Exceptional Properties of Allstar Material's Polyimide (PI) Sheets

Our PI sheets, due to their unique molecular structure, possess the following performance advantages:

High-Temperature Resistance

Capable of long-term stable operation over a wide temperature range from -269°C to +260°C (can reach higher temperatures, e.g., 400°C, for short periods).

Excellent Mechanical Properties

Maintains high strength, high modulus, and good creep resistance even at elevated temperatures.

Outstanding Dimensional Stability

Features an extremely low coefficient of thermal expansion and low moisture absorption, ensuring precise dimensions in complex environments.

Good Chemical Corrosion Resistance

Exhibits good tolerance to most organic solvents, oils, and weak acids.

Electrical Insulation Performance

High dielectric strength and stable dielectric constant make it an ideal electrical insulation material.

Inherent Flame Retardancy

Achieves high flame retardant ratings (e.g., UL94 V-0) without the addition of flame retardants.

Radiation Resistance

Maintains its physical properties even under high-dose radiation environments.

Good Wear Resistance

Especially after specific modifications, it exhibits excellent wear resistance and low friction characteristics.

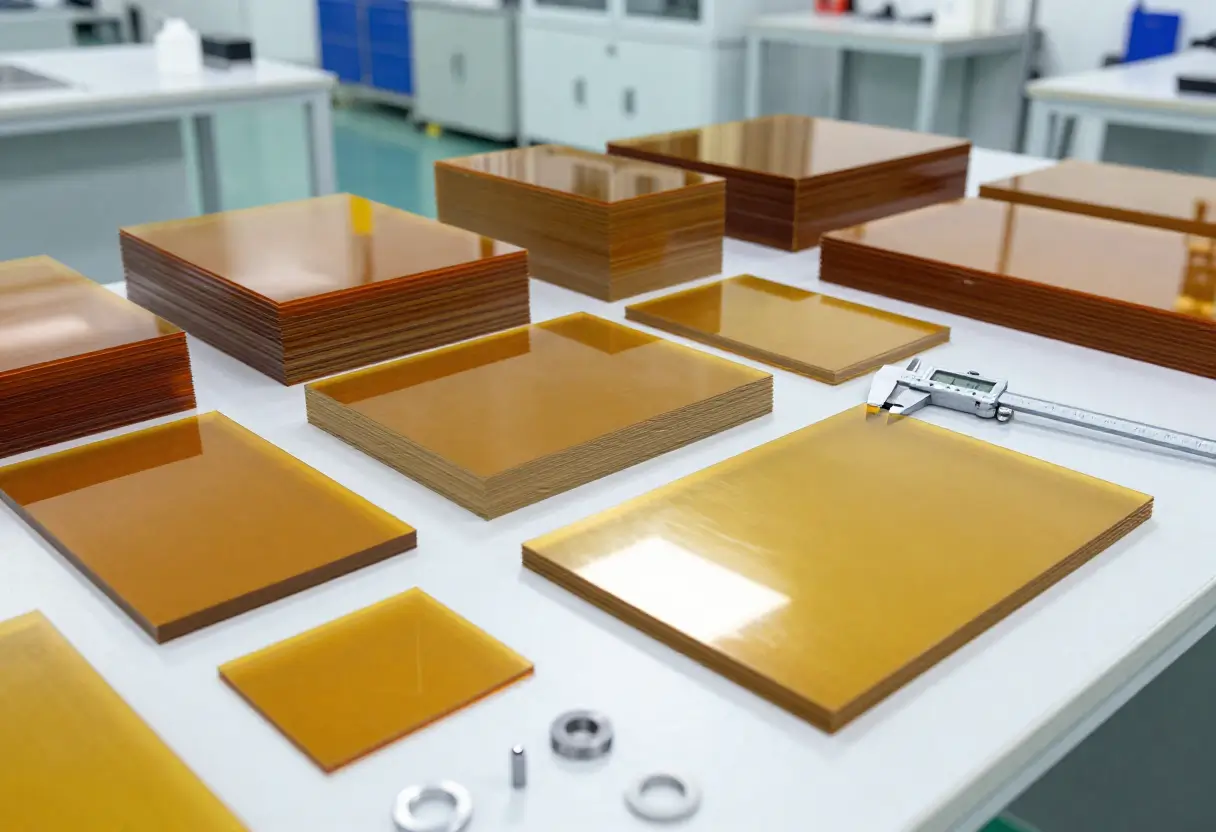

Classification of Allstar Material's PI Sheets

To meet the specific needs of different application scenarios, our PI sheets are primarily categorized as follows:

Unfilled/Pure PI Sheets

Made from pure polyimide resin, fully demonstrating the inherent basic properties of PI material.

Suitable for applications with high requirements for material purity and electrical insulation.

Modified/Reinforced PI Sheets

Pure PI is modified by adding specific fillers (e.g., graphite, PTFE, glass fiber, carbon fiber) to enhance specific material properties.

Enhanced Mechanical Strength & Rigidity (e.g., glass fiber/carbon fiber reinforced).

Improved Wear Resistance & Reduced Friction Coefficient (e.g., graphite/PTFE filled).

Increased Thermal Conductivity or Electrical Conductivity/Antistatic Properties (e.g., specific carbon-based fillers).

Dalian Allstar Material can provide customized modified PI sheet solutions based on specific customer operating conditions, available for wholesale. Contact

Allstar Material Available Sizes and Stock (from our factory)

We offer a wide range of Allstar material sizes with reliable stock directly from our factory to meet your project needs.

| THICKNESS (mm) | WIDTH (mm) | LENGTH (mm) | DENSITY (g/cm³) | WEIGHT PER METER (kg) | THICKNESS (mm) | WIDTH (mm) | LENGTH (mm) | DENSITY (g/cm³) | WEIGHT PER METER (kg) |

|---|---|---|---|---|---|---|---|---|---|

| 0.5 | 520 | 1000 | 1.4 | 0.364 | 20 | 520 | 1000 | 1.4 | 14.56 |

| 0.6 | 520 | 1000 | 1.4 | 0.437 | 22 | 520 | 1000 | 1.4 | 16.016 |

| 0.8 | 520 | 1000 | 1.4 | 0.582 | 25 | 520 | 1000 | 1.4 | 18.2 |

| 1 | 520 | 1000 | 1.4 | 0.728 | 28 | 520 | 1000 | 1.4 | 20.384 |

| 1.2 | 520 | 1000 | 1.4 | 0.874 | 30 | 520 | 1000 | 1.4 | 21.84 |

| 1.5 | 520 | 1000 | 1.4 | 1.092 | 32 | 520 | 1000 | 1.4 | 23.296 |

| 1.6 | 520 | 1000 | 1.4 | 1.165 | 35 | 520 | 1000 | 1.4 | 25.48 |

| 1.8 | 520 | 1000 | 1.4 | 1.31 | 40 | 520 | 1000 | 1.4 | 29.12 |

| 2 | 520 | 1000 | 1.4 | 1.456 | 45 | 520 | 1000 | 1.4 | 32.76 |

| 2.5 | 520 | 1000 | 1.4 | 1.82 | 50 | 520 | 1000 | 1.4 | 36.4 |

| 3 | 520 | 1000 | 1.4 | 2.184 | 55 | 520 | 1000 | 1.4 | 40.04 |

| 3.5 | 520 | 1000 | 1.4 | 2.548 | 60 | 520 | 1000 | 1.4 | 43.68 |

| 4 | 520 | 1000 | 1.4 | 2.912 | 65 | 520 | 1000 | 1.4 | 47.32 |

| 5 | 520 | 1000 | 1.4 | 3.64 | 70 | 520 | 1000 | 1.4 | 50.96 |

| 6 | 520 | 1000 | 1.4 | 4.368 | 75 | 520 | 1000 | 1.4 | 54.6 |

| 7 | 520 | 1000 | 1.4 | 5.096 | 80 | 520 | 1000 | 1.4 | 58.24 |

| 8 | 520 | 1000 | 1.4 | 5.824 | 85 | 520 | 1000 | 1.4 | 61.88 |

| 10 | 520 | 1000 | 1.4 | 7.28 | 90 | 520 | 1000 | 1.4 | 65.52 |

| 12 | 520 | 1000 | 1.4 | 8.736 | 95 | 520 | 1000 | 1.4 | 69.16 |

| 15 | 520 | 1000 | 1.4 | 10.92 | 100 | 520 | 1000 | 1.4 | 72.8 |

| 16 | 520 | 1000 | 1.4 | 11.648 | 105 | 520 | 1000 | 1.4 | 76.44 |

| 18 | 520 | 1000 | 1.4 | 13.104 | |||||

| Calculation Formula Weight per meter (kg) = Thickness (mm) / 1000 × Width (mm) / 1000 × Length (mm) / 1000 × Density (g/cm³) × 1000. Since length is 1000 mm (1 meter), density unit g/cm³ converted to kg/m³ is multiplied by 1000. Simplified to: Weight per meter (kg) = Thickness (mm) × Width (mm) × Density (g/cm³) / 1000. For this table (Width 520 mm, Density 1.40 g/cm³): Weight per meter (kg) = Thickness (mm) × 520 × 1.40 / 1000, i.e. Weight per meter (kg) = Thickness (mm) × 0.728. | |||||||||

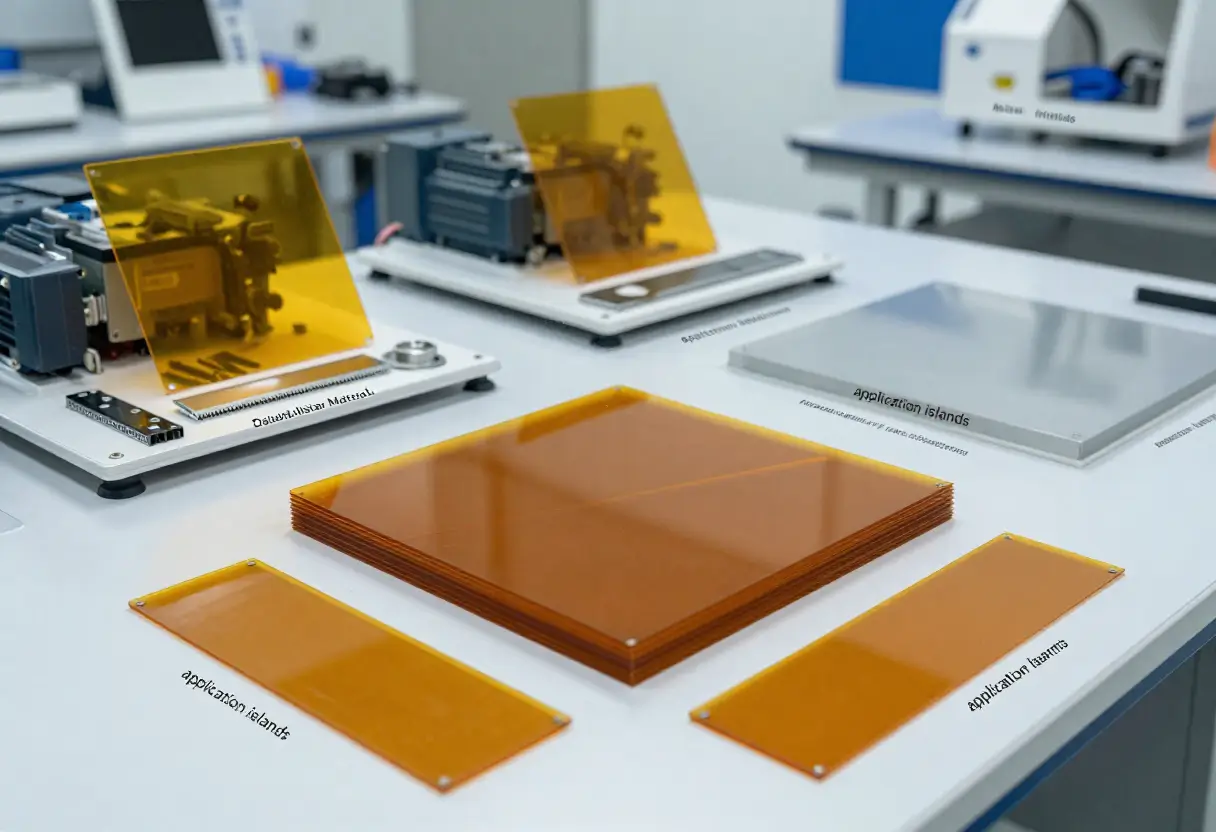

Typical Applications of Polyimide (PI) Sheets

Thanks to their comprehensive performance advantages, PI sheets are widely used in demanding industrial fields:

Aerospace & Defense Industry

Engine components, missile parts, high-temperature resistant structural parts, thermal barrier coatings, military fiber optic coatings.

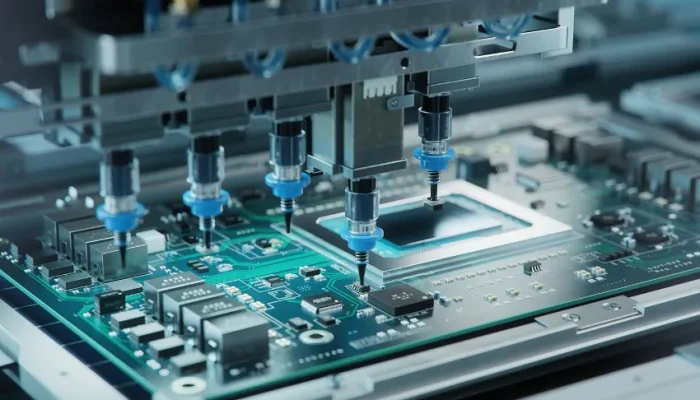

Semiconductor & Electronics Industry

Wafer chucks, IC test sockets, LCD manufacturing process components, coil bobbins, flexible printed circuit (FPC) substrates, electric vehicle insulation paper.

Nuclear Power & Energy Sector

Radiation-resistant insulation layers for nuclear power cables, seals for high-temperature and high-pressure environments.

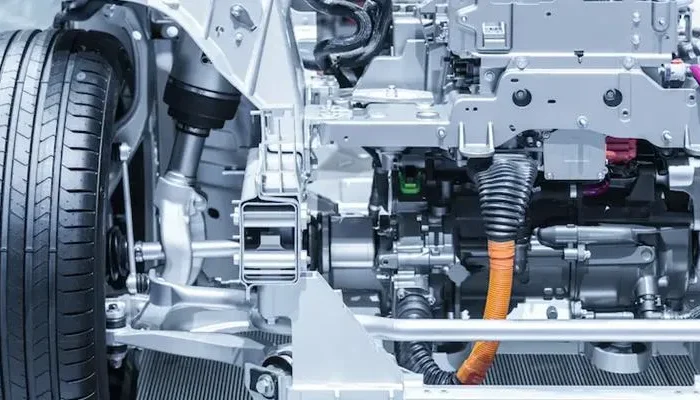

Automotive Industry

High-temperature resistant components in engine compartments, transmission thrust washers, bearing cages, turbocharger components.

Industrial Machinery

High-load sliding bearings, bushings, piston rings, valve seats, seals, high-end audio diaphragms. An excellent exterior finish can be achieved.

Precision Instruments

Structural parts requiring high dimensional stability, thermal insulation parts.

Seeking High-Performance PI Sheet Solutions?

Dalian Allstar Material is your reliable partner. We offer one-stop services from standard PI sheets to customized modified PI sheets and precision machining from our factory in China.