Differences and Applications of Different Grades of PEEK Rods

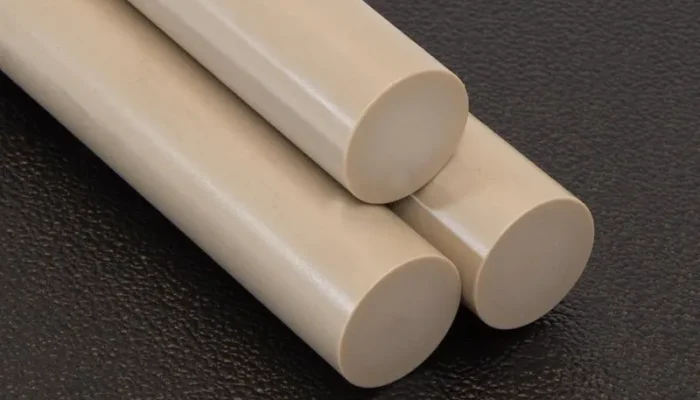

Unfilled PEEK Rods (Pure PEEK)

Properties: This is the most basic grade of PEEK rods, without any additives. It offers the highest toughness and best impact resistance in the PEEK family. It also has extremely high purity, meeting FDA and other certification standards.

Applications: Commonly used in parts requiring high purity and toughness, such as medical implants, food processing machine components, and precision parts that need to absorb impacts.

CF30 PEEK Rods (30% Carbon Fiber Reinforced PEEK)

Properties: Contains 30% carbon fiber, significantly enhancing the material's strength, rigidity, and creep resistance. The addition of carbon fiber also provides conductivity, allowing it to dissipate static electricity.

Applications: Suitable for components requiring high load capacity, high rigidity, and static dissipation, such as aerospace structural components, semiconductor equipment fixtures, and test probes.

GF30 PEEK Rods (30% Glass Fiber Reinforced PEEK)

Properties: Contains 30% glass fiber, providing very high rigidity and heat deflection temperature, allowing it to maintain its shape stability even at high temperatures. However, glass fiber also makes the material more brittle and abrasive.

Applications: Primarily used for structural components that need to withstand high loads and high temperatures, such as industrial gears, pump and valve components, and electrical insulation parts.

Bearing Grade PEEK Rods

Properties: Typically made from a combination of carbon fiber, graphite, and PTFE or other fillers. This combination gives the material an extremely low friction coefficient and excellent wear resistance, providing superior self-lubricating properties.

Applications: Specifically designed for sliding and friction applications, such as manufacturing bushings, bearings, seals, and piston rings.

Performance Table for Different Grades of PEEK Rods

| Item | Test Standard or Instrument | Unit | Pure PEEK | GF30 PEEK | CF30 PEEK | Bearing grade PEEK |

|---|---|---|---|---|---|---|

| 100%PEEK | PEEK+30%Glass Fiber | PEEK+30%Carbon Fiber | PEEK+10%Carbon Fiber+10%Graphite+10%PTFE | |||

| Tensile strength(23°C) | ISO527 | MPa | 100 | 155 | 220 | 134 |

| Bending strength(23°C) | ISO 178 | MPa | 163 | 212 | 298 | 186 |

| Compressive strength(23°C) | ISO 604 | MPa | 118 | 215 | 240 | 150 |

| Lzod impact strength( no gap) | ISO 180/IU | kJ/m² | No Crack | 51 | 46 | 32 |

| Item | Test Standard or Instrument | Unit | Pure PEEK | GF30 PEEK | CF30 PEEK | Bearing grade PEEK |

|---|---|---|---|---|---|---|

| 100%PEEK | PEEK+30%Glass Fiber | PEEK+30%Carbon Fiber | PEEK+10%Carbon Fiber+10%Graphite+10%PTFE | |||

| Melting point | DSC 11357 | °C | 343 | 343 | 343 | 343 |

| Distortion temperature | ISO 75-1/2 | °C | 163 | 315 | 315 | 293 |

| Continuous using temperature | UL 74685 | °C | 260 | 260 | 260 | 260 |

| Coefficient of thermal expansion | ASTM D696 | 10 -5°C | 4.7 | 2.2 | 1.5 | 2.2 |

| Flammable level | UL 94 | V-0@mm | 1.5 | 1.5 | 1.5 | 0.75 |

| Item | Test Standard or Instrument | Unit | Pure PEEK | GF30 PEEK | CF30 PEEK | Bearing grade PEEK |

|---|---|---|---|---|---|---|

| 100%PEEK | PEEK+30%Glass Fiber | PEEK+30%Carbon Fiber | PEEK+10%Carbon Fiber+10%Graphite+10%PTFE | |||

| Dielectric strength | IEC 60243-1 | kV/mm | 18 | 19 | ||

| Dielectric constant | IEC60250 | – | 3.2 | 3.3 | ||

| Surface resistivity | Ω | 1015 | 1015 | 3*106 | 5*106 | |

| Item | Test Standard or Instrument | Unit | Pure PEEK | GF30 PEEK | CF30 PEEK | Bearing grade PEEK |

|---|---|---|---|---|---|---|

| 100%PEEK | PEEK+30%Glass Fiber | PEEK+30%Carbon Fiber | PEEK+10%Carbon Fiber+10%Graphite+10%PTFE | |||

| Density | ISO 1183 | g/cm³ | 1.34±0.01 | 1.5±0.01 | 1.4±0.01 | 1.43±0.01 |

| Rockwell hardness | ISO 2039 | HRR | 118 | 119 | 121 | 108 |

| Friction coefficient | μ | 0.30-0.38 | 0.38-0.46 | 0.28 | 0.18 | |

| Water Abs. (25°C.24Hrs) | ISO 62 | % | 0.5 | 0.11 | 0.06 | 0.06 |

| Mould shrinking percentage | 3mm,170 ℃, Flow direction | % | 1.2 | 0.4 | 0.1 | 0.3 |

| Perpendicular to flow direction | % | 1.5 | 0.8 | 0.5 | 0.5 | |

Allstar Material Available Stock

| 直径 (Diameter) (mm) | 长度 (Length) (mm) | 每米近似重量 (Approx. Weight per Meter) (kg/m)** |

|---|---|---|

| 5 | 3000 | 0.03 |

| 6 | 3000 | 0.04 |

| 8 | 3000 | 0.07 |

| 10 | 3000 | 0.1 |

| 12 | 3000 | 0.15 |

| 15 | 3000 | 0.23 |

| 20 | 3000 | 0.41 |

| 25 | 3000 | 0.64 |

| 30 | 3000 | 0.92 |

| 35 | 3000 | 1.26 |

| 40 | 3000 | 1.65 |

| 45 | 3000 | 2.08 |

| 50 | 3000 | 2.57 |

| 55 | 3000 | 3.11 |

| 60 | 3000 | 3.7 |

| 65 | 3000 | 4.34 |

| 70 | 3000 | 5.03 |

| 75 | 3000 | 5.77 |

| 80 | 3000 | 6.56 |

| 90 | 3000 | 8.3 |

| 100 | 3000 | 10.25 |

| 110 | 3000 | 12.4 |

| 120 | 3000 | 14.76 |

| 130 | 3000 | 17.32 |

| 140 | 3000 | 20.08 |

| 150 | 3000 | 23.05 |

| Note: The weight per meter is based on the density of unfilled PEEK (approximately 1.31 g/cm³) for reference only. The actual weight of different filled grades of PEEK rods may vary due to differences in their densities (e.g., GF30 density is approximately 1.51 g/cm³, CF30 is approximately 1.41 g/cm³, and Bearing Grade is approximately 1.44 g/cm³). Please contact us for precise weight information and current stock availability for specific grades and sizes. | ||

Application areas and typical products of different PEEK rods

Overview of common application areas and typical products made from various PEEK rod grades, based on their specific properties and performance benefits.

Unfilled PEEK rods:

Application Areas

Application areas: General purpose, requiring good toughness, chemical resistance, hydrolysis resistance, electrical insulation and biocompatibility. Suitable for medical, food processing, semiconductor, aerospace and precision instruments.

Typical Products

bearings (low load, low speed), bushings, seals (static), valve seats, rollers, insulators, medical device parts, food contact parts, analyzer parts.

GF30 PEEK rod:

Application

Structural components requiring high rigidity, high strength, excellent dimensional stability and chemical resistance. Commonly used in aerospace, automotive, oil and gas, pumps and valves, and general industry.

Typical Products

structural supports, pump bodies/impellers, valve parts (ball seats, valve flaps), bearing cages, high-load gears, mechanical parts requiring precision tolerances, high-temperature connectors.

CF30 PEEK rods:

Application

For demanding environments requiring very high stiffness, strength, excellent wear resistance, and static dissipative or conductive properties. Commonly used in high performance industrial equipment, motorsports, aerospace, and semiconductor manufacturing equipment.

Typical Products

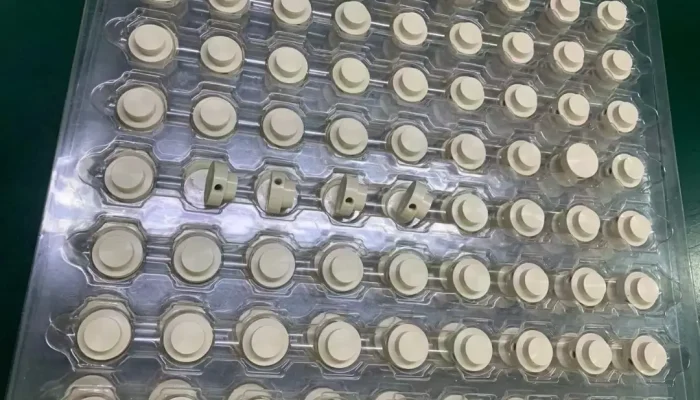

High strength lightweight structural components, wear rings/slides, sealing rings (partial dynamic seals), piston components, compressor parts, wafer handling components (anti-static), test sockets.

Bearing Grade PEEK Rods:

Application Areas:

Core applications are sliding friction components, especially under high loads, high speeds (high PV values), dry running or boundary lubrication conditions. Widely used in automotive, industrial machinery, aerospace, office equipment and other fields.

Typical Products

slide bearings (self-lubricating bearings), bushings, thrust washers, wear strips/slides, sealing rings (especially for rotary and reciprocating motions), piston rings, gears (requiring low friction and long service life), guide rails.