Allstar Material Modified Polyimide PI Performance Advantages

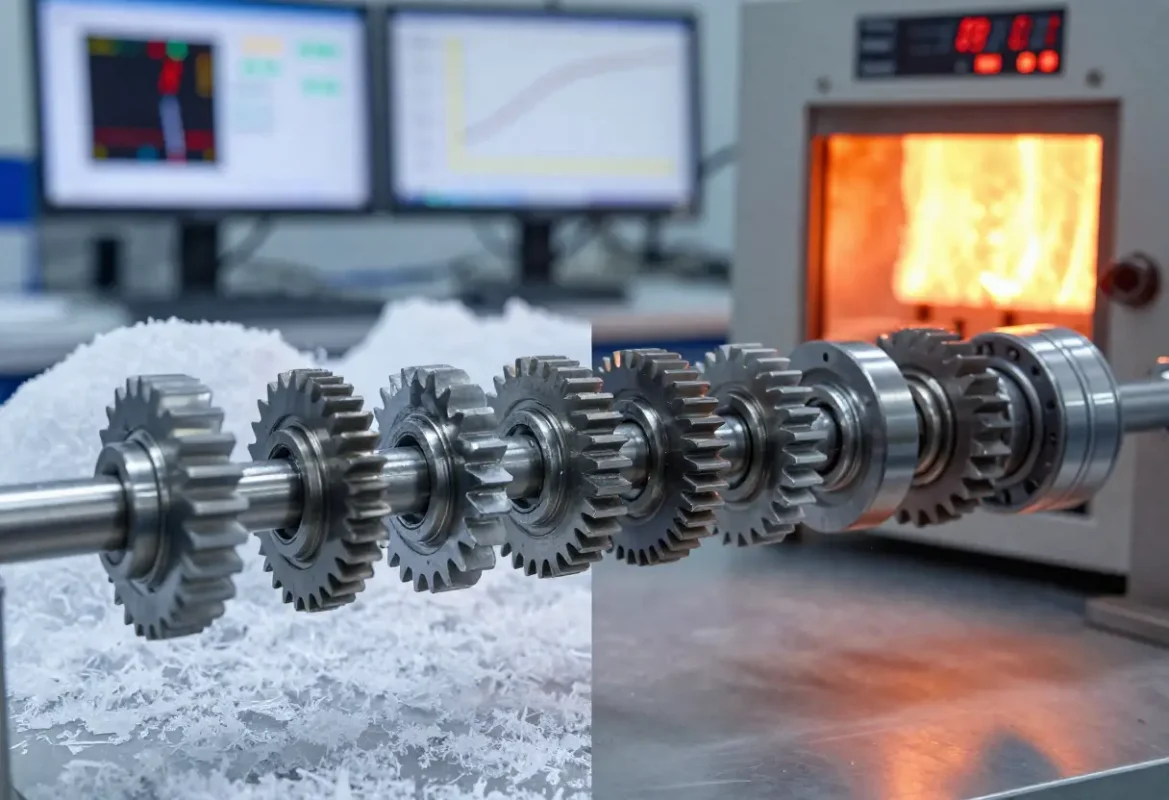

High Temperature Resistance

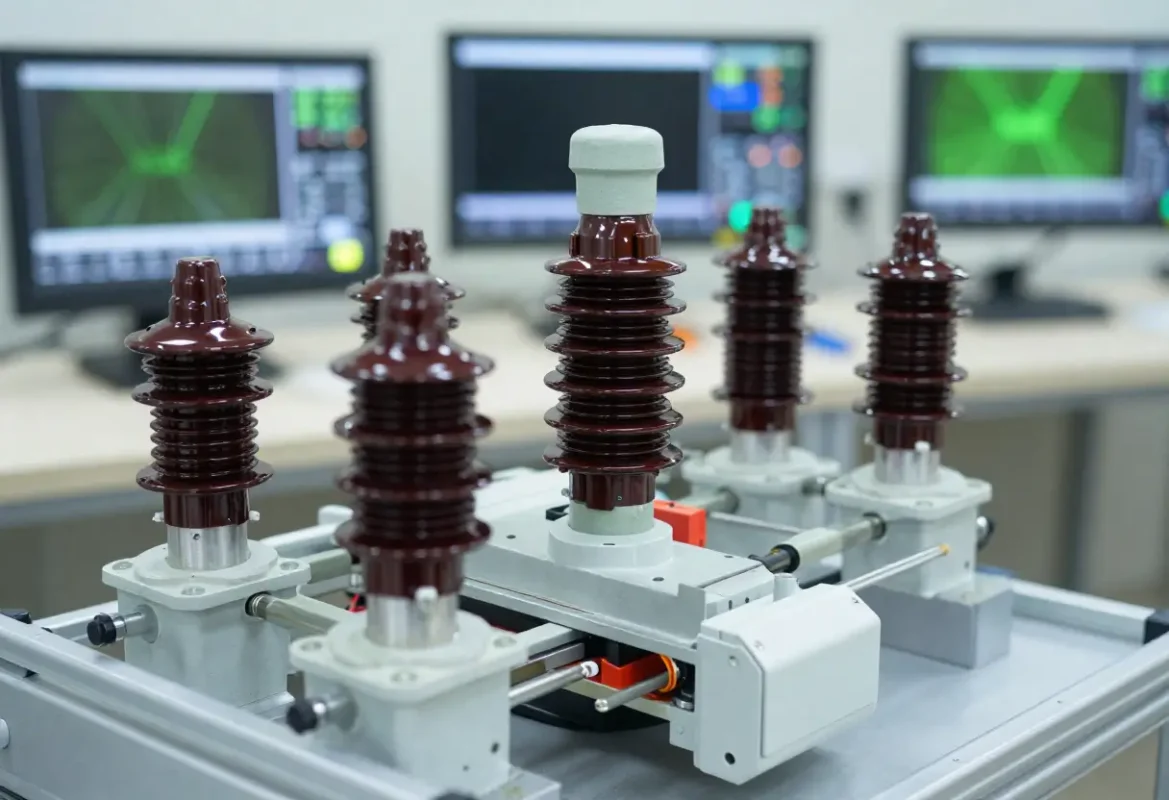

High Electrical Insulation

Among insulation materials, PI application is in the field with the highest insulation requirements. To meet actual user needs, PI must have electrical properties, strength, and extremely high performance that exceed standards. Allstar Material’s modified PI features customizable high voltage resistance and other properties to ensure production safety and product quality with outstanding insulation capability.

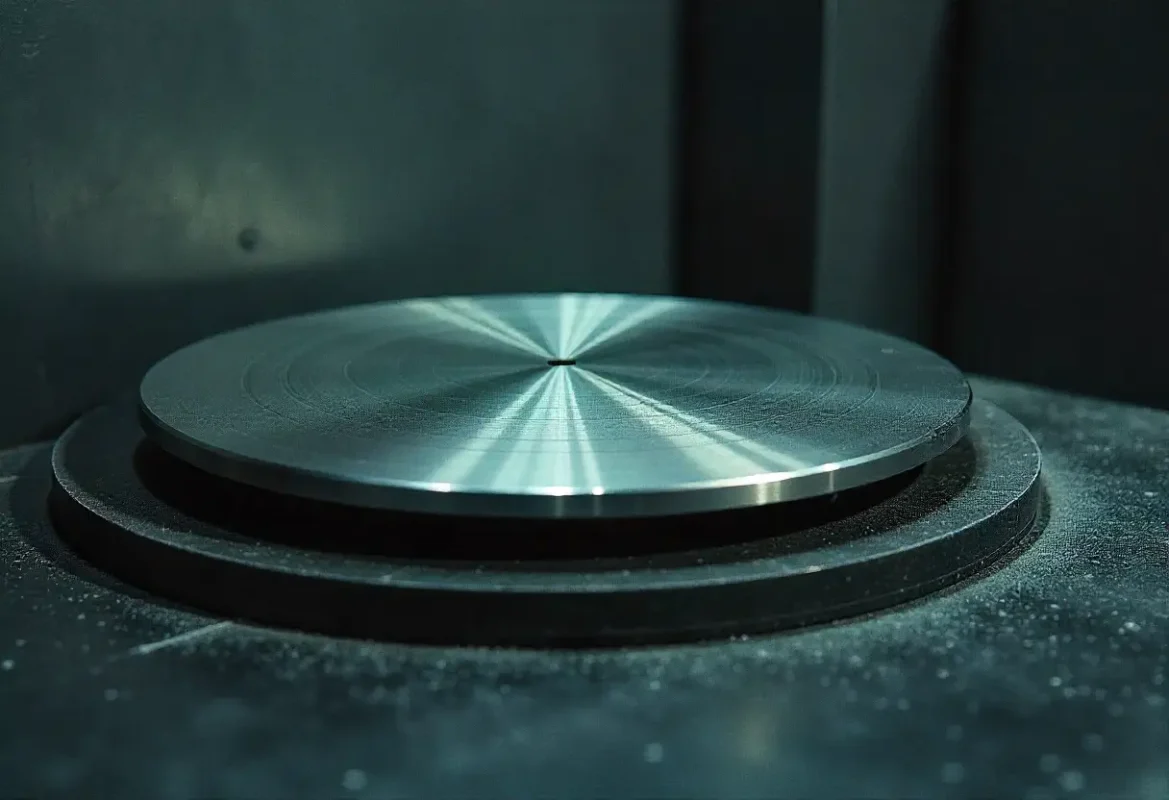

Low Friction Coefficient and Self-Lubricating Properties

For various equipment requiring high lubrication and reduced wear component friction coefficients, component overheating, component failure, and overall performance improvement, Allstar Material has developed modified PI through independent research, which is oil-free and self-lubricating, suitable for a wide range of applications, providing excellent hardness and low temperature performance.

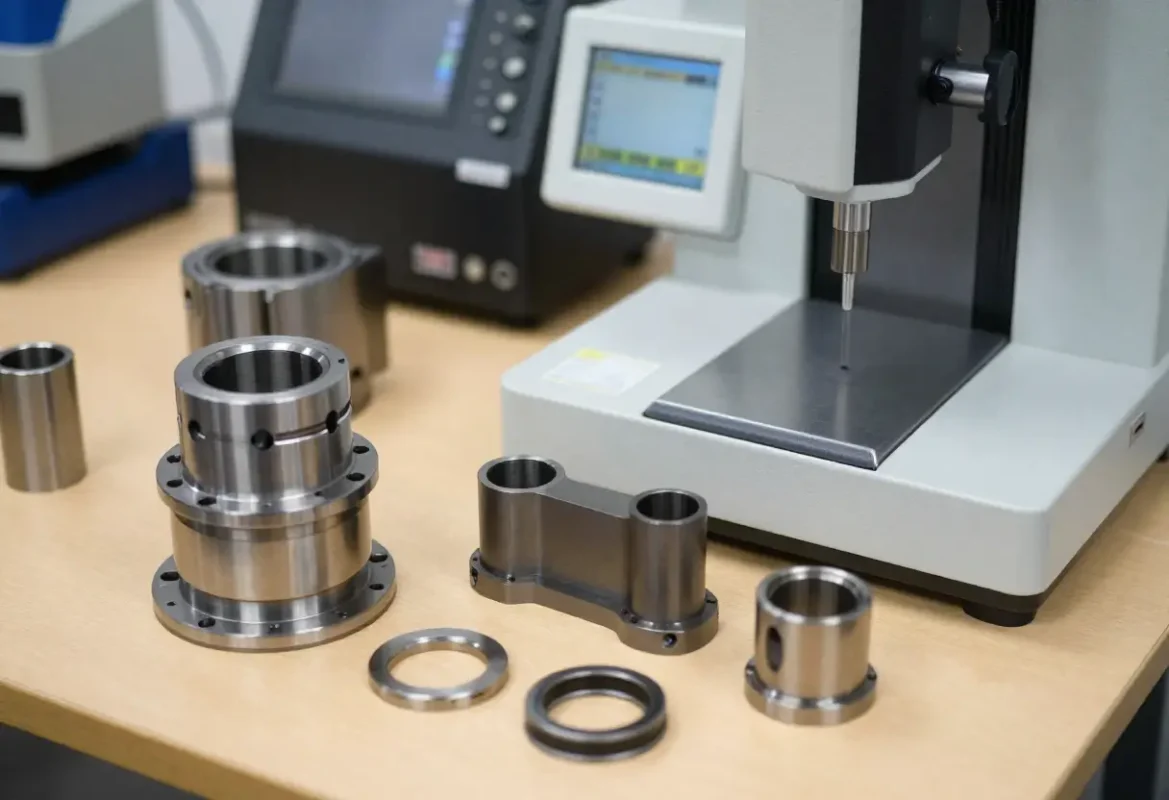

Mechanical Strength and Dimensional Stability

Allstar Material Can Provide the Following Modified PI - (Continued)

A-PI-350-21 Modified polyimide resin

Used for manufacturing thermal insulation gaskets, valve seat inserts, pistons, seals, etc.

A-PI-211 Modified polyimide resin

Used for manufacturing rotating dynamic sealing gaskets, static high and low temperature resistant gaskets, oil-free bearings, etc.

A-PI-5050 Modified polyimide resin

Used for manufacturing thermal spray coating support devices, cores, actuators, pushers, extractors, startup components, etc.

A-PI-MS Modified polyimide resin

Used for manufacturing transmission components, seals, gaskets, etc.

A-PI Functional polyimide resin, A-PI-D and A-PI-F

Used for manufacturing anti-static and conductive密封零器 components.

A-PI-3S Filled polyimide resin

A minimal amount of addition can significantly improve the wear resistance and toughness of PTFE products, and can be used as an adhesive for grinding wheel manufacturing.

Applications of Modified PI

Aerospace Field

Electronics and Semiconductor Industry

Conductive or anti-static modified PI. For example, used for manufacturing chip testing tools, fixing circuit boards and precision electronic equipment insulation cushions, effectively preventing electrostatic discharge (ESD) damage to electronic components, ensuring production line safety.