Exceptional Properties of PI Tubes

PI tubes fully demonstrate the inherent excellent characteristics of polyimide material. Their specific performance indicators typically include:

Exceptional Temperature Range

Capable of long-term stable operation within an extremely wide temperature range from -269°C to +260°C. Short-term operating temperatures for some special grades can reach 300°C or even higher. Their glass transition temperature (Tg) is usually above 250°C, and the heat deflection temperature (HDT @1.8MPa) can reach 260 - 300+°C.

Excellent Mechanical Strength

The material maintains high mechanical performance at elevated temperatures, with tensile strength typically ranging from 80 to 120 MPa (higher for reinforced grades), flexural strength between 110 and 180 MPa, and excellent compressive strength under high loads. It also offers high rigidity, with a flexural modulus of 3.0 to 4.5 GPa, and good creep resistance, showing minimal deformation under continuous stress.

Outstanding Dimensional Stability

Extremely Low Coefficient of Thermal Expansion (CLTE): Linear expansion coefficient is typically in the range of (20-50) x 10⁻⁶ /K, ensuring minimal dimensional change during temperature fluctuations.

Extremely Low Water Absorption: 24-hour water absorption is usually less than 0.5% (ISO 62), providing good dimensional stability in humid environments.

Good Chemical Corrosion Resistance

Shows good resistance to most organic solvents (such as alcohols, ethers, ketones, hydrocarbons), oils, fuels, and weak acids. Note that strong alkalis and strong oxidizing acids may affect it.

Prominent Electrical Insulation Performance:

High Dielectric Strength: Typically greater than 20 kV/mm (IEC 60243). High Volume Resistivity: Generally greater than 10¹⁶ Ω·cm (IEC 60093), making it an excellent insulation material. Stable Dielectric Constant and Low Dielectric Loss: Remains stable over a wide range of frequencies and temperatures.

Inherent Flame Retardancy

Most pure PI materials can achieve UL94 V-0 flame retardancy rating without adding flame retardants, with low smoke emission during combustion.

Excellent Radiation Resistance

Can withstand high doses of ionizing radiation such as γ-rays and X-rays without significant performance degradation, with a tolerance dose of up to 10⁷ - 10⁹ rads.

Good Machinability

Can undergo secondary machining processes such as precision turning, drilling, milling, tapping, and cutting to achieve precise dimensions and smooth exterior surfaces.

Wear-Resistant Properties

Pure PI has a certain degree of self-lubrication. After modification by adding fillers like graphite or PTFE, its friction coefficient can be significantly reduced (as low as 0.1-0.2), and wear resistance is greatly improved, making it suitable for manufacturing tubular moving parts requiring low friction and high wear resistance, such as precision bushings and guide tubes.

Classification of PI Tubes

To meet the specific performance requirements of different application scenarios, PI tubes are mainly classified as follows:

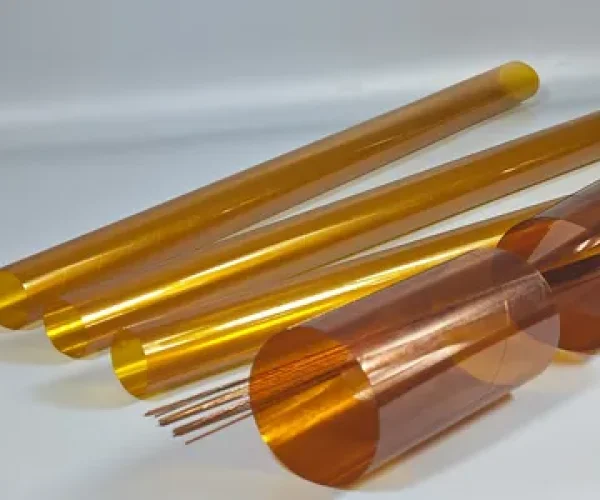

Unfilled/Pure PI Tubes

Made from pure polyimide resin, showcasing the fundamental superiority of PI material.

Often used in fields with high standards for material purity and electrical insulation performance.

Reinforced PI Tubes

Specific properties are optimized by uniformly dispersing specific fillers (such as graphite, PTFE, glass fiber, carbon fiber, etc.) in the polyimide matrix.

Main modification directions include:

Enhancing mechanical strength and rigidity (e.g., glass fiber/carbon fiber reinforced, used for structural support tubes). Improving wear resistance and reducing friction coefficient (e.g., graphite/PTFE filled, used for manufacturing precision bushings, guide tubes). Improving thermal conductivity or imparting conductive/antistatic properties (for specific application needs).

Dalian Allstar Material can provide customized modified PI tube solutions based on specific customer operating conditions and performance indicators, available for wholesale.

Allstar Material PI Tube Supply Range (from our factory)

Allstar Material offers a comprehensive range of high-quality PI (Polyimide) tubes directly from our factory, ensuring precision, durability, and performance for various industrial and engineering applications.

|

PI Tube Supply Range |

|

|---|---|

|

Inner Diameter (ID) |

12 - 138 mm |

|

Outer Diameter (OD) |

23 - 230 mm |

|

Length |

Custom (Per customer requirements) |

Typical Applications of PI Tubes

Due to their high performance, PI tubes are widely used in the manufacture of various tubular components for harsh environments:

Aerospace & Defense

Sensor protection sleeves, small hydraulic/pneumatic tubing components, high-temperature cable sheaths, precision tubing for military fiber optics.

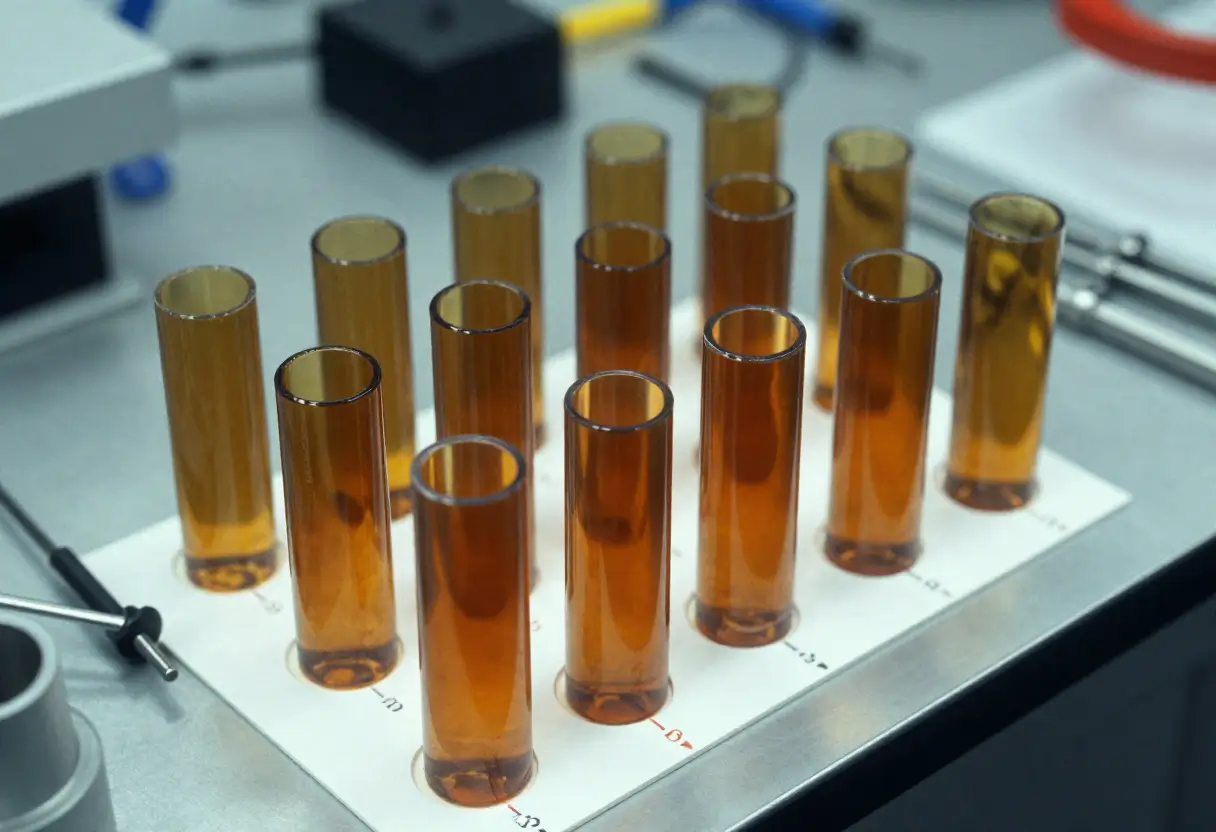

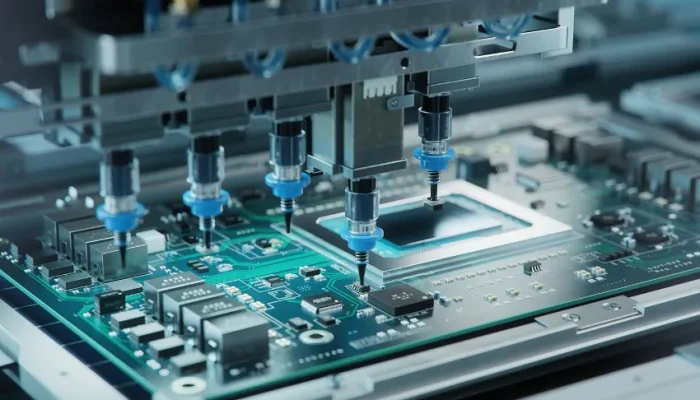

Semiconductor & Electronics Industry

High-purity fluid transport tubes, high-temperature resistant sleeves in chip manufacturing processes, probe protection tubes, electrical insulation sleeves.

Medical Devices

Miniature catheter components requiring high-temperature sterilization, sample transfer tubes in analytical instruments (biocompatible grades need to be considered).

Precision Instruments

Chromatography column tubes, high-temperature gas/liquid transport tubes, protective sleeves in optical instruments.

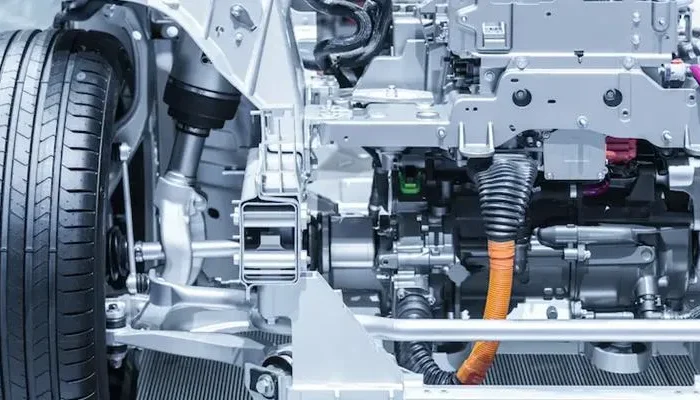

Automotive & Transportation

High-temperature sensor sleeves in engine compartments, specific fittings in fuel systems, wear-resistant bushings in braking systems.

Industrial Equipment

Instrument protection tubes in high-temperature and high-pressure environments, linings for corrosive media transport pipes, precision bushings in sliding bearings.

Energy Sector

Radiation-resistant sleeves in nuclear power plants, sensor protection tubes in high-temperature and high-pressure environments.

Looking for high-performance, high-reliability PI tubes for your application?

Dalian Allstar Material is your ideal partner for PI tubes and precision machining in China. We offer PI tubes from standard specifications to complex modifications, as well as high-precision secondary processing services.