PEEK CNC Machining

PEEK CNC Machining refers to the process of utilizing computer numerical control (CNC) equipment to perform high-precision cutting on PEEK (polyether ether ketone) rods, plates or tubes to create complex shaped parts.

Contact Us

Why PEEK is the Material of Choice for High-Performance Applications

PEEK offers an exceptional combination of mechanical strength, chemical resistance, and thermal stability, making it ideal for demanding environments. Its lightweight nature, low moisture absorption, and excellent wear properties provide long-lasting performance in aerospace, medical, automotive, and industrial applications.

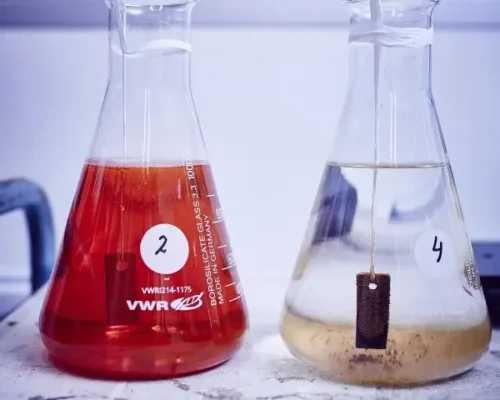

Chemical Resistance

Excellent resistance to a wide range of organic and inorganic chemicals.

Dimensional Stability

Low moisture absorption and low coefficient of thermal expansion ensure dimensional accuracy.

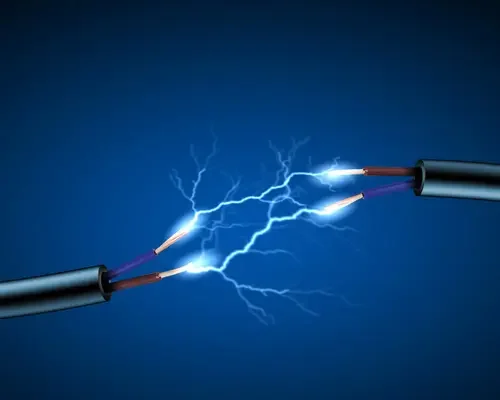

Electrical insulation

(unfilled and fiberglass reinforced grades) excellent insulation properties.

PEEK Material Grade Properties

PEEK is available in various grades—such as unfilled, glass-filled, and carbon-filled—each engineered to meet specific performance needs. These grades differ in terms of strength, stiffness, thermal resistance, and wear properties, allowing for tailored solutions across a wide range of high-performance applications.

|

Unfilled PEEK (Natural PEEK) |

|

|---|---|

|

Toughness/Ductility |

Elongation at break approx. 25-50%. |

|

Electrical Insulation |

Dielectric strength approx. 18-20 kV/mm; bulk resistivity approx. 10^16 Ohm-cm. |

|

FDA Compliance |

FDA compliant for specific grades. |

|

Tensile Strength |

approx. 95 MPa. |

|

Continuous Use Temperature |

260°C. |

|

PEEK CF30 (30% Carbon Fiber Reinforced) |

|

|---|---|

|

Stiffness |

Flexural Modulus approx. 20-25 GPa. |

|

Tensile Strength |

>200 MPa. |

|

Creep Strength |

Significantly better than unfilled PEEK at elevated temperatures. |

|

Thermal Conductivity |

Approx. 0.7-1.0 W/(m·K) (Significantly better than unfilled PEEK). Thermal conductivity: approximately 0.7-1.0 W/(m-K) (significantly higher than unfilled PEEK) |

|

Wear resistance |

Significantly better than unfilled PEEK (lower wear factor in specific wear tests). |

|

Coefficient of thermal expansion (CLTE) |

approx. 15-25 µm/(m-°C) (low thermal expansion). |

|

PEEK GF30 (30% glass fiber reinforced) |

|

|---|---|

|

Strength & Stiffness |

Tensile strength approx. 160+ MPa; flexural modulus approx. 10-12 GPa. |

|

Dimensional Stability |

Coefficient of Thermal Expansion (CLTE) approx. 20-30 µm/(m-°C) (better than unfilled PEEK). |

|

Cost-effectiveness |

Provides enhanced performance at a lower cost than carbon fiber reinforcement. |

|

Electrical insulation |

Dielectric strength approx. 18-20 kV/mm; bulk resistivity approx. 10^15-10^16 Ohm-cm. |

|

PEEK Bearing Grade (10% GF+ 10% CF+10% PTFE) |

|

|---|---|

|

Low friction |

Dynamic coefficient of friction approx. 0.15-0.25. |

|

Wear resistance |

Optimized for low wear rates and suitable for high load sliding applications. |

|

Self-lubricating properties |

Solid lubricant included, no external lubrication required. |

|

PV Limits |

High, typically in excess of 1.5 MPa-m/s (non-lubricated, depending on mating material and operating conditions). |

|

Compressive strength |

high, can withstand heavy loads. |

Dalian Allstar PEEK CNC Machining Advantage

Dalian Allstar stands out with advanced CNC capabilities, over a decade of machining expertise, and a strong focus on high-performance materials like PEEK. Our precision equipment, strict quality control, and ability to deliver custom, complex parts ensure reliable performance and customer satisfaction across industries such as aerospace, medical, and electronics.

Professional experience

With many years of experience in precision machining of PEEK materials and more than 20 professional technical team, we have a very good understanding of the properties of different types of peek.

Advanced equipment

Equipped with high precision multi-axis CNC machining centers.

Material Expertise

We have a good understanding of the properties and processing difficulties of different PEEK grades.

Quality Control

Selective dimensional and surface inspections during the machining process to ensure that each product is inspected before leaving the factory.

Customization Capability

We have a technical team of more than 20 people who specialize in processing for customer drawings or samples.

Inventory Support

We stock a wide range of PEEK raw materials, including plates, rods, tubes, etc., to minimize the material procurement cycle and speed up the delivery time.

PEEK Machining Considerations

PEEK is available in several machinable forms, including unfilled PEEK, glass fiber-reinforced PEEK, carbon fiber-reinforced PEEK, and bearing-grade PEEK. Each type offers unique properties—such as enhanced strength, stiffness, wear resistance, or self-lubrication—making them ideal for specific industrial and engineering applications.

Thermal Management

PEEK has poor thermal conductivity and is prone to heat buildup. Sharp tools (carbide or PCD are recommended) and effective cooling (e.g. compressed air or suitable coolant) are essential.

Cutting parameters

Cutting speeds (typically in the range of 150-300 m/min, depending on the tool and operation) and feed rates (e.g. 0.1-0.3 mm/rev) need to be optimized to avoid overheating and melting of the material.

Stress control

PEEK materials may have internal stresses. Complex or high-precision parts require annealing (e.g., 150-200°C holding time for a few hours followed by slow cooling) before machining, and for modified materials, deep-cooling can be used to relieve stresses. Excessive clamping forces should be avoided during machining.

Tool wear

Reinforced PEEK (CF30, GF30) has a high impact on tool wear. Wear-resistant and sharp tools should be used and replaced in a timely manner.

Machinable PEEK Types

Dalian Allstar can precisely machine the following major PEEK grades

Unfilled PEEK (Natural PEEK

PEEK CF30 (Carbon Fiber Reinforced)

PEEK GF30 (Glass Fiber Reinforced)

PEEK Bearing Grades (Various types of Wear Resistant Grades)

Contact Us

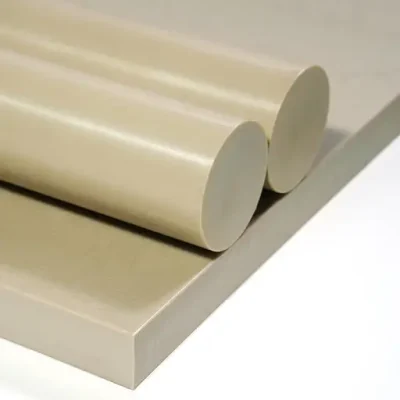

Machinable Raw Material Shapes

We are capable of CNC machining PEEK based on the following PEEK raw material shapes. CNC machining:

PEEK Plates / Sheets

PEEK Rods

PEEK Tubes

Dalian Allstar is the preferred partner for high performance PEEK CNC precision machining. We have multi-axis equipment, excellent knowledge of the material properties of unfilled to reinforced/bearing grade PEEK, and manufacture under a quality management system that guarantees high precision customized parts for our customers. Responding quickly to global needs, we specialize in high precision and high performance parts, providing one-stop PEEK solutions.