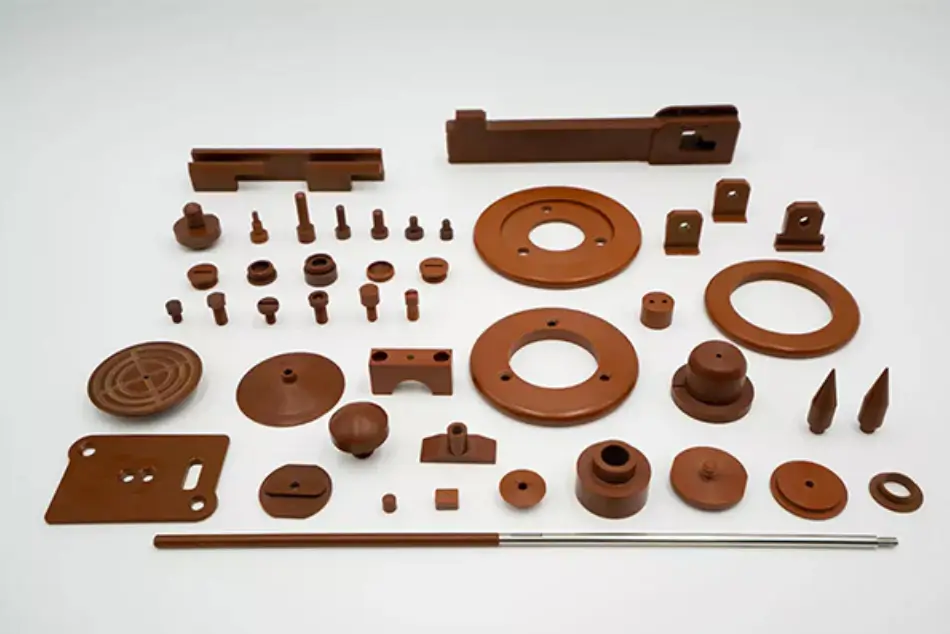

Dalian Allstar Material

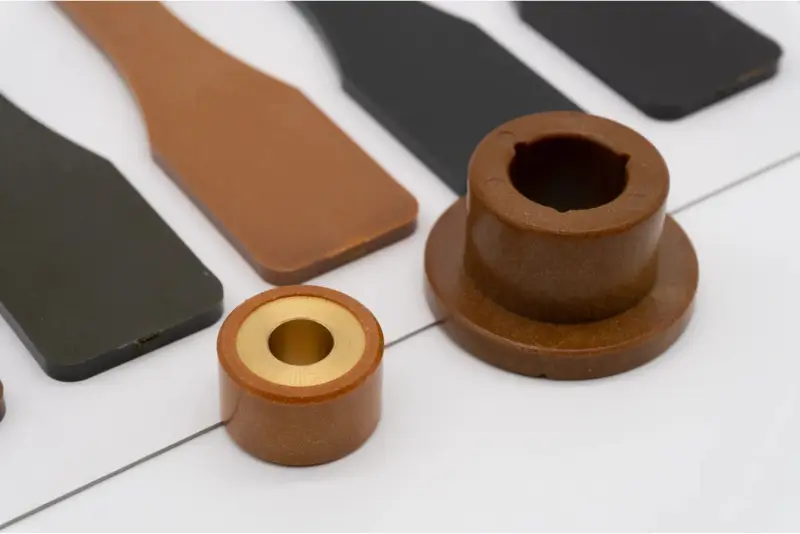

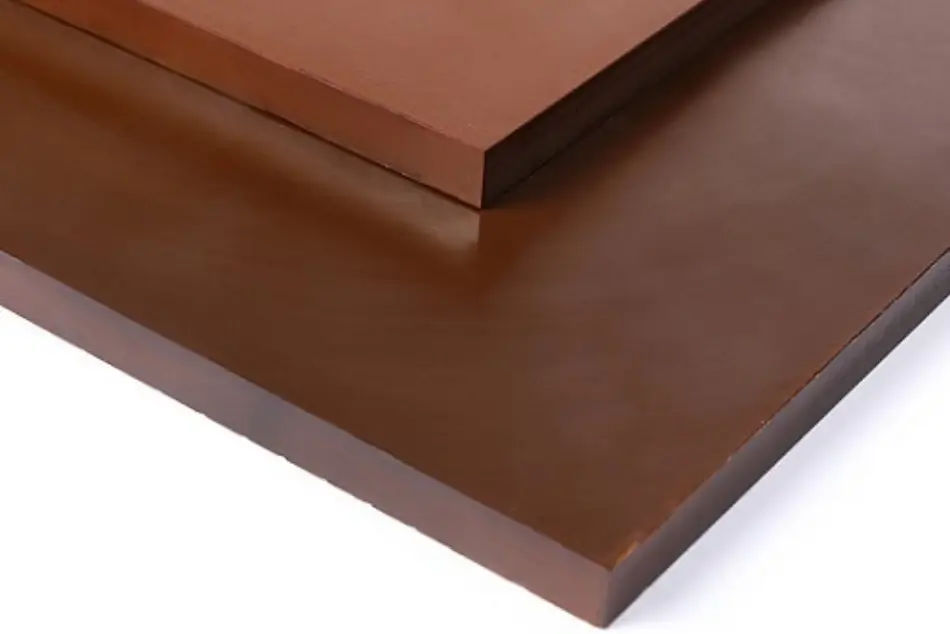

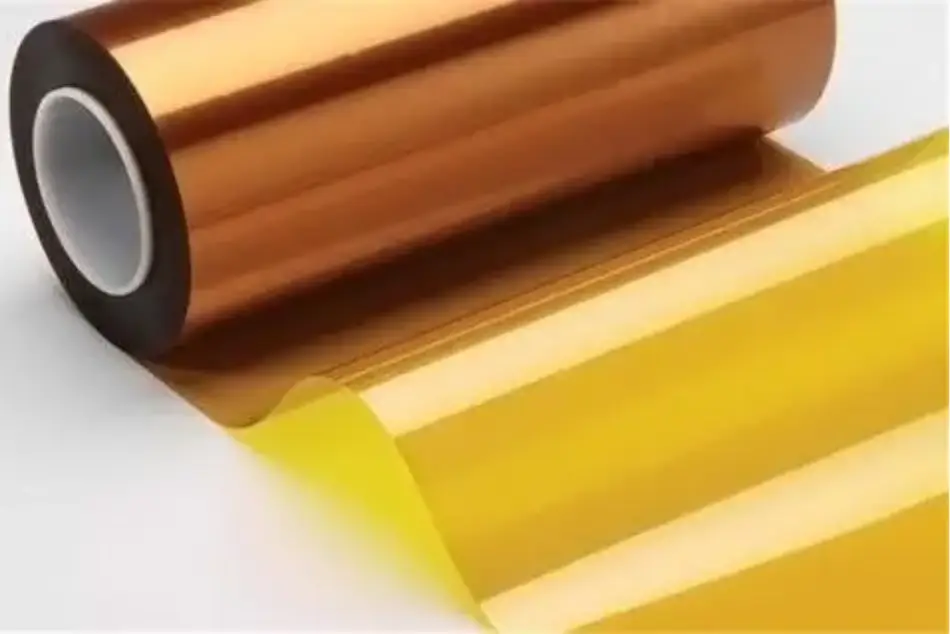

Polyimide (PI) Material China manufacture Dalian Allstar Material

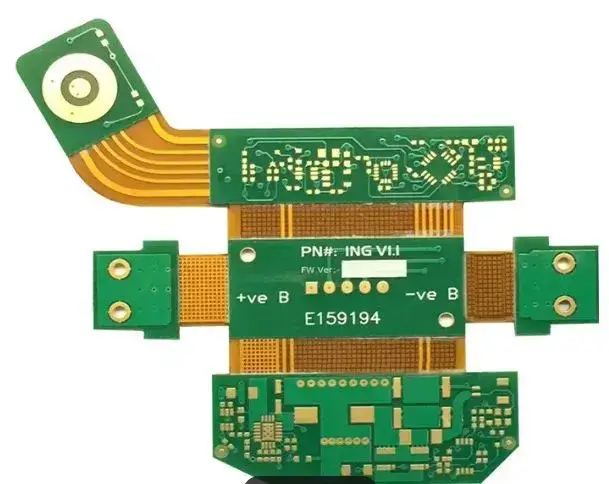

Polyimide (PI) is a high-performance engineering plastic based on imide monomers, with short-term use temperature above 400°C, long-term temperature range from -269°C to 300°C, some with no obvious melting point, high insulation performance, low dielectric constant and other characteristics.