Performance

| Item | Melting Point | Distortion Temperature | Continuous Using Temperature | Coefficient of Thermal Expansion | Flammability Level |

|---|---|---|---|---|---|

| Test Standard or Instrument | DSC 11357 | ISO 75-1/2 | UL 74685 | ASTM D696 | UL 94 |

| Unit | °C | °C | °C | 10 -5°C | V-0@mm |

| PEEK+30%Glass Fiber | 343 | 315 | 260 | 2.2 | 1.5 |

Electrical Performance

| Item | Dielectric Strength | Dielectric Constant | Surface Resistivity |

|---|---|---|---|

| Test Standard or Instrument | IEC 60243-1 | IEC60250 | — |

| Unit | kV/mm | – | Ω |

| PEEK+30%Glass Fiber | 19 | 3.3 | 1015 |

Other Performance

| Item | Density | Rockwell Hardness | Friction Coefficient | Water Abs. (25°C, 24Hrs) | Mould Shrinking Percentage (3mm, 170°C, Flow direction) | Mould Shrinking Percentage (Perpendicular to flow direction) |

|---|---|---|---|---|---|---|

| Test Standard or Instrument | ISO 1183 | ISO 2039 | — | ISO 62 | — | |

| Unit | g/cm³ | HRR | μ | % | % | % |

| PEEK+30%Glass Fiber | 1.5±0.01 | 119 | 0.38-0.46 | 0.11 | 0.4 | 0.8 |

Note: All values are typical properties and may vary depending on specific processing conditions and testing methods. Please consult with technical support for application-specific requirements.

GF30 PEEK Comparative Table

Comparison with Other PEEK Grades

GF30 PEEK vs. Other PEEK Grades

| Comparison | GF30 PEEK (30% Glass Fiber Reinforced PEEK) | Virgin PEEK | CF30 PEEK (30% Carbon Fiber Reinforced PEEK) | Bearing Grade PEEK |

|---|---|---|---|---|

| Reinforcement | 30% glass fiber | None | 30% carbon fiber | 10% PTFE, 10% graphite, 10% carbon fiber |

| Strength & Stiffness | Very high | Moderate | High, slightly lower than GF30 | Moderate |

| Heat Resistance | High heat deflection temperature | Moderate | High | Moderate |

| Toughness | Reduced, more brittle | Very high | Moderate | Moderate |

| Wear Resistance | Moderate, may abrade mating surfaces | Low | High | Excellent |

| Electrical Conductivity | Electrically insulating | Insulating | Conductive | Insulating |

| Ideal Applications | High-load structural components | General-purpose parts | Aerospace, automotive high-load parts, conductive applications | Bearings, bushings, sliding or friction parts |

Typical Applications of PEEK in Various Industries

Electronics Industry

- Connectors: Electronic connectors for high-temperature, high-frequency, and high-voltage environments environments

- Semiconductor Equipment: Components for wafer processing equipment and test probe holders

- Electronic Components: Insulators, relay housings, and integrated circuit carriers

Aerospace Industry

- Structural Components: Aircraft interior parts and seat assemblies

- Engine Components: Turbine blades, sealing rings

- Electronic Systems: Avionics housings, radar modules

Automotive Industry

- Engine Systems: Piston rings, bearing cages

- Turbochargers: Impellers, housing components

- Brake Systems: Brake pad backplates, brake components

Oil & Gas / Petrochemical Industry

- Sealing Components: High-temperature, high-pressure valve seals

- Turbochargers: Impellers, housing components

- Pipeline Connections: Flanges, fittings

Medical Devices

- Implants: Spinal fusion devices, artificial joints

- Surgical Instruments: Endoscope components, minimally invasive surgical tools

- Medical Equipment: Dialysis machine parts, blood analyzer components