Performance Advantage Analysis of Allstar Material's Thermoset Polyimide

High temperature resistance

The glass transition temperature (Tg) of thermosetting polypropylene (PI) is typically 250–400 °C.

Decomposition temperature (5% weight loss) is generally 500–600 °C (in air or nitrogen).

It can still be used continuously for extended periods at 250–300 °C, while most engineering plastics (such as PEEK and PEI) show a significant performance degradation above 250 °C.

Excellent mechanical properties (especially at high temperatures)

Tensile strength: 100–200 MPa (according to test standard ASTM D638).

Flexural strength: 120–250 MPa.

Modulus of elasticity: 2.5–5.0 GPa.It retains high strength at high temperatures, for example, at 200–250 °C, the strength retention rate can reach 70–80%.

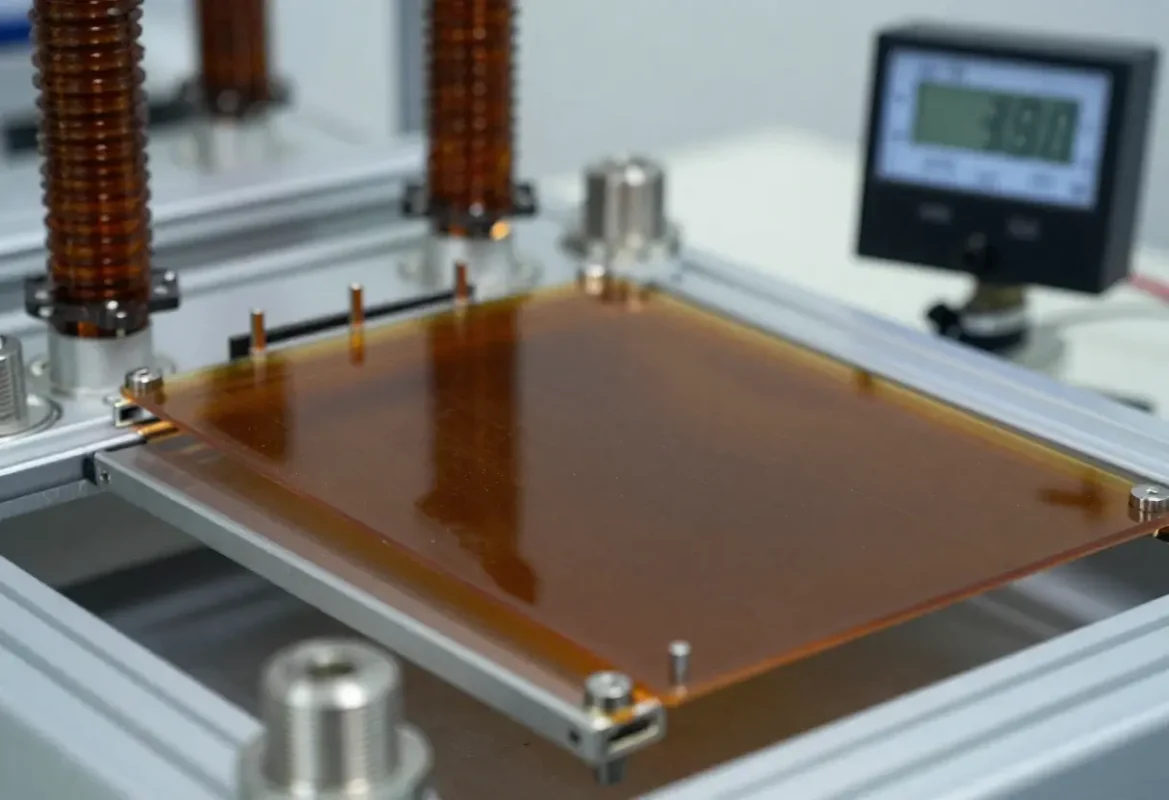

Outstanding electrical performance

Dielectric constant (1 kHz, 25℃): Approximately 3.0–3.5.

Dielectric loss factor: Approximately 10⁻³–10⁻², very low.

Insulation breakdown strength: Approximately 100–300 kV/mm.”

Chemical corrosion resistance

Good dimensional stability

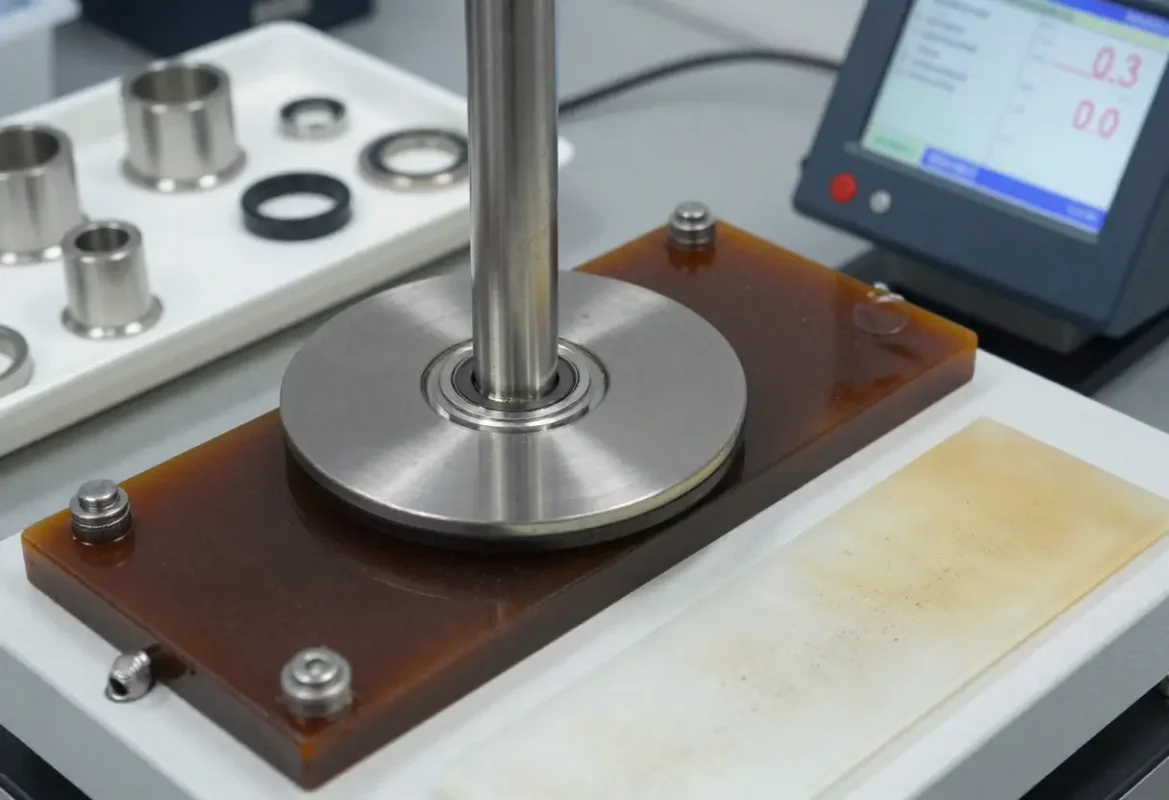

Wear-resistant

Typical Application Fields of Thermoset PI

Aerospace Field

Electronics and Semiconductor Industry

with its excellent electrical properties and dimensional stability, it is used to manufacture test sockets for high-performance integrated circuits, wafer processing components, high-frequency connectors, flexible printed circuit (FPC) substrates, as well as high-temperature coil bobbins and wire insulation layers.

Automotive Electrical Systems

Processing of Thermoset PI

Compression Molding

Compression Molding (Direct Forming) is the primary method. PI powder or prepolymer is typically used, undergoing pressure holding and curing under high temperature (curing temperature usually needs to be raised in stages to 300°C - 400°C, or even higher) and high pressure (typical pressure 30 - 70 MPa or higher) conditions. This process involves imidization and crosslinking chemical reactions, taking considerable time (usually several hours) to form an irreversible crosslinked structure and obtain the final excellent properties.

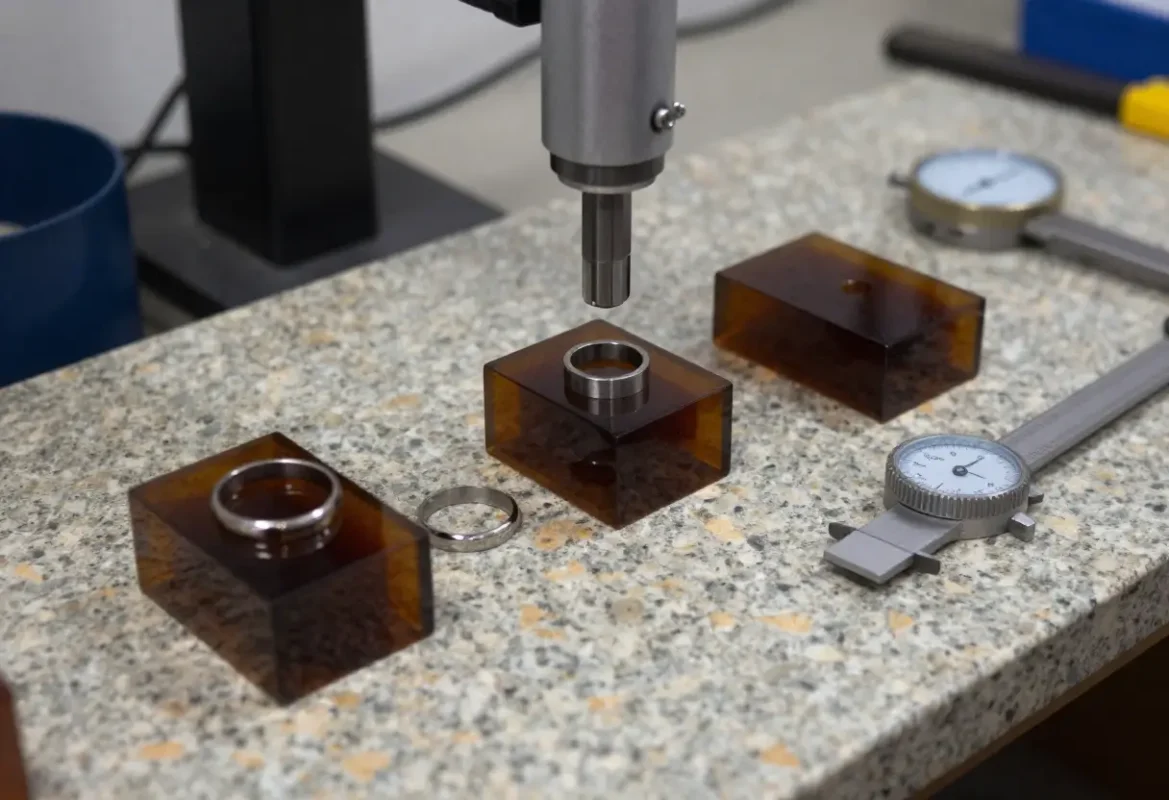

Precision Machining

Precision Machining is also a critical process. Since Thermoset PI is usually supplied in semi-finished forms such as sheets and rods, final parts are often obtained through turning, milling, drilling, and other methods. Due to its high hardness and certain abrasiveness, carbide or diamond tools must be used during processing. At the same time, cutting speed and feed rate must be controlled (for example, recommended linear speed is usually below 60 m/min) to prevent overheating that could cause material cracking or performance degradation. Coolant is generally not recommended, or specific types must be selected.