Exceptional Properties of PI Rods

Allstar Material's PI rods inherit the unique inherent performance advantages of polyimide material:

Outstanding High-Temperature Capability

Able to maintain structural and performance stability within a broad temperature range of -269°C to +260°C (some grades can reach higher temperatures for short durations).

Excellent Mechanical Performance

Possesses high tensile strength, high rigidity, and excellent creep resistance, even at elevated temperatures.

Superior Dimensional Stability

Extremely low coefficient of thermal expansion and water absorption rate ensure precise dimensions in environments with temperature and humidity fluctuations.

Good Chemical Inertness

Exhibits good resistance to most organic solvents, oils, and weak acids.

Prominent Electrical Insulation

High dielectric strength and stable dielectric properties make it suitable for demanding electrical insulation components.

Inherent Flame Retardancy

Typically achieves high flame retardancy ratings (e.g., UL94 V-0) without needing added flame retardants.

Excellent Radiation Resistance

Maintains physical integrity and performance in high-energy radiation environments.

Good Self-Lubrication and Wear Resistance

Especially after specific modifications, demonstrates excellent wear resistance and a low coefficient of friction.

Classification of PI Rods

To suit different application scenarios and performance focuses, Allstar Material's PI rods are primarily divided into the following two categories:

Pure PI Rods (Unfilled/Pure PI Rods)

Made from pure polyimide resin, fully demonstrating the fundamental superiority of PI material.

Mainly used in applications with strict requirements for material purity and electrical insulation performance.

Modified/Reinforced PI Rods

Performance is optimized by adding specific fillers (such as graphite, PTFE, glass fiber, carbon fiber, etc.) into the polyimide matrix to enhance specific material attributes.

Increases mechanical strength and stiffness (e.g., glass fiber/carbon fiber reinforced).

Improves wear resistance and reduces friction coefficient (e.g., graphite/PTFE filled, suitable for sliding bearings, bushings).

Enhances thermal conductivity or imparts conductive/antistatic properties (e.g., specific carbon material filling).

Dalian Allstar Material customized modified PI rods

based on specific customer requirements for operating conditions and performance. Available for wholesale purchase from our factory.

| DIAMETER (mm) | LENGTH (mm) | DENSITY (g/cm³) | WEIGHT PER METER (kg) | DIAMETER (mm) | LENGTH (mm) | DENSITY (g/cm³) | WEIGHT PER METER (kg) |

|---|---|---|---|---|---|---|---|

| 5 | 1000 | 1.4 | 0.027 | 40 | 1000 | 1.4 | 1.759 |

| 6 | 1000 | 1.4 | 0.039 | 45 | 1000 | 1.4 | 2.226 |

| 8 | 1000 | 1.4 | 0.07 | 50 | 1000 | 1.4 | 2.749 |

| 10 | 1000 | 1.4 | 0.11 | 55 | 1000 | 1.4 | 3.326 |

| 12 | 1000 | 1.4 | 0.158 | 60 | 1000 | 1.4 | 3.958 |

| 15 | 1000 | 1.4 | 0.247 | 65 | 1000 | 1.4 | 4.646 |

| 16 | 1000 | 1.4 | 0.281 | 70 | 1000 | 1.4 | 5.388 |

| 18 | 1000 | 1.4 | 0.356 | 75 | 1000 | 1.4 | 6.185 |

| 20 | 1000 | 1.4 | 0.44 | 80 | 1000 | 1.4 | 7.037 |

| 22 | 1000 | 1.4 | 0.532 | 85 | 1000 | 1.4 | 7.945 |

| 25 | 1000 | 1.4 | 0.687 | 90 | 1000 | 1.4 | 8.908 |

| 28 | 1000 | 1.4 | 0.862 | 95 | 1000 | 1.4 | 9.926 |

| 30 | 1000 | 1.4 | 0.99 | 100 | 1000 | 1.4 | 10.996 |

| 32 | 1000 | 1.4 | 1.126 | 105 | 1000 | 1.4 | 12.12 |

| 35 | 1000 | 1.4 | 1.347 | ||||

|

Calculation Formula

Weight per meter (kg) = π × (Diameter (mm) / 2)² × Length (mm) × Density (g/cm³) / 1,000,000.

Since length is 1000 mm, simplified to: Weight per meter (kg) = π × (Diameter (mm)/2)² × 1000 × Density (g/cm³) / 1,000,000.

Weight per meter (kg) = π × (Diameter (mm) / 2000)² × 1 (meter) × (Density (g/cm³) × 1000) (kg/m³). For this table (Density 1.40 g/cm³): Weight per meter (kg) ≈ 3.14159 × (Diameter (mm) / 2000)² × 1400. |

|||||||

Typical Applications of PI Rods

Leveraging their comprehensive excellent properties, PI rods are widely used to manufacture various high-performance precision components:

Aerospace & Defense Industry

Small high-temperature resistant structural parts, bushings, seals, connector components, military fiber optic protective tubing components.

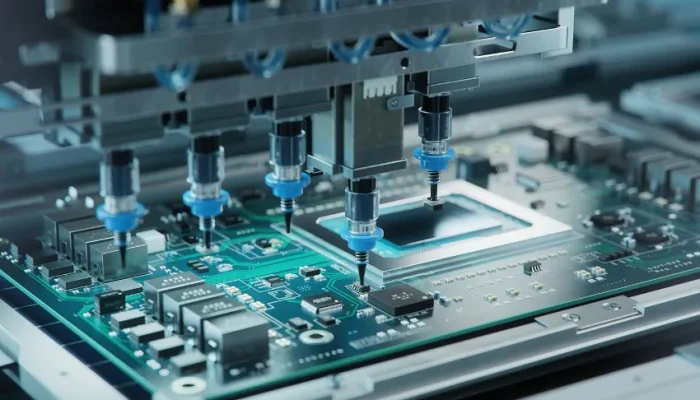

Semiconductor & Electronics Industry

Probe guides for IC test sockets, wafer handling components, vacuum pen tips, coil bobbins, insulation spacers, bolts, and nuts.

Nuclear Power & Energy Sector

Fasteners, insulation parts, and small valve components in radiation-resistant environments.

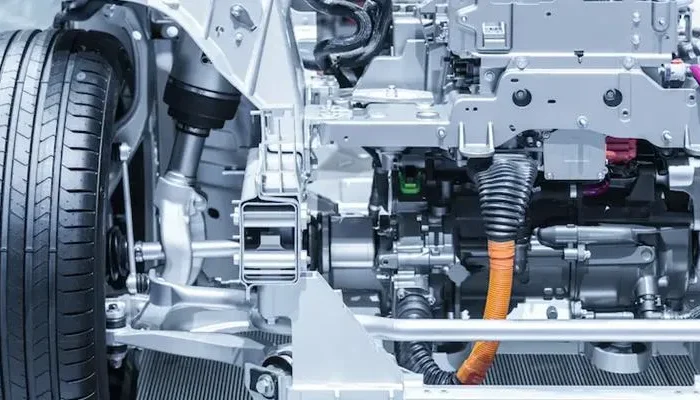

Automotive Industry

High-temperature engine components, transmission thrust washers, small rollers or pins for bearing cages, sensor components.

Industrial Machinery

High-load sliding bearings, bushings, precision guide pins, valve seats, seal rings, bolts, nuts, damping components in high-end audio equipment.

Medical Devices

Components requiring high-temperature sterilization resistance and biocompatibility (specific grades).

Precision Instruments

Micro-components with high dimensional stability requirements, thermal insulation parts.

Calculation Formula: Weight per meter (kg) = π * (Diameter (mm) / 2)² * Length (mm) * Density (g/cm³) / 1,000,000. Since length is 1000mm, simplified to: Weight per meter (kg) = π * (Diameter (mm) / 2)² * 1000 * Density (g/cm³) / 1,000,000. Weight per meter (kg) = π * (Diameter (mm) / 2000)² * 1 (meter) * (Density (g/cm³) * 1000) (kg/m³). For this table (Density 1.40 g/cm³): Weight per meter (kg) ≈ 3.14159 * (Diameter (mm) / 2000)² * 1400

Key Properties of Unfilled PI Rods

Unfilled PI rods offer excellent thermal stability, chemical resistance, and high mechanical strength, making them ideal for demanding engineering applications.

|

Property |

Unit |

Reference Value (Range) |

Test Standard (Example) |

|---|---|---|---|

|

Density |

g/cm³ |

1.38 - 1.43 |

ISO 1183 |

|

Tensile Strength |

MPa |

80 - 120 |

ISO 527 |

|

Elongation at Break |

% |

5--15 |

ISO 527 |

|

Flexural Modulus |

GPa |

3.0 - 4.5 |

ISO 178 |

|

Heat Deflection Temp (HDT, 1.8MPa) |

°C |

260 - 300+ |

ISO 75 |

|

Continuous Service Temp. |

°C |

≥ 260 |

- |

|

Volume Resistivity |

Ω·cm |

> 10¹⁶ |

IEC 60093 |

|

Dielectric Strength |

kV/mm |

> 20 |

IEC 60243 |

Note: The data above is for reference only. For detailed performance parameters of specific products, please contact our technical support or request a product specification sheet. Dalian Allstar Material offers PI rods in various diameters and lengths from our factory and can perform precision machining according to drawings, meeting specific exterior finish and tolerance requirements.

Looking for high-performance PI rods for your precision components?

Dalian Allstar Material is your trusted PI material and machining partner in China. We offer PI rods from standard specifications to customized modifications, along with high-precision manufacture and machining services.