Advantages of PEEK Compression Molding

High Strength & High Temperature Resistance (>260°C Continuous Use)

PEEK material maintains stable strength and rigidity even in high-temperature environments. Parts molded using the compression molding process can withstand continuous operating temperatures up to 260°C, and short-term exposure can exceed 300°C. This makes PEEK ideal for aerospace, automotive engine compartments, and other high-temperature industrial applications. Compared to other thermoplastics, PEEK’s performance shows minimal degradation at high temperatures, ensuring long-term, reliable operation.

Excellent Chemical Resistance (Strong Acids, Bases, Solvent Environments)

PEEK exhibits outstanding corrosion resistance against strong acids, strong bases, organic solvents, and various industrial chemicals. Unlike metals, PEEK does not rust or react chemically, making it an ideal solution for applications exposed to corrosive media, such as in chemical equipment, pump valves, and seals. Compression molded PEEK parts provide a more durable and cost-effective alternative to metals in these environments.

Good Dimensional Stability

PEEK compression molded products retain stable dimensions and shapes under thermal cycles, humidity changes, and mechanical loads. This stability is crucial for high-precision parts, such as electrical connectors, precision pump valve components, and aerospace fasteners. PEEK’s low water absorption rate (<0.5%) ensures stable performance even in damp or submerged environments.

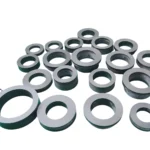

Ideal for Large, Thick-Walled Parts

Compared to injection molding, compression molding is more suitable for producing large, thick-walled, and geometrically simple parts. The compression process ensures even distribution of pressure and temperature, resulting in lower internal stresses and a reduced risk of warping or cracking. Therefore, compression molding is the ideal method for manufacturing large-diameter valve seats, load-bearing supports, and thick-walled insulating components.

Disadvantages of PEEK Compression Molding

High Mold Costs

This process involves molding within a mold, and the requirements for the mold are quite high, leading to higher initial investment costs.

Limited Geometric Complexity

Compression molding is suitable for producing simple parts. For more complex geometries, we recommend using injection molding or 3D printing processes instead.

Larger Dimensional Tolerance Range

After compression molding, additional precision machining processes, such as CNC turning or CNC machining, are typically required to achieve the desired tight dimensional tolerances.