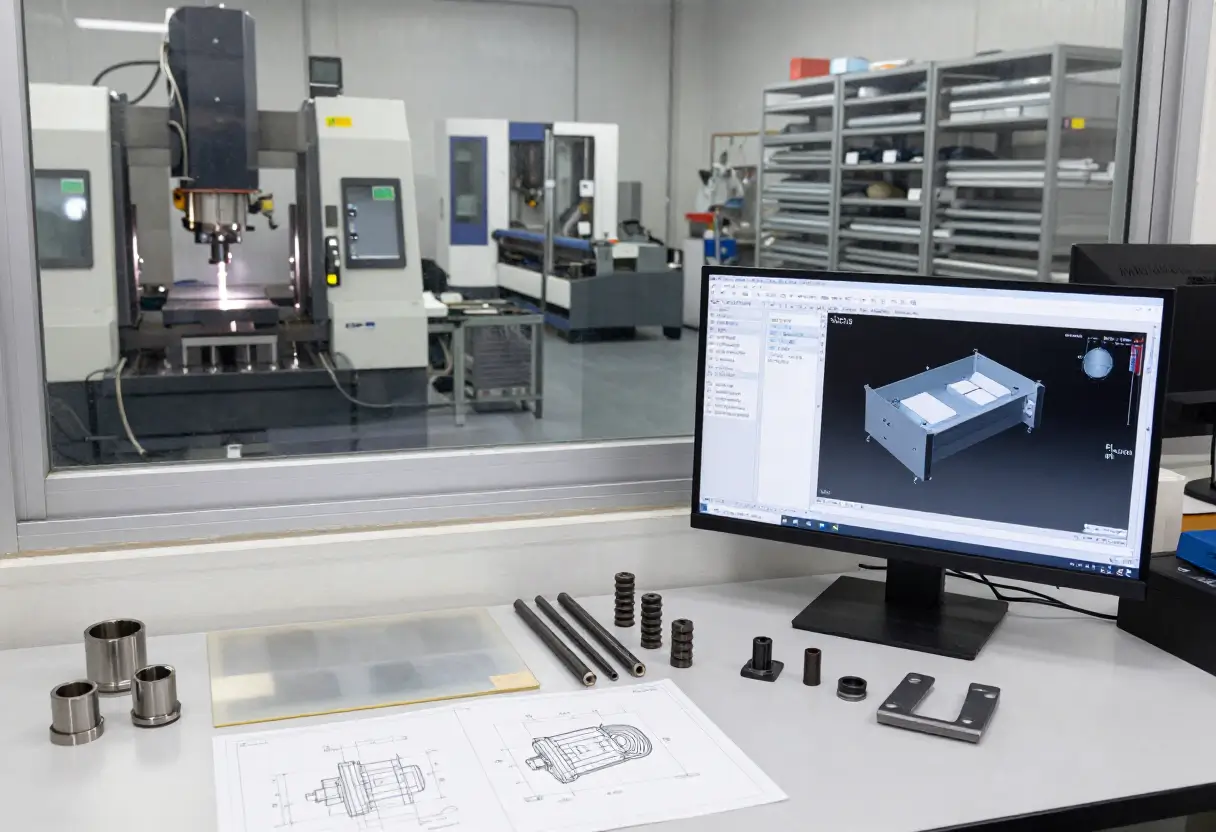

Supports machining from drawings or samples, offering material and design suggestions for customer applications.

Why Choose Polyimide PI

Why Choose Polyimide (PI) Material for Precision Machining?

PI material, due to its unique physical and chemical properties, is an ideal choice for precision machining, especially for:

Extreme Temperature Environments

Components must maintain stable performance from cryogenic (-269°C) to ultra-high temperatures (above +260°C).

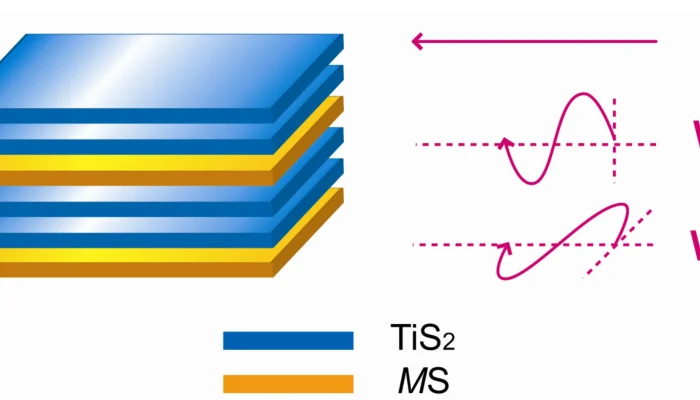

High Precision & Dimensional Stability

Extremely high tolerance requirements for parts, with minimal dimensional change during use.

Wear Resistance & Self-Lubrication:

Used for moving parts requiring low friction, long life, even in oil-free lubrication conditions.

Electrical Insulation

As critical insulation components in high-voltage, high-frequency environments.

Chemical Inertness

Components need to withstand contact with various chemicals, solvents, or fuels.

Low Outgassing

Suitable for vacuum or ultra-high vacuum environments.

Lightweight Requirements

Seeking lighter alternatives to metal while ensuring strength.

Machinability & Challenges

Precision Machinability & Challenges of Polyimide (PI) Material

PI material exhibits good machinability but also presents characteristics requiring professional handling:

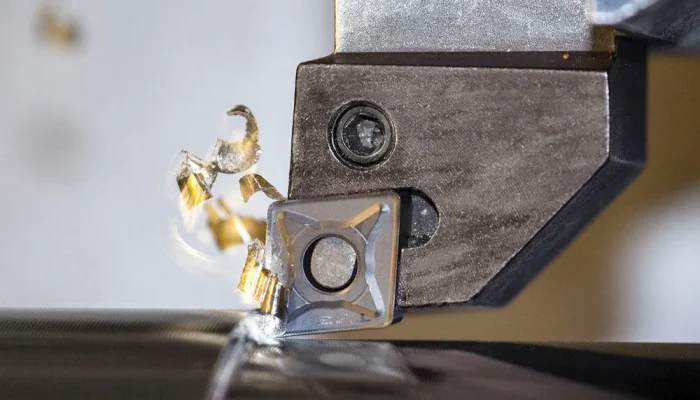

Good Machinability

Can be processed through various traditional and CNC methods such as turning, milling, drilling, tapping, and grinding.

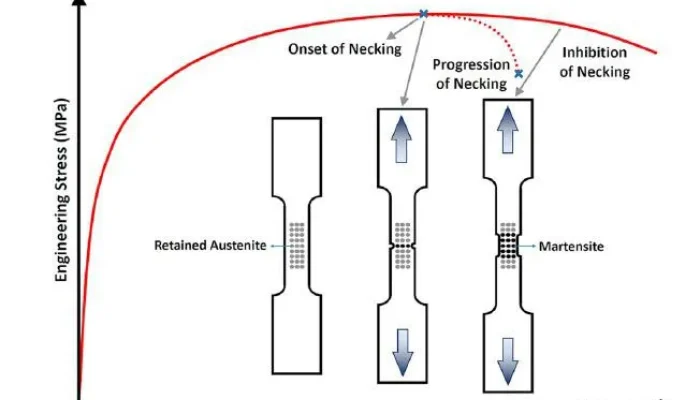

Material Hardness & Toughness

Different PI grades vary in hardness and toughness, necessitating appropriate tool material and cutting parameter selection.

Low Thermal Conductivity

Prone to localized overheating during processing; effective control of cutting heat is crucial to prevent material property degradation.

High Dimensional Stability

While an advantage, this means minute deformations caused by heat or stress during machining must be precisely controlled.

Tool Wear

Some filled or reinforced PI (e.g., glass fiber, carbon fiber reinforced) causes significant tool wear, requiring abrasion-resistant tooling.

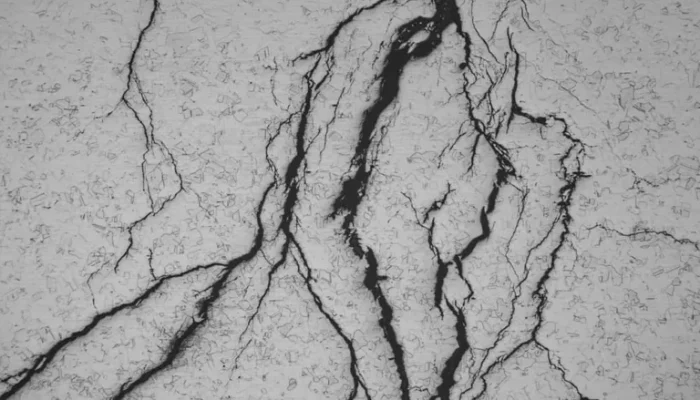

Avoiding Stress Cracking

Unsuitable machining parameters or part structures can lead to internal stress concentration, requiring process optimization and subsequent treatments (e.g., annealing) for elimination.

Dalian Allstar’s Professional Response: Leveraging years of research into PI material characteristics and machining practice at our factory, we have established a mature set of process specifications to effectively address these challenges, ensuring machining accuracy and component quality to meet customer’s practical application needs.

Capabilities & Advantages

Dalian Allstar Material's Polyimide (PI) Precision Machining Capabilities & Advantages

Choosing Dalian Allstar Material as your PI precision machining partner provides:

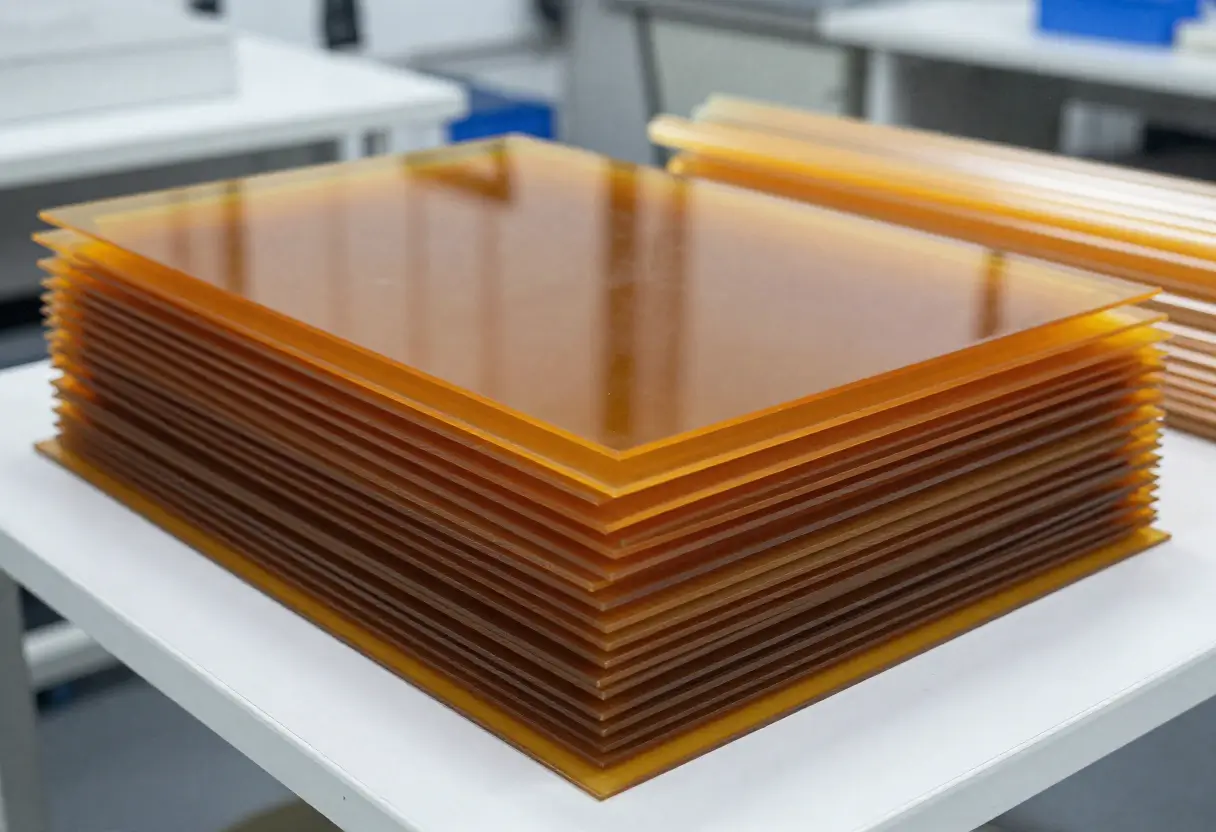

One-Stop Service, from Material to Finished Part

We offer over 1,000 types of PI sheets, rods, and other engineering plastics, available for wholesale, ensuring raw material quality and traceability.

In-house precision machining within our factory shortens the supply chain, improves efficiency, and reduces costs.

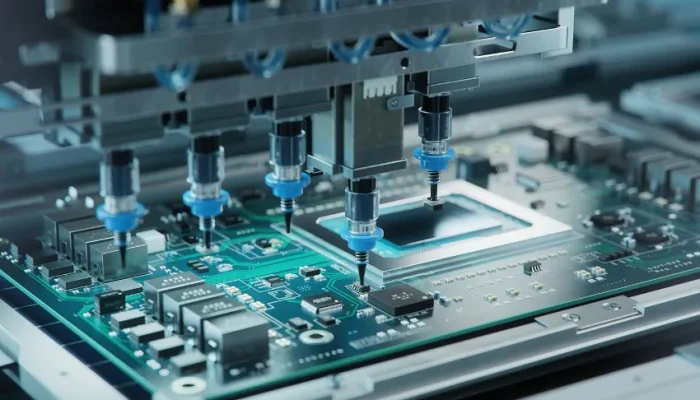

Advanced Machining & Inspection Equipment

Equipped with CNC machining centers, lathes, milling, drilling, grinding, and other advanced equipment.

Equipped with CMMs, profilometers, roughness testers, and over 150 precision instruments, our factory ensures products meet strict tolerance standards.

Experienced Technical Team

Our team of engineers and technicians deeply understands PI material characteristics, enabling them to formulate optimal machining plans for different grades and complex structures.

Possessing years of B2B export experience, we are familiar with international standards and customer needs.

Strict Quality Control System

The entire process, from raw material incoming inspection, in-process control, to final product inspection, adheres to the ISO quality management system.

Detailed material certifications and inspection reports can be provided.

Rapid Response & Customization Services

Capable of quickly responding to customer inquiries and order requirements.

Targeted Industry Solutions

We have extensive experience in manufacturing PI components including nuclear power, military fiber optics, sliding bearings, bushings, EV insulation, cable ties, coil bobbins, bearing cages, bolts, nuts, and audio diaphragms, with a deep understanding of industry requirements.

Types

Types of PI Components We Can Manufacture

Dalian Allstar Material can precision manufacture various PI components according to your drawings and specifications, including but not limited to:

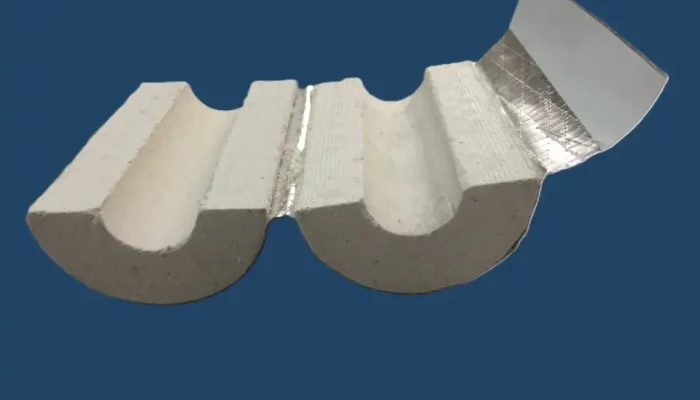

Bearings & Bushings

Self-lubricating PI bearings, high-temperature resistant PI bushings, sliding bearing components.

Seals

PI seal rings, valve seats, gaskets, suitable for high-temperature, high-pressure, or chemically corrosive environments.

Insulation Components

Electrical insulators, coil bobbins, connectors, sockets, precision-formed alternatives to electric vehicle insulation paper.

Structural & Support Parts

High-strength, lightweight PI brackets, frames, fasteners (bolts, nuts).

Precision Rails & Sliders

Low-friction moving parts for precision instruments and equipment.

Medical Device Components

Precision components from biocompatible PI (specific grades required).

Semiconductor & Electronics

Wafer chucks, test sockets, thermal insulation pads.

Aerospace Components

Lightweight, high-temperature resistant structural and functional parts.

Process

Our PI Machining Process Overview

Our precision machining process combines advanced technology, expert craftsmanship, and strict quality control to deliver high-accuracy components. From material selection to final inspection, every step is optimized for efficiency, consistency, and superior performance.

01

Requirement & Drawing Analysis

Deep understanding of customer needs, performance, and tolerance standards.

02

Material Selection & Confirmation

Recommending the most suitable PI grade based on requirements.

03

Process Planning

Designing optimal machining paths, tool selection, and cutting parameters.

04

programming & Machining

Utilizing precision CNC equipment for automated processing.

05

In-Process Inspection

Key dimensions and features are spot-checked or fully inspected during the machining process.

06

Deburring & Surface Treatment

Ensuring smooth component edges and meeting exterior appearance requirements.

07

Final Inspection

Comprehensive quality checks on finished products using precision inspection instruments.

08

Cleaning & Packaging

Professional cleaning and customized packaging to ensure safe product delivery.

Dalian Allstar Material Co., Ltd.

High-quality PI raw materials and superb machining capabilities

is your ideal partner for realizing complex PI component manufacture.