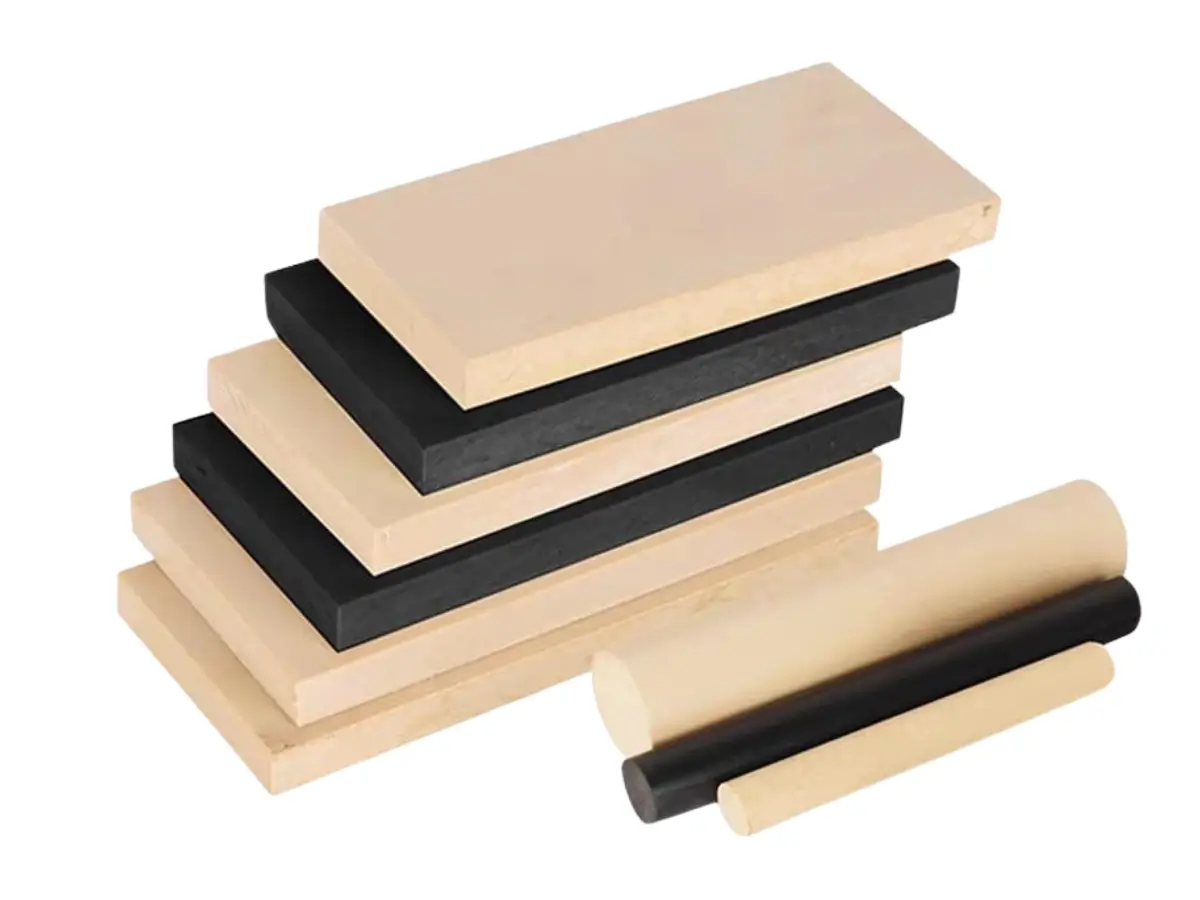

PEEK Grades Available from Allstar Material

Main Grades and Properties of PEEK Plates

Pure PEEK Plates:

Properties: Highest toughness, best impact resistance, highest purity.

Applications: Medical implants, food processing equipment components.

30% Carbon Fiber Reinforced PEEK Plates (CF30 PEEK):

Properties: Highest strength and rigidity in the PEEK family, conductive, excellent wear resistance.

Applications: Aerospace structural components, semiconductor wafer carriers, high-load gears.

30% Glass Fiber Reinforced PEEK Plates (GF30 PEEK):

Properties: High strength, high rigidity, extremely high heat deflection temperature, excellent dimensional stability.

Applications: Industrial structural components, pump and valve parts, electrical insulation components.

Bearing Grade PEEK Plates:

Properties: Added PTFE, graphite, and carbon fiber for extremely low friction coefficient, excellent wear resistance.

Applications: Bushings, bearings, seals.

Performance Table for Different Grades of PEEK Plates

Mechanical Behavior

| Item | Material Grade | |||||

|---|---|---|---|---|---|---|

| Pure PEEK | GF30 PEEK | CF30 PEEK | Bearing grade PEEK | |||

| Test Standard or Instrument | Unit | 100%PEEK | PEEK+30%Glass Fiber | PEEK+30%Carbon Fiber | PEEK+10%Carbon Fiber+10%Graphite+10%PTFE | |

| Tensile strength(23°C) | ISO527 | MPa | 100 | 155 | 220 | 134 |

| Bending strength(23°C) | ISO 178 | MPa | 163 | 212 | 298 | 186 |

| Compressive strength(23°C) | ISO 604 | MPa | 118 | 215 | 240 | 150 |

| Lzod impact strength( no gap) | ISO 180/IU | kJ/m² | No Crack | 51 | 46 | 32 |

Thermal Performance

| Item | Material Grade | |||||

|---|---|---|---|---|---|---|

| Pure PEEK | GF30 PEEK | CF30 PEEK | Bearing grade PEEK | |||

| Test Standard or Instrument | Unit | 100%PEEK | PEEK+30%Glass Fiber | PEEK+30%Carbon Fiber | PEEK+10%Carbon Fiber+10%Graphite+10%PTFE | |

| Melting point | DSC 11357 | °C | 343 | 343 | 343 | 343 |

| Distortion temperature | ISO 75-1/2 | °C | 163 | 315 | 315 | 293 |

| Continuous using temperature | UL 74685 | °C | 260 | 260 | 260 | 260 |

| Coefficient of thermal expansion | ASTM D696 | 10 -5°C | 4.7 | 2.2 | 1.5 | 2.2 |

| Flammable level | UL 94 | V-0@mm | 1.5 | 1.5 | 1.5 | 0.75 |

Electrical Performance

| Item | Material Grade | |||||

|---|---|---|---|---|---|---|

| Pure PEEK | GF30 PEEK | CF30 PEEK | Bearing grade PEEK | |||

| Test Standard or Instrument | Unit | 100%PEEK | PEEK+30%Glass Fiber | PEEK+30%Carbon Fiber | PEEK+10%Carbon Fiber+10%Graphite+10%PTFE | |

| Dielectric strength | IEC 60243-1 | kV/mm | 18 | 19 | ||

| Dielectric constant | IEC60250 | – | 3.2 | 3.3 | ||

| Surface resistivity | Ω | 1015 | 1015 | 3*106 | 5*106 | |

Other Performance

| Item | Material Grade | |||||

|---|---|---|---|---|---|---|

| Pure PEEK | GF30 PEEK | CF30 PEEK | Bearing grade PEEK | |||

| 100%PEEK | PEEK+30%Glass Fiber | PEEK+30%Carbon Fiber | PEEK+10%Carbon Fiber+10%Graphite+10%PTFE | |||

| Test Standard or Instrument | Unit | |||||

| Density | ISO 1183 | g/cm³ | 1.3±0.01 | 1.5±0.01 | 1.4±0.01 | 1.43±0.01 |

| Rockwell hardness | ISO 2039 | HRR | 118 | 119 | 121 | 108 |

| Friction coefficient | μ | 0.30-0.38 | 0.38-0.46 | 0.28 | 0.18 | |

| Water Abs. (25°C.24Hrs) | ISO 62 | % | 0.5 | 0.11 | 0.06 | 0.06 |

| Mould shrinking percentage | 3mm,170°C, Flow direction | % | 1.2 | 0.4 | 0.1 | 0.3 |

| Perpendicular to flow direction | % | 1.5 | 0.8 | 0.5 | 0.5 | |

Specifications of PEEK Plates

At Dalian Allstar, we offer PEEK plates with the following specifications:

| Thickness (mm) | Width (mm) | Length (mm) | Approx. Weight per Meter (kg/m)* |

|---|---|---|---|

| 4 | 600 | 3000 | 3.14 |

| 5 | 600 | 3000 | 3.93 |

| 6 | 600 | 3000 | 4.72 |

| 8 | 600 | 3000 | 6.29 |

| 10 | 600 | 3000 | 7.86 |

| 12 | 600 | 3000 | 9.43 |

| 15 | 600 | 3000 | 11.79 |

| 20 | 600 | 3000 | 15.72 |

| 25 | 600 | 3000 | 19.65 |

| 30 | 600 | 3000 | 23.58 |

| 35 | 600 | 3000 | 27.51 |

| 40 | 600 | 3000 | 31.44 |

| 45 | 600 | 3000 | 35.37 |

| 50 | 600 | 3000 | 39.3 |

| 55 | 600 | 3000 | 43.23 |

| 60 | 600 | 3000 | 47.16 |

| 65 | 600 | 3000 | 51.09 |

| 70 | 600 | 3000 | 55.02 |

| 75 | 600 | 3000 | 58.95 |

| 80 | 600 | 3000 | 62.88 |

| 85 | 600 | 3000 | 66.81 |

| 90 | 600 | 3000 | 70.74 |

| 95 | 600 | 3000 | 74.67 |

| 100 | 600 | 3000 | 78.6 |

| 105 | 600 | 3000 | 82.53 |

| 110 | 600 | 3000 | 86.46 |

| 115 | 600 | 3000 | 90.39 |

| 120 | 600 | 3000 | 94.32 |

Note: Weight per meter is calculated based on the density of unfilled PEEK (approx. 1.31 g/cm³) and is provided for reference only. The actual weight of filled-grade PEEK plates will vary due to different densities. Please contact us for precise weight information regarding specific grades.

Thickness Selection Guide Based on Common Applications:

- 4-10mm: Thin structural components, seals, gaskets, electrical insulators

- 12-25mm: Bearing components, valve bodies, moderate-load structural parts

- 30-50mm: Heavy-duty bearings, thick-wall pressure vessels, large gears

- 60-120mm: Massive structural components, large bearing races, thick plates for multiple parts