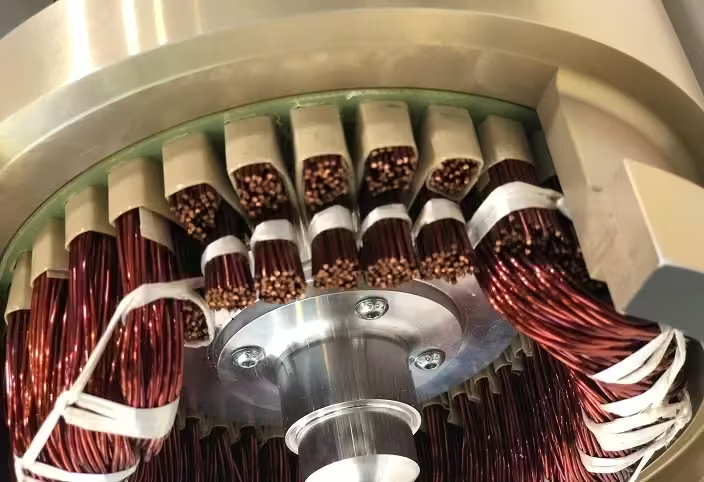

Electric Vehicles: In electric vehicle batterymodules, motor windings, and high-voltagedistribution systems, PEEK cables are used to enhanc!electric vehicle safety, efficiency, and lifespan dueto their high temperature resistance, high voltageinsulation, and flame retardant characteristics.0il and Gas(Downhole Applications):In deep seadrilling, high temperature high pressure oil and gasdownhole exploration and production equipment, PEEKcables serve as sensor cables, data transmissionlines, and power cables, capable of resisting extremtemperatures, high pressure fluids, and variouscorrosive chemical erosion, ensuring long-term stabloperation.