Polyimide PI Film Product Showcase

Polyimide film features high temperature resistance, high strength, excellent insulation, and high sound reproduction. Through years of research and application, we have developed the following film products.

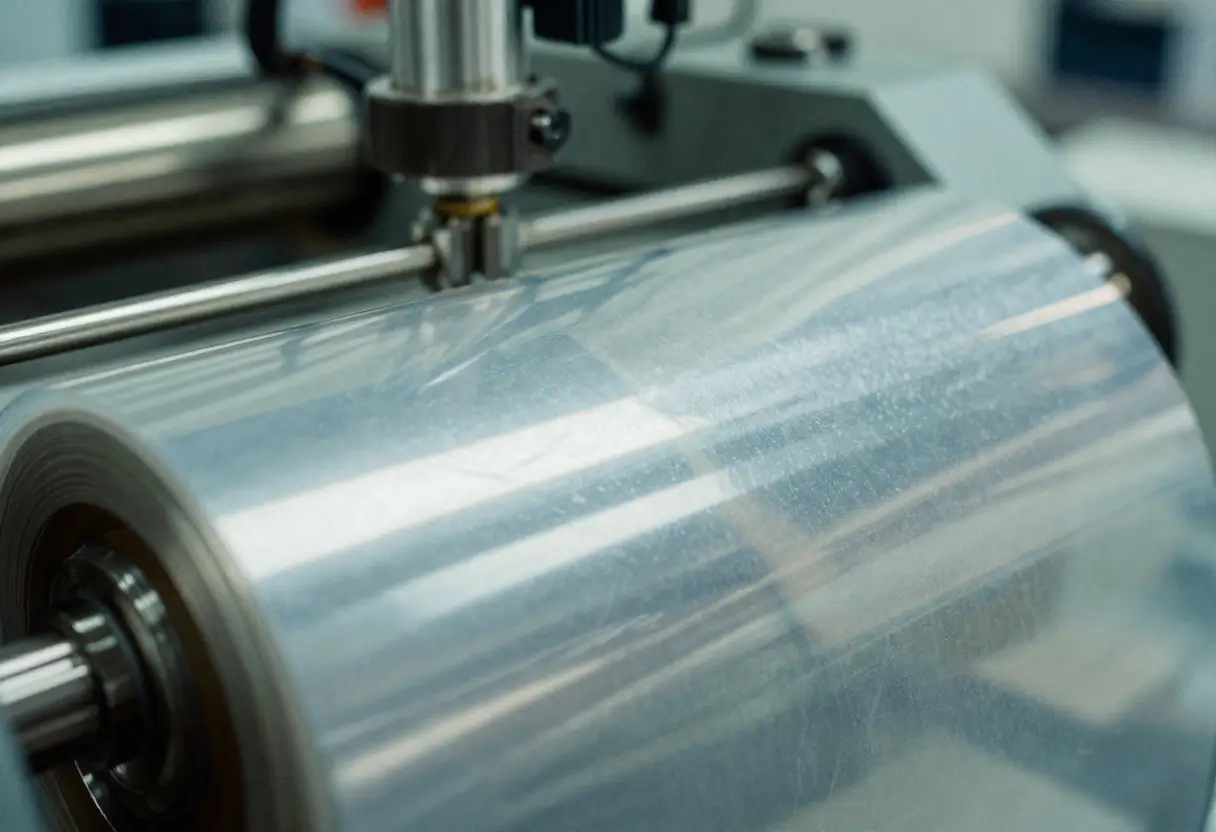

Polyimide Film Sheet

Pure polyimide film without any fillers, maintains its shape for half an hour in a 260℃ environment.

Mainly used in cable insulation, electrical insulation, radiation resistance, solvent resistance, SMT process adhesion, PCB protection, et

Polyimide Film For Voice Coil

It is a synthetic resin composed of pyromellitic dianhydride and 4,4-diaminodiphenyl ether.

In voice coil applications, the voice coil position temperature exceeds 300 degrees Celsius. This specialized film can withstand temperatures of 300℃ perfectly.

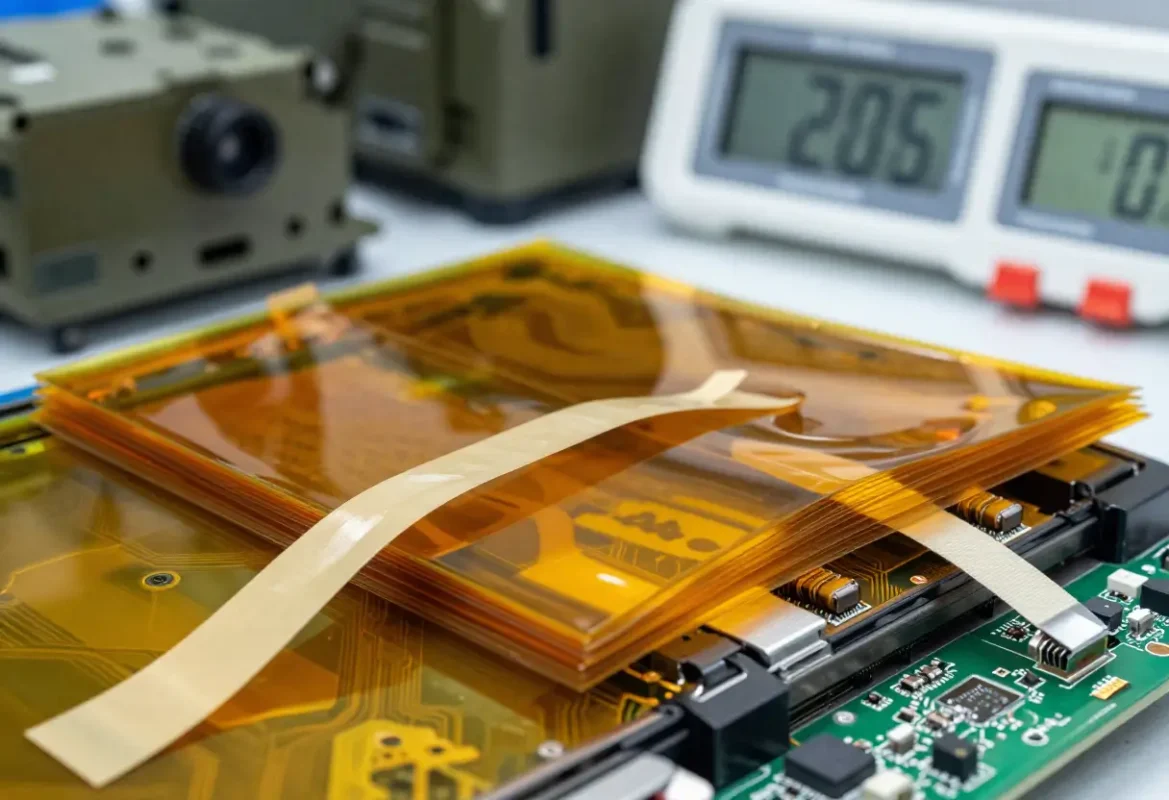

Insulating Polyimide Film

It is a Class H insulation material.

This product features excellent physical, chemical, and electrical properties, with resistance to atomic radiation, solvents, low and high temperatures. It can operate normally in temperature ranges from as low as -452°F (-269℃) to as high as +500°F (+260℃).

This product can be used for flexible printed circuits, flat cables, magnet wire, and motor insulation materials.

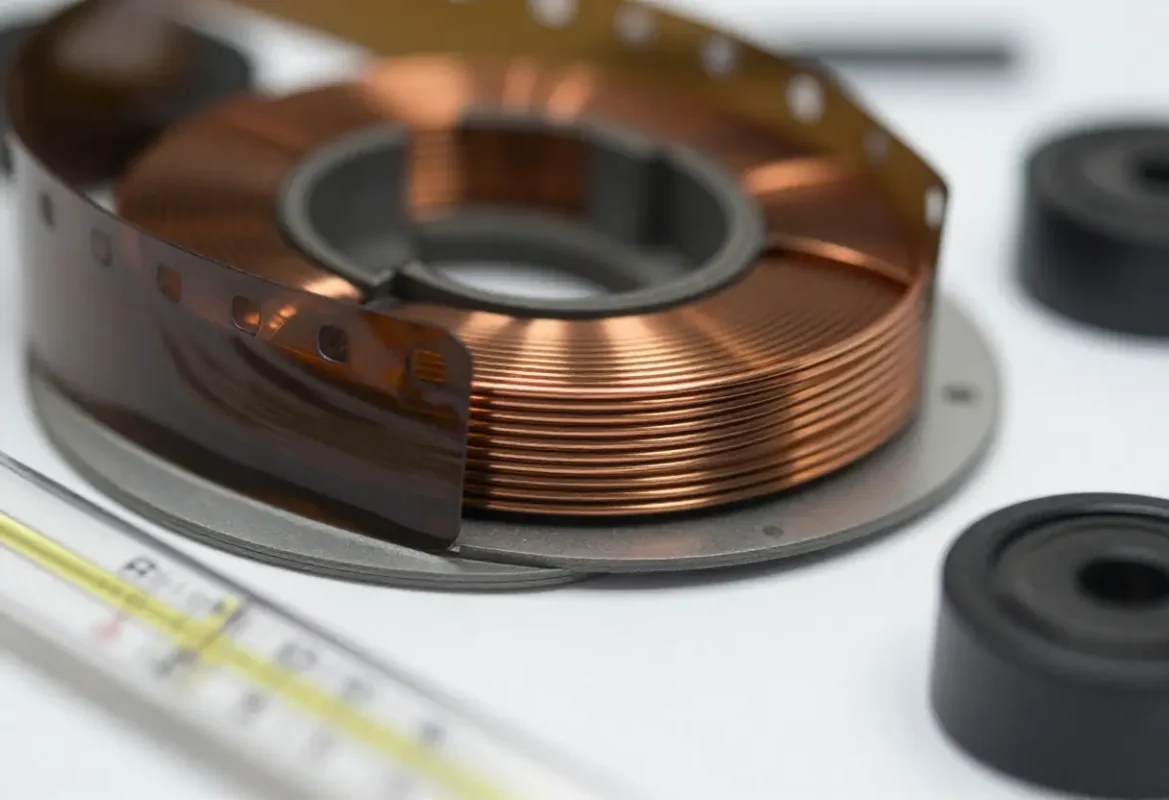

High Temperature Polyimide Film

High Temperature Polyimide Film has a continuous operating temperature range of -195℃ to 400℃, and is widely used in military equipment, satellite navigation, digital products, motors, computers, mobile phones, and other precision products, such as substrate dielectrics in flexible printed circuits (FPC), tape automated bonding (TAB), pressure-sensitive tape (PST), motor insulation, etc.

Key Properties Reference for Unfilled PI Film

The table below lists some key performance indicators of typical pure polyimide film for selection reference (specific values vary by grade, thickness, and test method)

| Property | Unit | Reference Value (Range) | Test Standard (Example) |

|---|---|---|---|

| Density | g/cm³ | 1.40 – 1.43 | ASTM D1505 |

| Tensile Strength (MD) | MPa | 120 – 250 | ASTM D882 |

| Elongation at Break (MD) | % | 30 – 70 | ASTM D882 |

| Elastic Modulus (MD) | GPa | 2.8 – 4.5 | ASTM D882 |

| Continuous Service Temp. | °C | ≥ 260 | UL 746B |

| Glass Transition Temperature (Tg) | °C | 280 – 380+ | DMA |

| Coefficient of Linear Thermal Expansion (CLTE, MD) | ppm/K (10⁻⁶/K) | 15 – 35 | ASTM D696 |

| Volume Resistivity | Ω·cm | > 10¹⁶ | ASTM D257 |

| Dielectric Strength (25μm) | kV/mm | > 150 | ASTM D149 |

| Dielectric Constant (1kHz) | – | 3.2 – 3.5 | ASTM D150 |

| Dissipation Factor (1kHz) | – | 0.002 – 0.005 | ASTM D150 |

| Water Absorption (23°C, 24h) | % | < 1.5 | ASTM D570 |

| Limiting Oxygen Index (LOI) | % | > 35 | ASTM D2863 |

| UL94 Flammability Rating | – | V-0, VTM-0 | UL 94 |

| Note: The data in this table represents typical ranges for general-purpose unfilled PI films and is for reference only. Allstar Material can provide detailed product specifications. Please contact us for precise data on specific grades. | |||

PI Film Specifications Available from Allstar Material (Dalian Allstar)

Dalian Allstar Material Co., Ltd. is committed to providing high-quality PI films in various specifications to global customers. Our available PI film specifications are as follows (theoretical weight per meter calculated based on typical density of 1.42 g/cm³):

| THICKNESS (mm) | WIDTH (mm) | THEORETICAL WEIGHT PER METER (g/m) |

|---|---|---|

| 0.03 | 600 | 25.56 |

| 0.04 | 600 | 34.08 |

| 0.05 | 600 | 42.6 |

| 0.075 | 600 | 63.9 |

| 0.08 | 600 | 68.16 |

| 0.1 | 600 | 85.2 |

| 0.125 | 600 | 106.5 |

| 0.15 | 600 | 127.8 |

| 0.2 | 600 | 170.4 |

| 0.25 | 600 | 213 |

| 0.3 | 600 | 255.6 |

| 0.4 | 600 | 340.8 |

| 0.5 | 600 | 426 |

| 0.75 | 600 | 639 |

| 1 | 600 | 852 |

| 1.2 | 600 | 1022.4 |

| 1.5 | 600 | 1278 |

| 2 | 600 | 1704 |

| 2.5 | 600 | 2130 |

| 3 | 600 | 2556 |

| Calculation Formula Weight per meter (g) = Thickness (mm) × Width (mm) × 1 (meter, i.e., 1000mm) × Density (g/cm³) / 1000 | ||

| Density Note The above weight per meter is calculated based on the typical density of polyimide film of 1.42 g/cm³. The density of different grades or specially treated PI films may vary slightly. | ||

| Customization Service In addition to the above standard specifications, Allstar Material can also provide customized PI film services with other thicknesses, widths, and specific performance requirements according to customer needs. Inquiries are welcome. | ||

Seeking PI Film Solutions with Both Exceptional Performance and Reliability?

Dalian Allstar Material Co., Ltd. is your trusted partner. We offer a comprehensive portfolio of PI film products and can meet your customization needs.